Noncontact wheel multifunctional detection system

A detection system and multi-functional technology, applied in the direction of measuring devices, instruments, and optical devices, can solve the problems of slow test speed, low test efficiency, and difficulty in online detection, so as to improve test speed, facilitate data traceability, and facilitate The effect of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

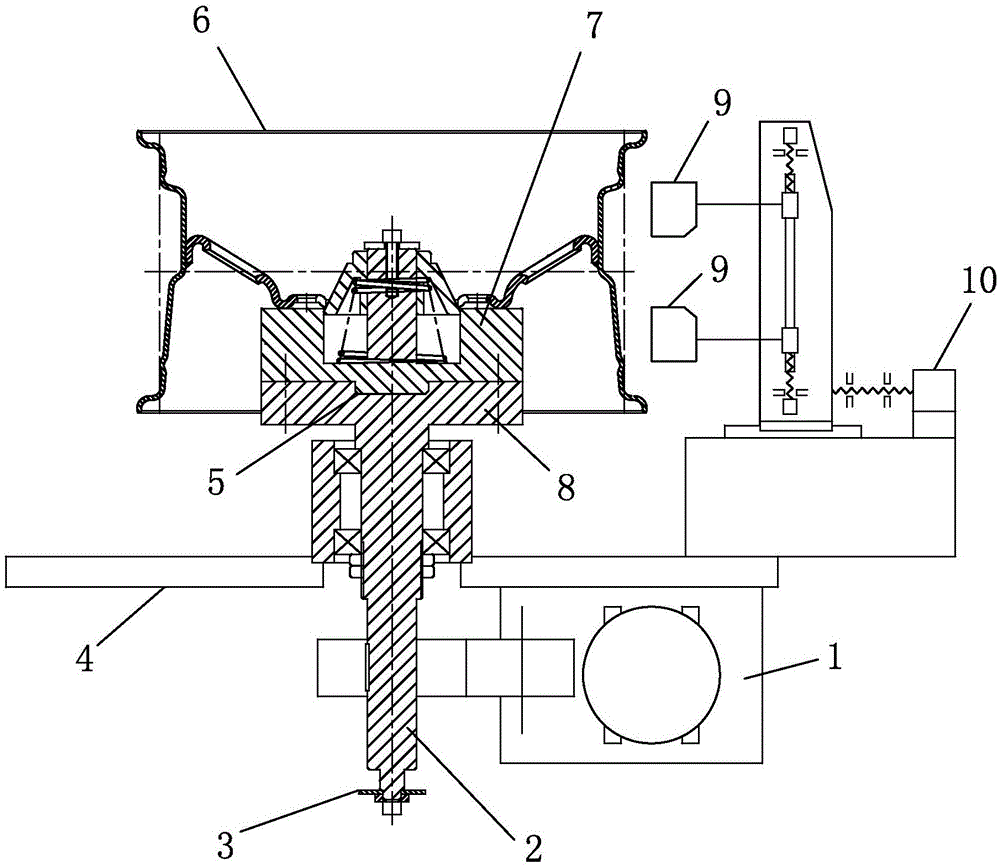

[0023] Embodiment: the non-contact wheel multifunctional detection system of the present invention, as attached figure 1 , attached figure 2 As shown, it includes a control system, a detection system, a data processing system, a shaft driving device 1 and a rotating shaft 2 driven by the shaft driving device 1. The rotating shaft 2 is sleeved with two tapered roller bearings, and the outer rings of the two tapered roller bearings are sleeved with bearings. The bearing seat is fixedly connected to the test bench body 4.

