Detection method for leakage of buried metal pipeline

A detection method and pipeline technology, applied in pipeline systems, mechanical equipment, gas/liquid distribution and storage, etc., can solve problems such as high false alarm rate, difficulty in realizing online real-time diagnosis, incomplete diagnosis information, etc., and achieve accurate leakage Detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

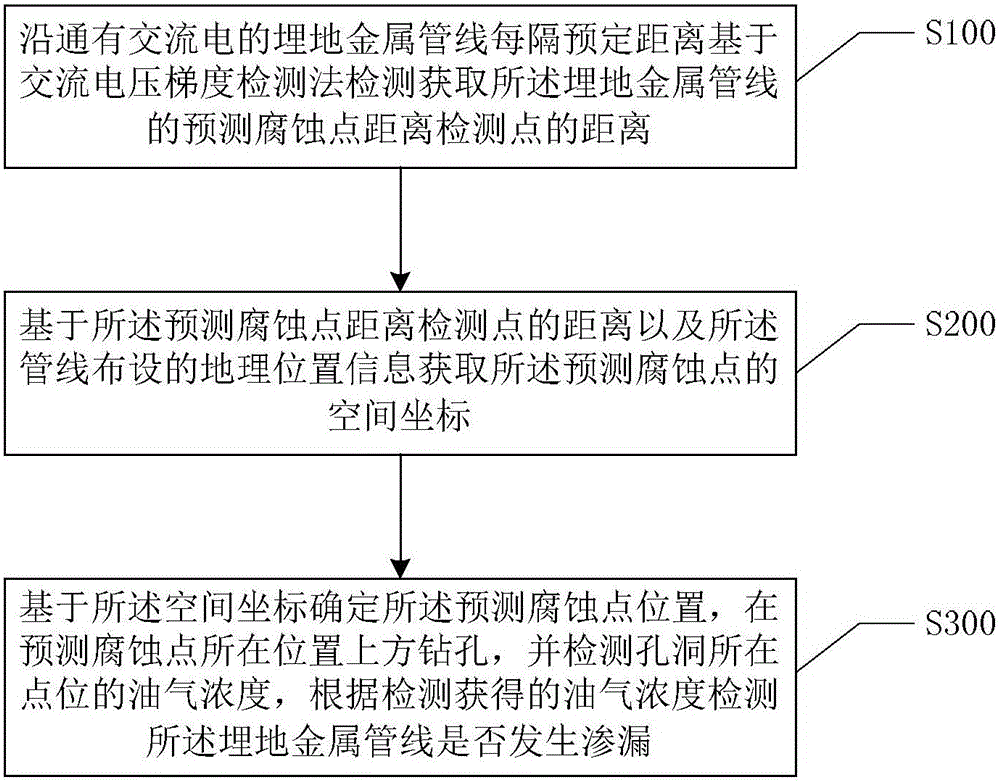

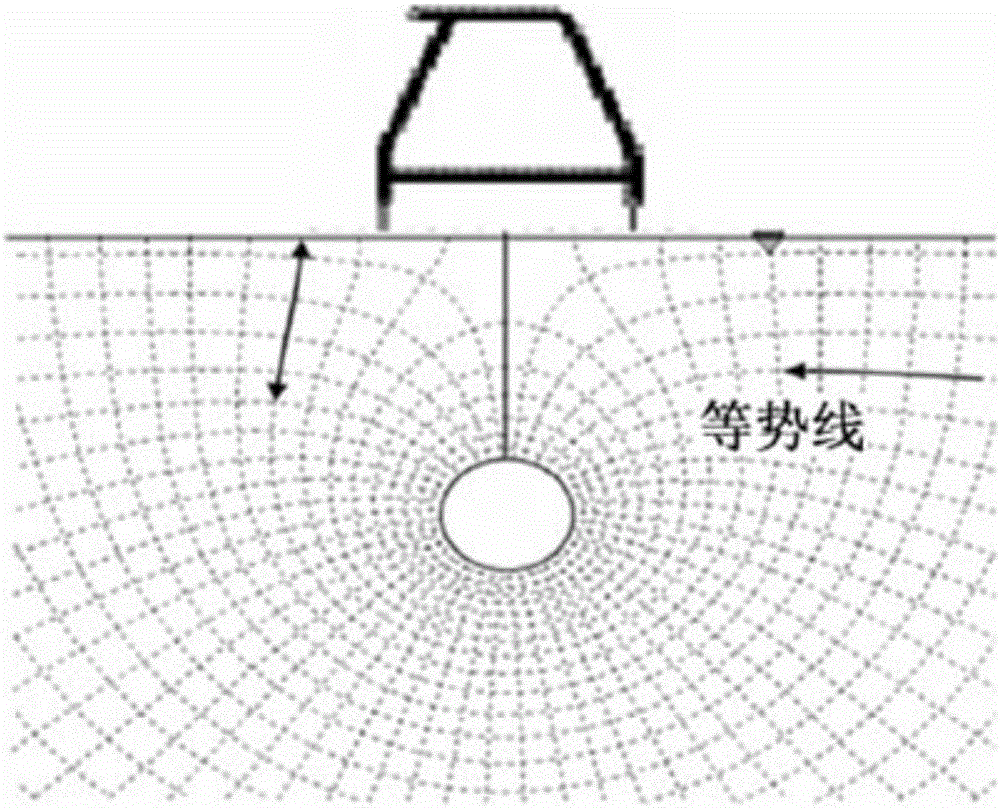

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described below based on examples, but the present invention is not limited to these examples. In the following detailed description of the present invention, some specific details are described in detail. Those skilled in the art can fully understand the present invention without the description of these details. In order to avoid obscuring the essence of the present invention, well-known methods, processes, procedures, components and circuits are not described in detail.

[0028] In addition, those of ordinary skill in the art should understand that the drawings provided herein are for illustrative purposes, and the drawings are not necessarily drawn to scale.

[0029] Unless the context clearly requires, the words "including", "including" and other similar words in the entire specification and claims should be interpreted as inclusive rather than exclusive or exhaustive meanings; in other words, "including but not limited to" Meaning.

[0030] In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com