Connector with prefabricated steel pipe concrete beam segment and connecting method thereof

A technology of steel pipe concrete and connection method, which is applied in the direction of construction and building construction, etc., which can solve the problems of inability to ensure the compactness of the internal concrete, indirect force transmission in the splicing area, and increased construction difficulty, so as to improve the construction quality and have little impact on the surrounding environment , Improve the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structure, processing and use of the present invention will be further described below in conjunction with the accompanying drawings.

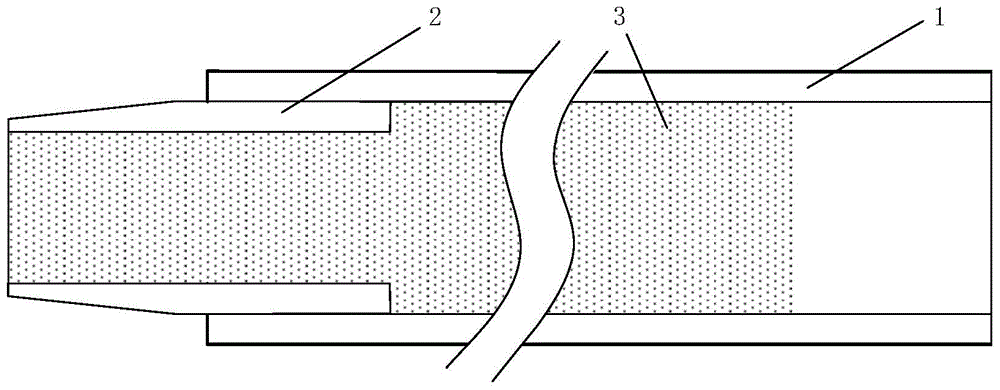

[0018] A connector of a prefabricated steel pipe concrete beam section of the present invention, the connector is a tapered inner steel pipe 2, which is welded in one end of the outer steel pipe, such as image 3 shown. The length of the tapered inner steel pipe protruding from the outer steel pipe meets the requirements of the steel pipe being embedded in the steel pipe for bending transmission.

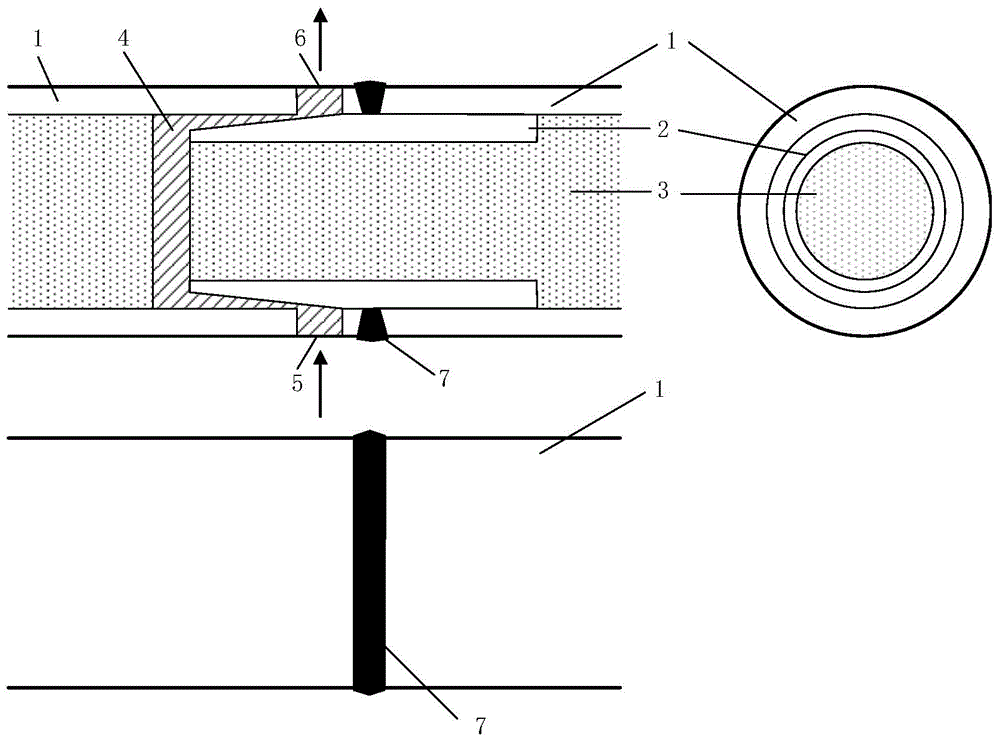

[0019] figure 1 Shown is the overall schematic diagram of the present invention.

[0020] The specific construction steps of the connection method of the prefabricated steel pipe concrete beam section of the present invention are as follows:

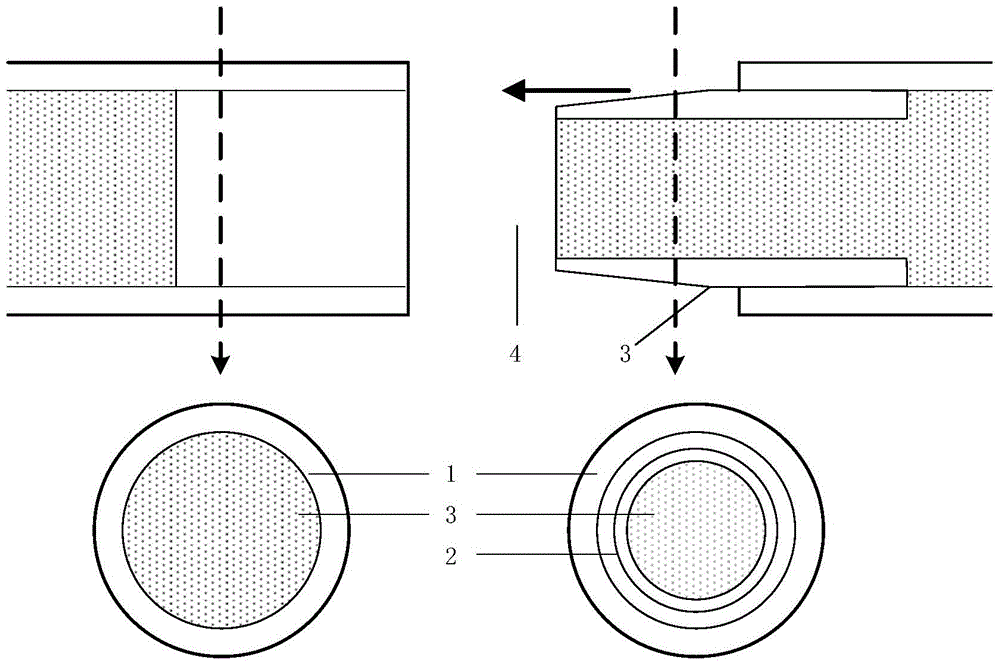

[0021] 1) Prefabrication of CFST beam segments in factories (such as image 3 As shown), the section includes a prefabricated reinforced concrete outer steel pipe 1, a tapered inner steel pipe 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com