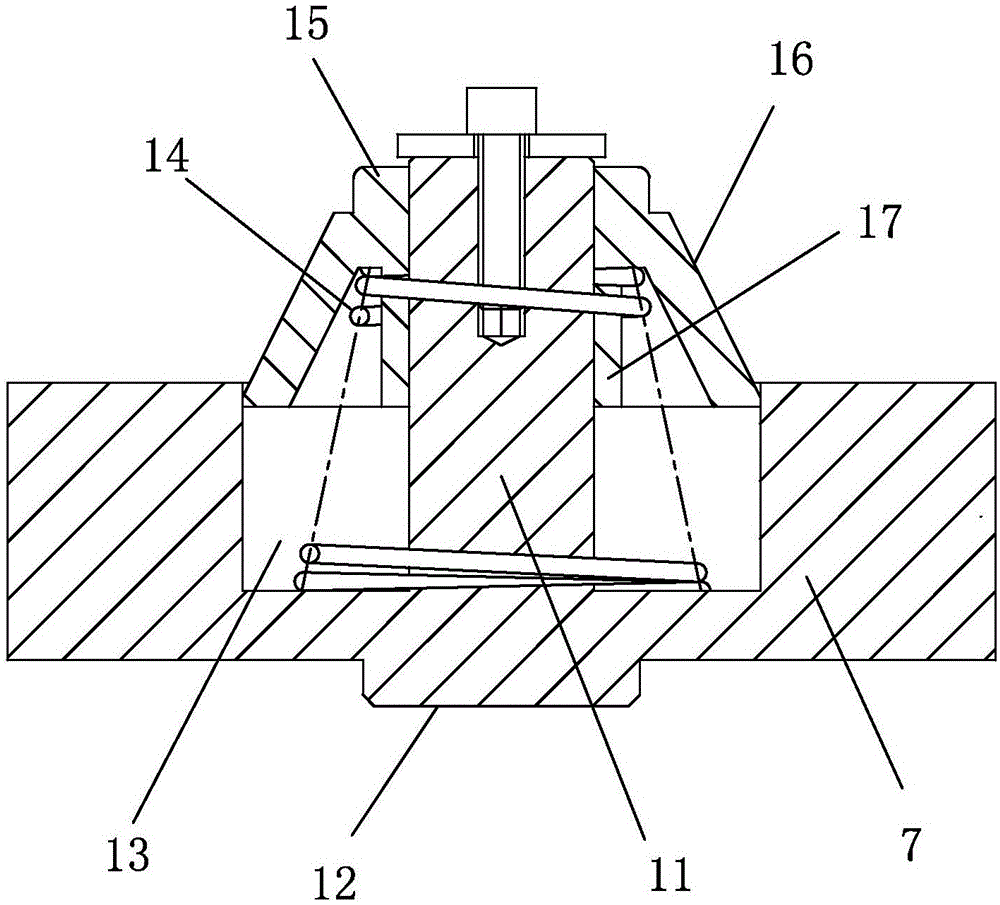

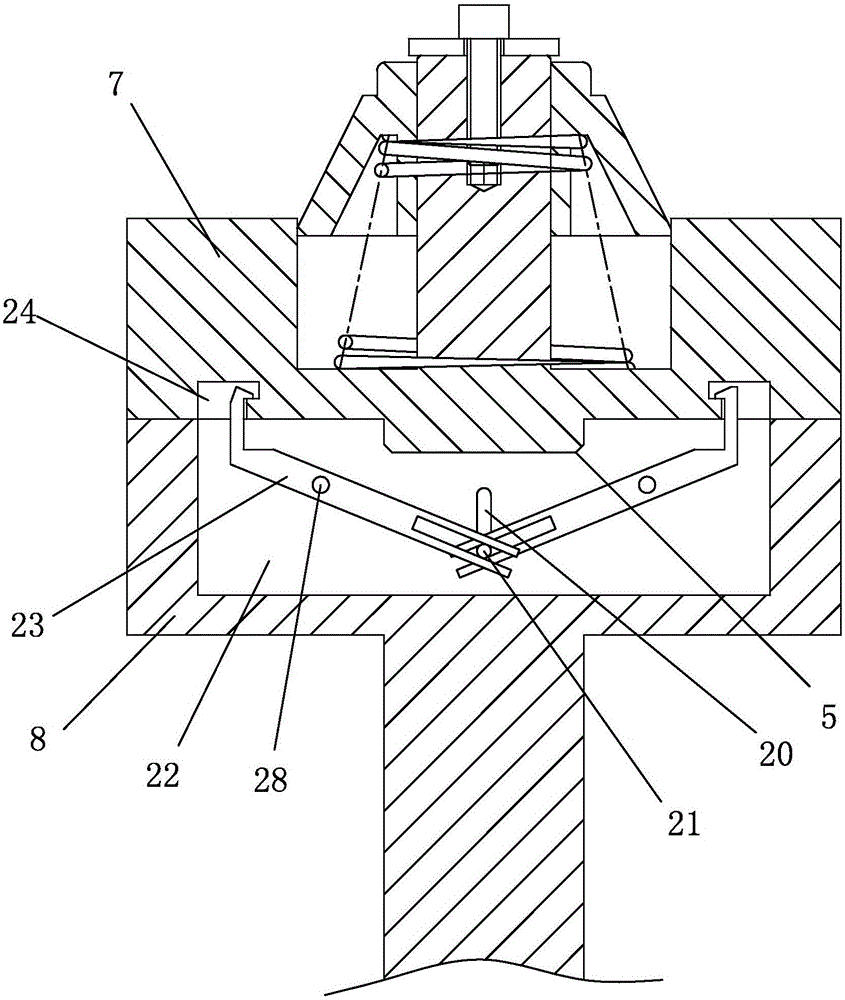

[0024] Rotating shaft 2 is arranged vertically, and round table 8 is arranged on the top, and test bench 7 is connected on the round table 8; There is a column 11 in the middle, and the column 11 is covered with a conical platform 15 that slides up and down along the column 11. The conical platform 15, the column 11 and the rotating shaft 2 are coaxially arranged; the diameter of the top of the conical platform 15 is smaller than the center hole of the wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com