A dynamic control method for preventing non-uniform roof settlement of roadway cut without coal pillars

A coal pillar-free, non-uniform technology, applied in the direction of earth drilling, ground mining, mining equipment, etc., can solve problems such as subsidence, affecting ventilation, pedestrians, and compression of the cross-sectional area of the roadway, so as to improve the stress state and secure the anchor point , Limit the effect of deformation and damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

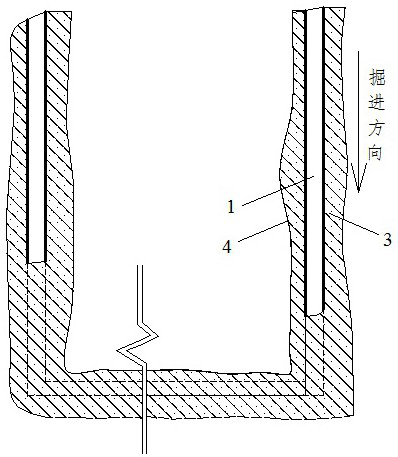

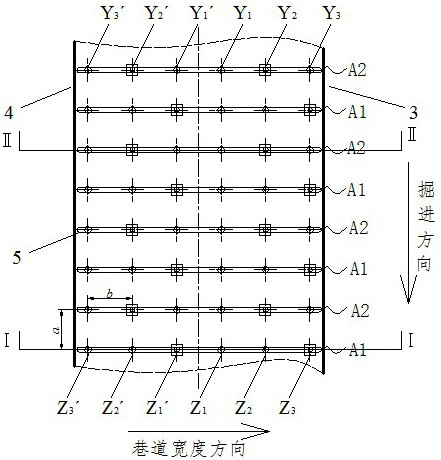

[0056] like Figure 1-5 As shown, step 1) arrange the first anchor cable system A1 and the second anchor cable system A2 along the roadway direction during the excavation, and the distance between the two systems is a;

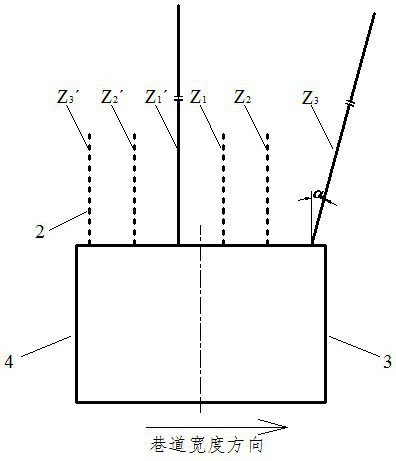

[0057] like figure 1 , 2 As shown in and 3, step 1) arranging the first bolt system A1, the steps are as follows: step 1.1) according to the coal seam roof and floor 2 conditions, the roadway width l and the bolt cable parameter type, determine different bolt cable combination schemes based on theoretical calculation formulas , so that the bearing capacity of the roof after support shall not be less than 0.5MPa, the calculation formula is as follows:

[0058]

[0059] In the formula, σ is the bearing capacity of the roof after support, Q is the pre-tightening force of the anchor rod or anchor cable, l 0 is the effective length of the anchor rod or anchor cable; α is the control angle of the anchor rod or anchor cable, s 0 is the anchor rod or anchor cab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com