High-strength concrete block used as outer wall of grouted composite wall as well as grouted composite wall and construction method thereof

A technology of concrete blocks and composite walls, which is applied in the processing of walls, building materials, building components, etc., can solve the problem of prolonging the construction period, the impact of the durability of the heat insulation performance of the wall, and the insulation of the wall Thermal insulation performance, durability, wall service life and other issues, to achieve the effect of improving overall rigidity, good strength and durability, and improving masonry leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

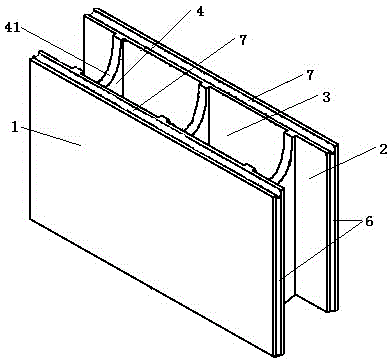

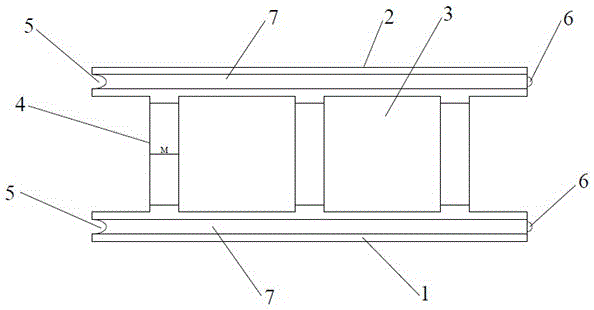

[0076] like figure 1 The high-strength concrete block shown for filling the composite wall is an integrated hollow block made of semi-dry hard concrete composed of the following raw materials: 1100kg fine stone, medium fine sand 900kg, Portland cement P·O42.5250kg, water 90-110kg, fly ash 50kg. The block strength is ≥10MPa, the block wall (rib) is 40mm thick, and the length (L)×height (H)×thickness (B) is 400×190×150 (mm).

[0077] The concrete block includes a front panel 1 and a rear panel 2, which are connected as a whole by three vertically parallel transverse ribs 4, and form two cavities for pouring core material 10 3. The upper part of the transverse rib 4 is provided with a rib hole 41, so that when the blocks are built into wall masonry, the cavities 3 of adjacent blocks communicate with each other, so that the core material from the pouring port or injection port can be placed on the outer wall of the wall. It flows inside and fills the cavity in the outer wall of...

Embodiment 2

[0082] The difference from Example 1 is:

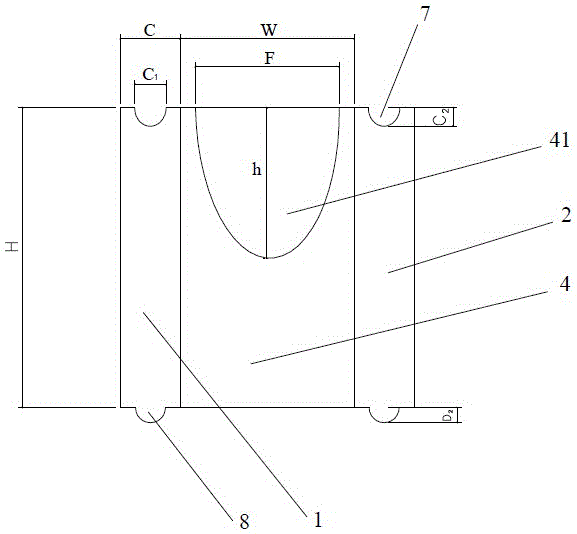

[0083] Concrete blocks are formed by pressing semi-dry hard concrete. Composition of semi-dry hard concrete: fine stone 1000kg, medium fine sand 1100kg, cement 230kg, water 90-110kg, fly ash 50kg. The block strength is ≥10MPa, the block wall (rib) is 30mm thick, and the length (L)×height (H)×thickness (B) is 500×190×190 (mm). The front plate 1 and the rear plate 2 of the block are 30mm thick, and the groove width C of their upper groove 7 1 =18mm, the depth C of the upper groove 7 2 =25mm, lower tenon 8 height D 2 =10mm. The rib hole 41 is an arc hole, the central axis of the hole overlaps with the vertical central axis of the transverse rib plate 4, the maximum width of the rib hole 41 is F=70mm, and the height of the rib hole 41 is h=50mm.

[0084] The core material is made of hydrophobic light bead concrete, composed of light beads (EPS ultra-light particles with a packing density of 4kg / m 3 ), particle size ≤6mm, 4kg; ceme...

Embodiment 3

[0087] The difference from Embodiment 1 is that it is a self-supporting interior wall with a thickness of 120mm and a plaster layer.

[0088] Pressed semi-dry hard concrete. Block strength ≥ 7.5MPa, block wall thickness 40mm, rib thickness 30mm, length (L) × height (H) × thickness (B) is 500 × 190 × 120 (mm), the number of holes is 2, and the outside of the wall is plastered gray layer. The cross section of the upper groove 7 is semicircular, and the groove width is C 1 =25mm, the depth C of the upper groove 7 2 =25mm, lower tenon 8 height D 2 =10mm. The rib hole 41 is an arc hole, the central axis of the hole overlaps with the vertical central axis of the transverse rib plate 4, the maximum width of the rib hole 41 is F=40mm, and the height of the rib hole 41 is h=60mm.

[0089] The core material is made of hydrophobic foam concrete, and the density of foam concrete (kg / m 3 ) 320 ~ 360, the corresponding compressive strength (MPa)> 0.7, the corresponding thermal conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com