Multifunctional oil testing well completion pipe string and method for well prone to blowout and leakage

A completion string and multi-functional technology, applied in the direction of wellbore/well components, drill pipe, casing, etc., can solve the problems of equipment and personnel safety risks, well well pressure difficulties, and reduce the cost of oil testing and completion, etc. Achieve the effects of avoiding mud loss and pollution, reducing the number of tripping operations, and improving the timeliness of oil testing and completion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

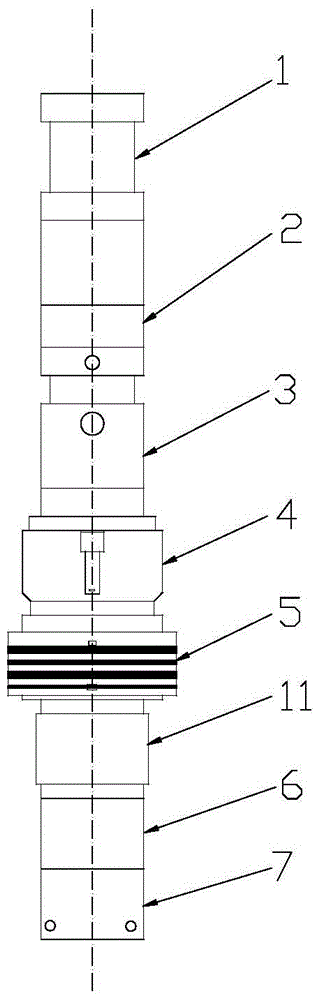

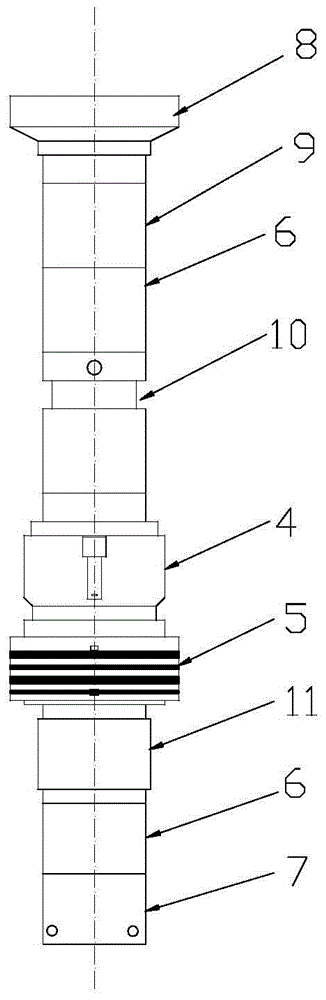

[0025] refer to figure 1 , figure 2 , the practical invention is easy to blow out and easy to leak multifunctional oil testing completion string, including drill pipe 1, expansion joint 2, APC circulation valve 3, anchor seal 4, completion packer 5, tubing 6, pump out type Blocking 7, tubing hanger 8, double male nipple 9, telescopic tube 10, variable buckle joint 11.

[0026] From top to bottom of the feeding pipe string, the drill pipe 1 is connected to the expansion joint 2, the lower end of the expansion joint is connected to the APC circulation valve 3, the lower part of the APC circulation valve 3 is connected to the anchor seal 4, and the lower end of the anchor seal 4 is connected to the completion packer 5 T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com