A kind of photothermal power generation composite material backplane and preparation method

A composite material and photothermal power generation technology, which is applied in solar thermal power generation, lighting and heating equipment, optics, etc., can solve the problems of time-consuming and laborious on-site concentration adjustment, poor temperature and weather resistance of steel plates, and unfavorable mass production. Achieve the effects of low cost, improved service life and convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

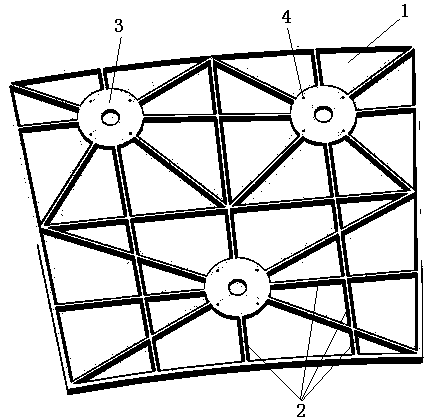

[0029] Such as figure 1 with 2 As shown, a photothermal power generation composite material backplane includes a backplane 1 and a reflective mirror laid on one side of the backplane. The other side of the backplane 1 is provided with a plurality of ribs 2 and a plurality of connecting discs. 3. The ribs 2 extend from the edge of the connecting disc 3 to the edge of the back plate 1 . A plurality of nuts 4 are arranged on the connecting disk 3 . The backplane 1 and the connection disc 3 are made of epoxy resin. Further, a reinforcing layer is arranged inside the backboard. Further, the reinforcement layer includes chopped strand mat, square cloth, triaxial cloth, and PVC sandwich foam laid sequentially from the outside to the inside. The setting of the reinforcement layer can enhance the strength of the composite material backplane, and protect the backplane structure from being damaged by particles such as external sand and gravel. Further preferably, the reinforcing ri...

Embodiment 2

[0035] Such as figure 1 with 2As shown, a photothermal power generation composite material backplane includes a backplane 1 and a reflective mirror laid on one side of the backplane. The other side of the backplane 1 is provided with a plurality of ribs 2 and a plurality of connecting discs. 3. The ribs 2 extend from the edge of the connecting disc 3 to the edge of the back plate 1 . A plurality of nuts 4 are arranged on the connecting disc 3 . The backplane 1 and the connection disc 3 are made of epoxy resin. Further, a reinforcing layer is arranged inside the backboard. Further, the reinforcement layer includes chopped strand mat, square cloth, triaxial cloth, and PVC sandwich foam laid sequentially from the outside to the inside. The setting of the reinforcement layer can enhance the strength of the composite material backplane, and protect the backplane structure from being damaged by particles such as external sand and gravel. Further preferably, the reinforcing rib...

Embodiment 3

[0041] Such as figure 1 with 2 As shown, a photothermal power generation composite material backplane includes a backplane 1 and a reflective mirror laid on one side of the backplane. The other side of the backplane 1 is provided with a plurality of ribs 2 and a plurality of connecting discs. 3. The ribs 2 extend from the edge of the connecting disc 3 to the edge of the back plate 1 . A plurality of nuts 4 are arranged on the connecting disc 3 . The backplane 1 and the connection disc 3 are made of epoxy resin. Further, a reinforcing layer is arranged inside the backboard. Further, the reinforcement layer includes chopped strand mat, square cloth, triaxial cloth, and PVC sandwich foam laid sequentially from the outside to the inside. The setting of the reinforcement layer can enhance the strength of the composite material backplane, and protect the backplane structure from being damaged by particles such as external sand and gravel. Further preferably, the reinforcing ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com