Photovoltaic backboard chloride ion permeability testing method and device

A photovoltaic backplane and testing device technology, which is applied in measurement devices, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problems of internal grid line corrosion, photovoltaic module power generation efficiency attenuation, poor water vapor barrier, etc. problem, to achieve the effect of convenient operation, cheap price and simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

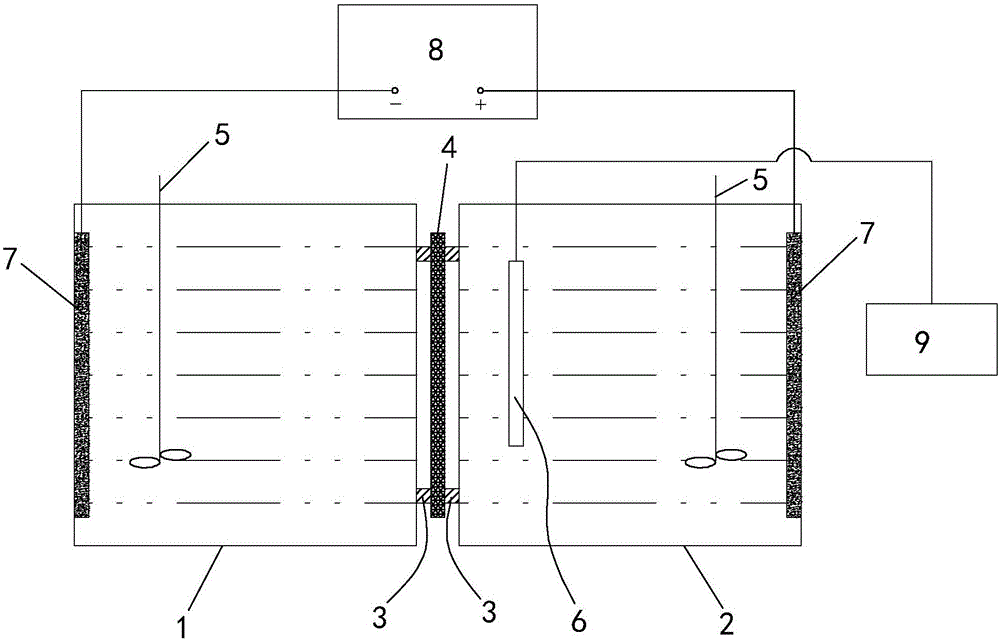

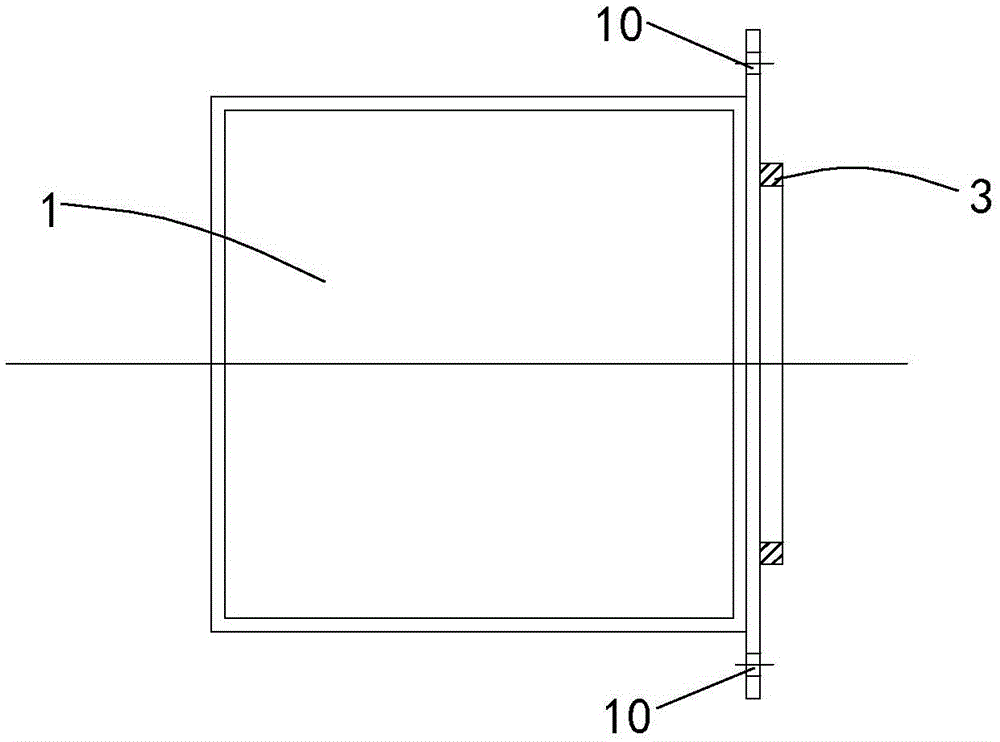

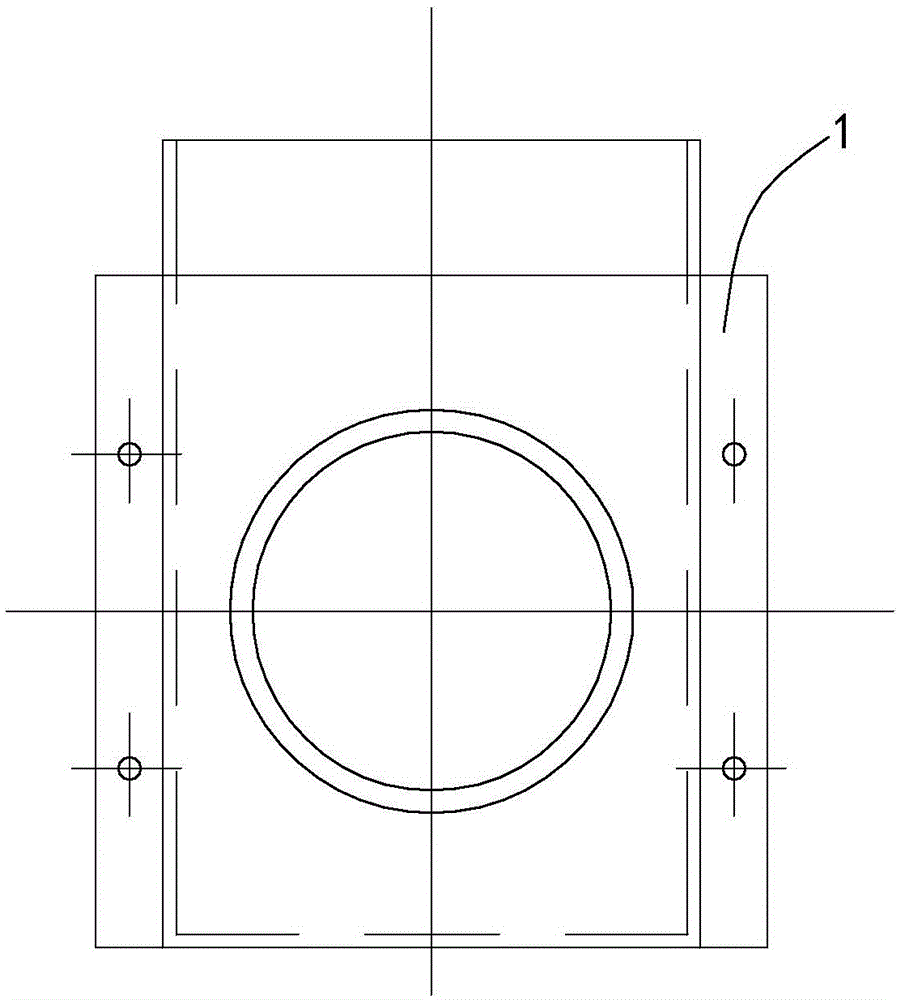

[0051] Such as Figure 1 to Figure 5 The shown photovoltaic backplane chloride ion permeability testing device includes a permeation cell 1, a permeation cell 2, a conductivity electrode 6, two graphite electrodes 7, and a conductivity meter 9. The permeation cell 1 and The permeation tanks 2 all have a top cover, wherein the permeation tank 1 has a permeation tank cover plate 11, and the permeation tank 2 has a permeation tank cover plate 12. The permeation tank 1 and permeation tank 2 There are rehydration ports on the top cover. Sodium chloride solution or deionized water can be added to the pool through the refill port to supplement the solution loss during the test. The permeation cell 1 is filled with high-concentration chlorine with a concentration of 30g / L. Sodium chloride solution, the permeation tank 2 is filled with a low-concentration sodium chloride solution with a concentration of 0.1mg / L, the permeation tank 1 and the permeation tank 2 are both equipped with an ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com