A kind of support method and support system for roadway in weakly cemented stratum

A technology for roadway support and weak cementation, applied in tunnels, tunnel linings, underground chambers, etc., can solve problems such as large damage range, restrict safety production, and large deformation of surrounding rock, achieve wide popularization and application value, and improve support The effect of high strength and support resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The technical solution of the present invention will be further described below in conjunction with specific embodiments.

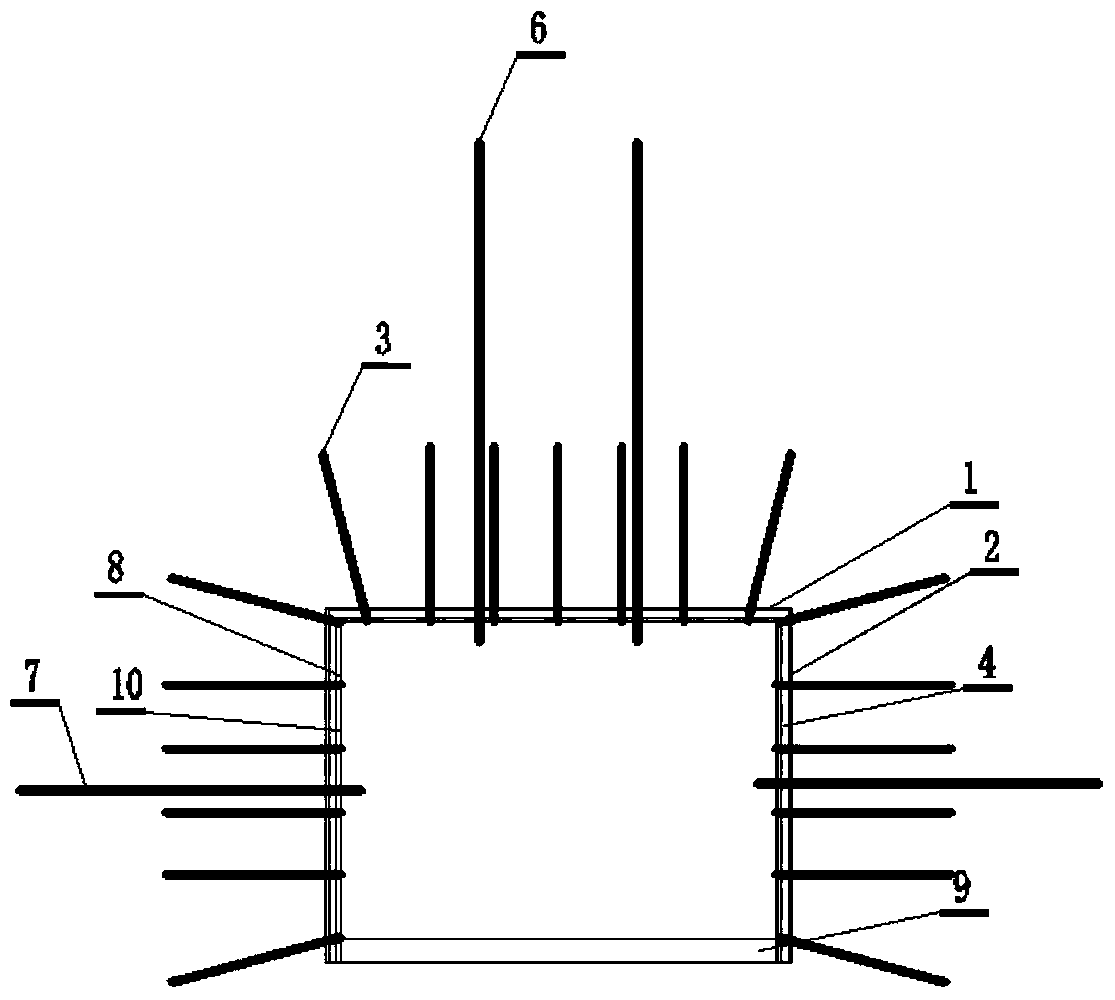

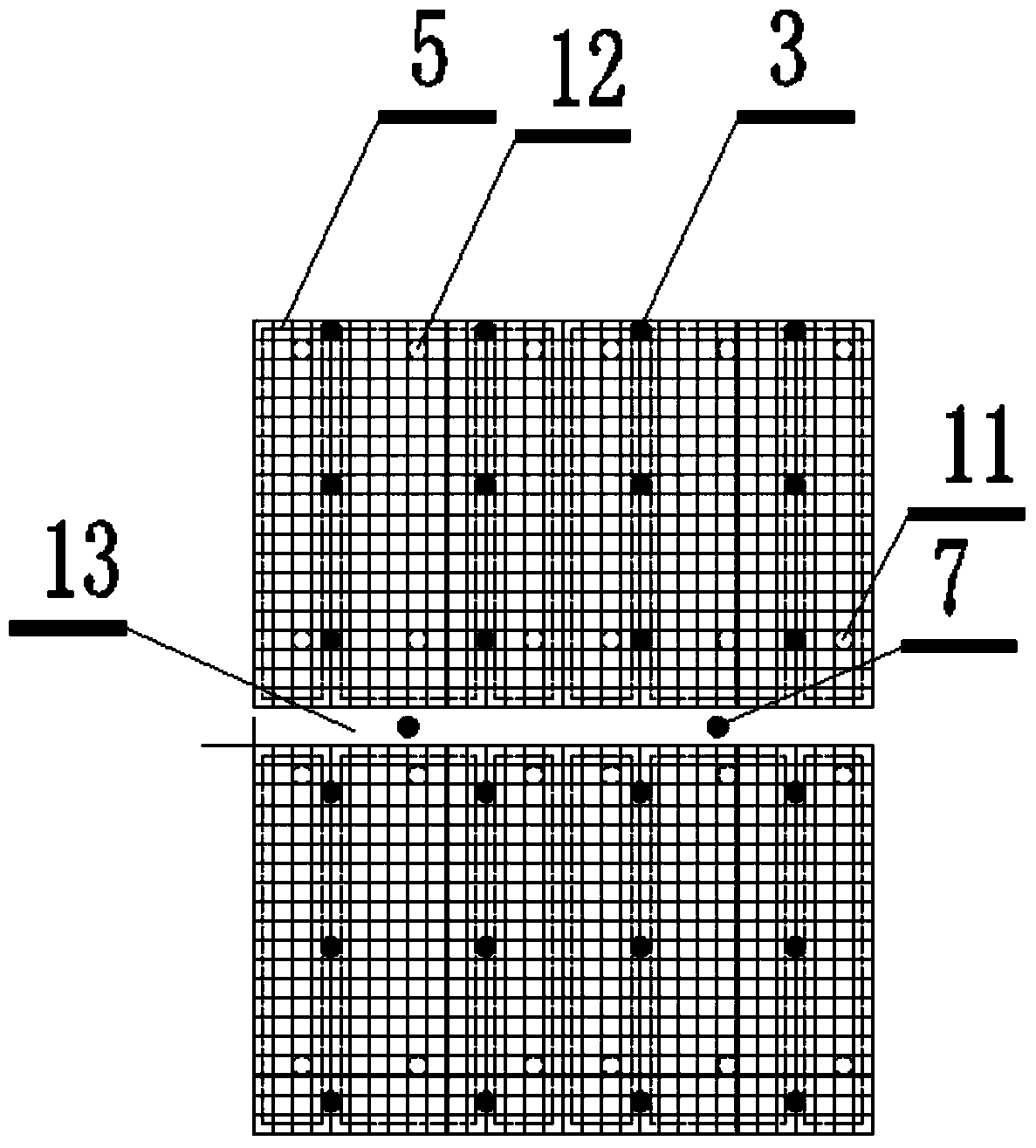

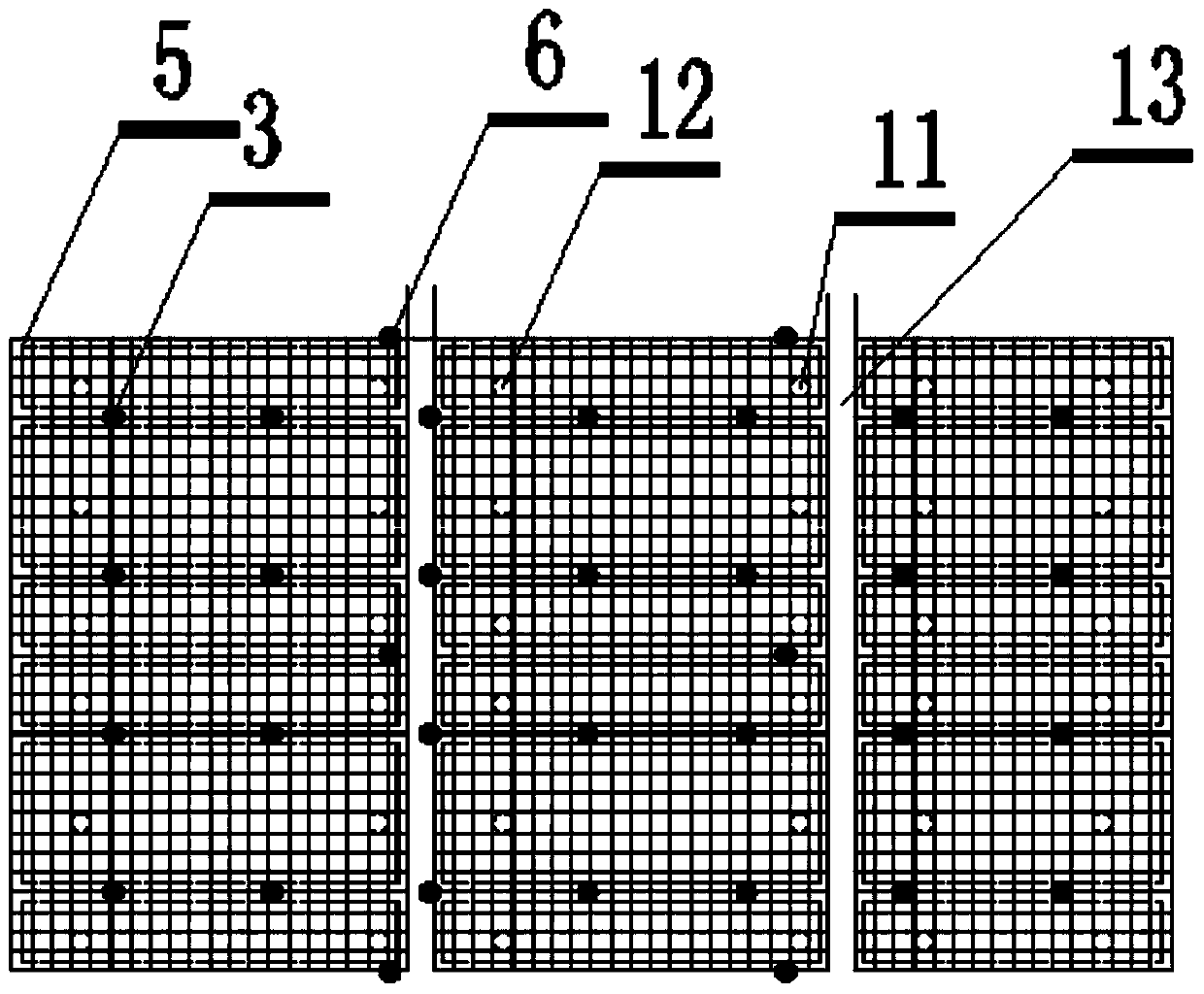

[0029] Figure 1-4 As shown, the structural schematic diagram of a weak cemented formation roadway support system of the present invention is mainly to solve the roadway stability problems of weak cemented formation rocks in western mining areas with low strength, poor cementation, and water-disintegrating rock formations, such as The underground coal roadway of a certain mine is buried in depth of 675m, located to the north of the underground car yard. The roadway is located in the 3-1 coal seam of the Jurassic Yan'an Formation. The roof is sandy mudstone and the thickness of the coal seam is 6.5m. The roadway is driven along the roof of the coal seam. The uniaxial compressive strength of rock and coal is between 20-30MPa, which is a typical weak cemented rock formation. The section of the roadway is rectangular, and the original support adopts anch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com