Pre-mixing device used for lyocell fiber preparation

A premixer and fiber technology, applied in the direction of feeding the solution to the spinneret, etc., can solve the problems of uneven upper and lower mixing, fast outflow of liquid medium, and white core formation, so as to avoid the decline of fiber quality and improve the effect of fiber quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

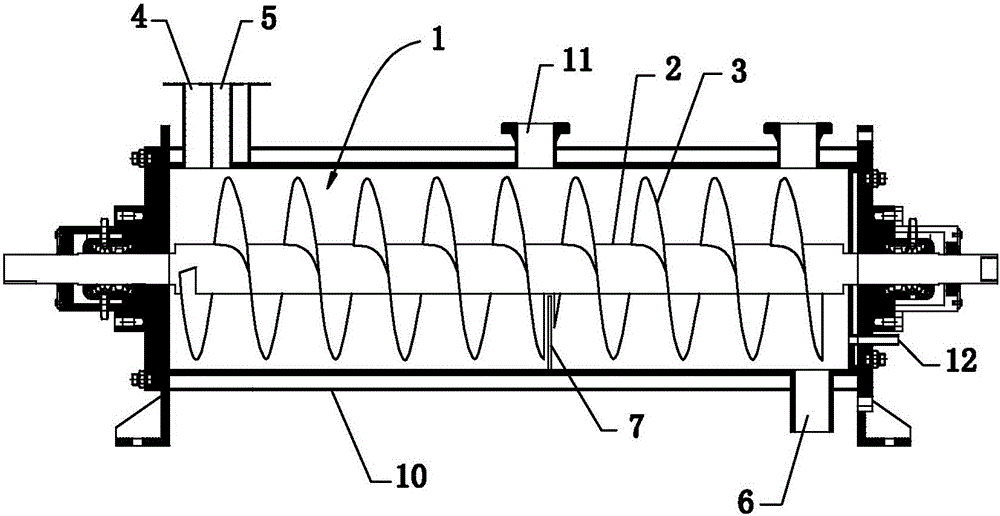

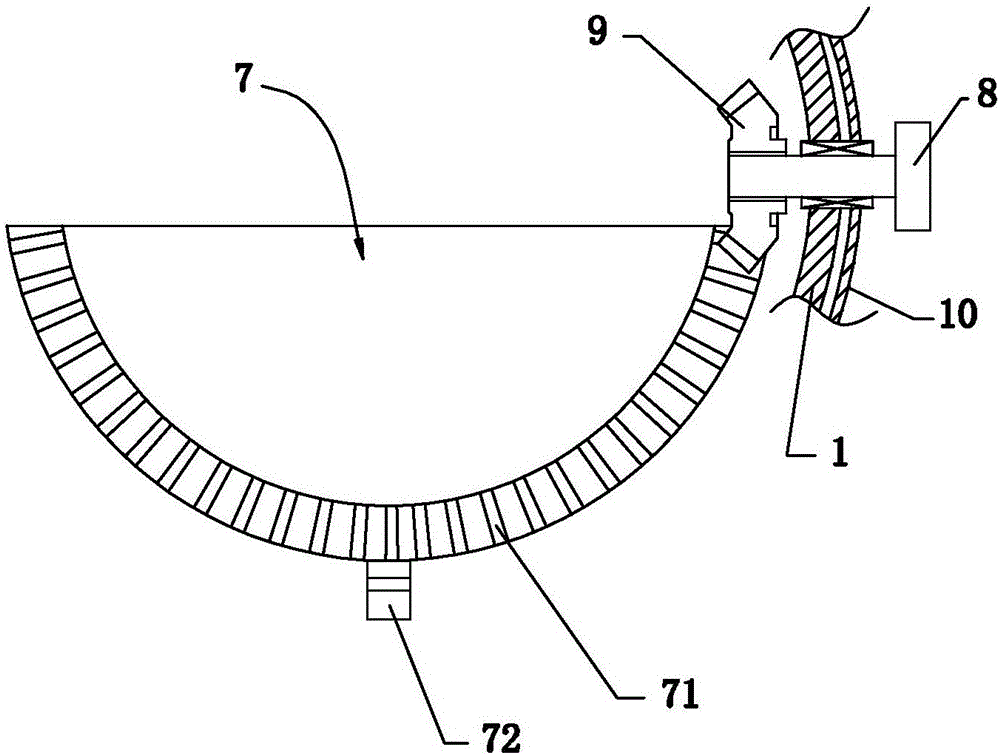

[0029] Such as figure 1 with figure 2 Commonly shown, a premixer for lyocell fiber preparation includes a premixer body 1 arranged horizontally, specifically, the inner diameter of the premixer body is 20-30 cm, and the length is 50-500 cm. 1 is provided with a stirring screw 2 along the axial direction, and a propeller blade 3 is provided on the stirring screw 2. The pulp material inlet 4 and the solvent and additive inlet 5 are arranged on the top of one end of the premixer body 1, and the bottom of the other end is provided with a row The feed opening 6, the pre-mixer body 1 is provided with a baffle 7 which slides along the circumferential direction, the propeller blade 3 is provided with a gap for accommodating the baffle 7, and the pre-mixer body 1 is provided with an adjustment mechanism for controlling the sliding of the baffle 7.

[0030] In this embodiment, the inner wall of the pre-mixer body 1, the stirring screw 2, the propeller blade 3 and the surface of the ba...

Embodiment 2

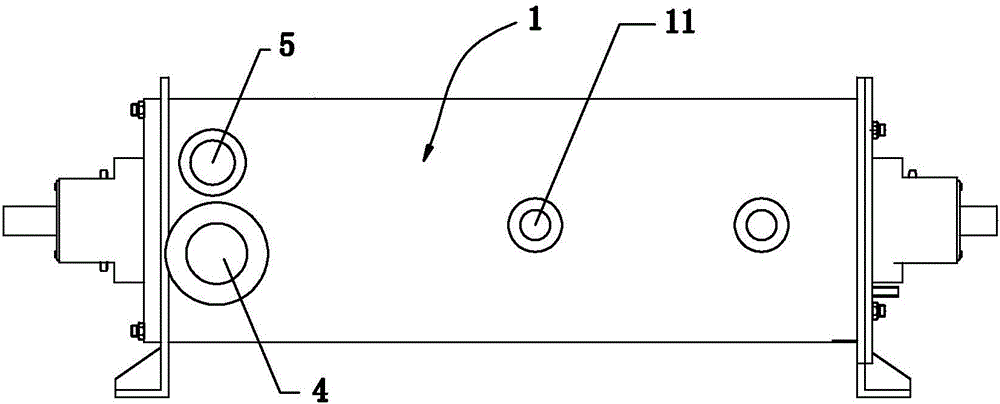

[0038] Such as image 3As shown, this embodiment has basically the same structure as Embodiment 1, the difference is that the pulp material inlet 4 and the solvent and additive inlet 5 are arranged close to each other, specifically, the pulp material inlet 4 and the solvent and additive inlet 5 Arranged side by side on the 1st circumference of the pre-mixer body.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com