Tunable capturing and screening method of linear polarization planar optical waves for liquid crystal material particle above substrate

A technology of liquid crystal material and plane light wave, which is applied in the fields of medicine, nanomanipulation and biology, can solve problems such as difficult to capture, complex incident light source, non-tunable gradient optical force, etc., and achieve the effect of convenient operation and simple system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

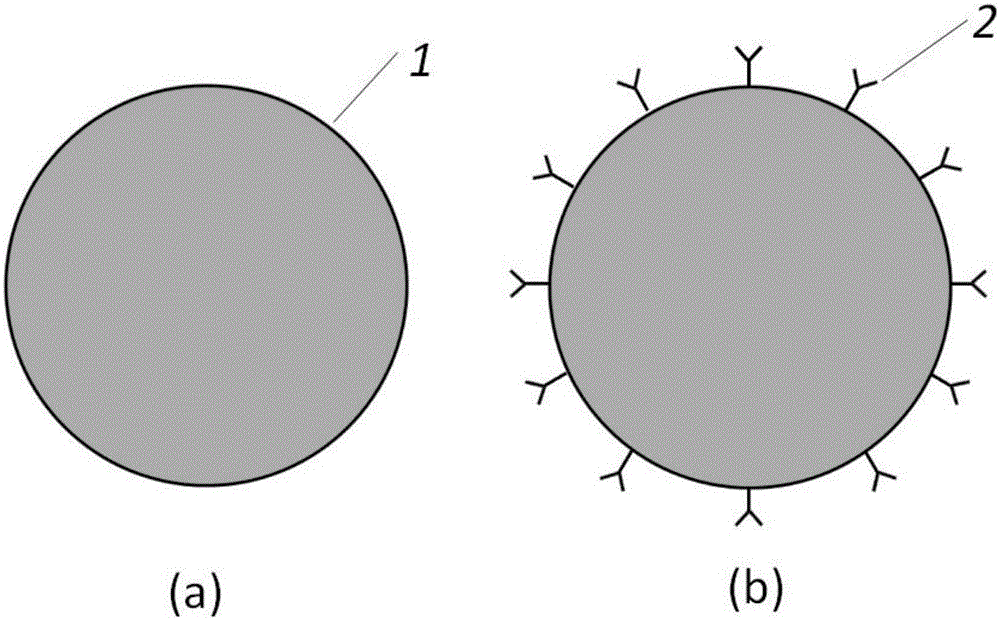

[0021] First, the liquid crystal material particles 1 are produced through the material growth process, as shown in the attached figure 1 (a) shown. The geometric shape and size of the liquid crystal material particles can be determined by algorithms such as finite time domain difference method and finite element method.

[0022] Secondly, nano-sized molecules 2 are attached to the outer surface of the liquid crystal material particles 1, such as attached figure 1 (b) shown.

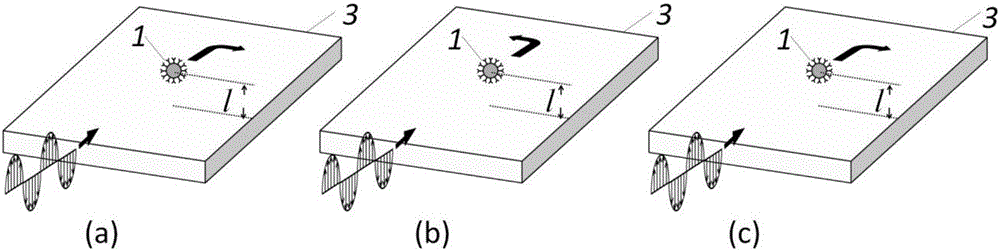

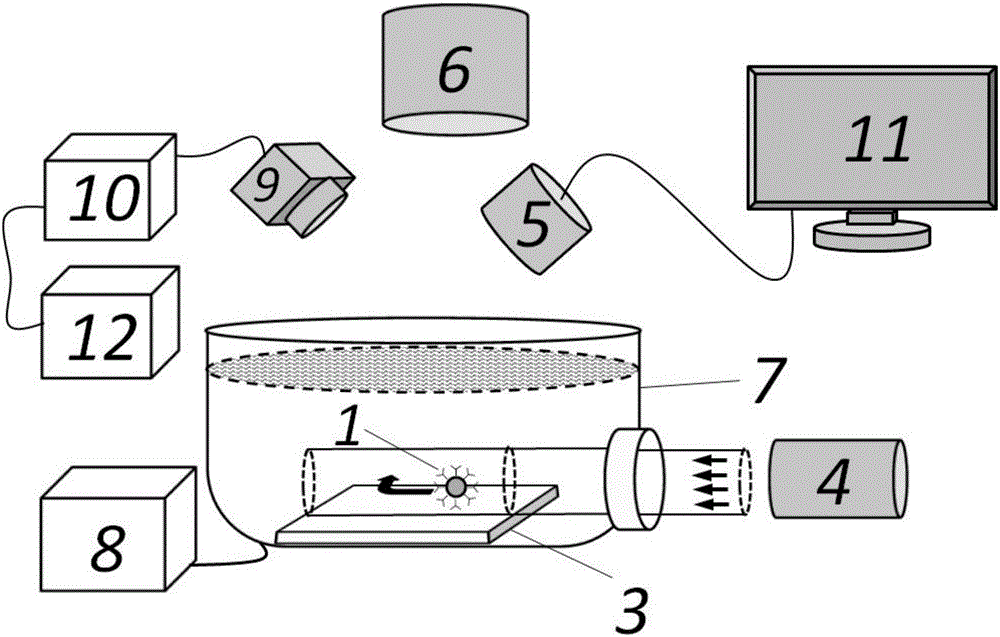

[0023] Then, place the liquid crystal material particles 1 with nanometer-sized molecules 2 attached on the surface above the substrate plate 3 at a distance of l (l>0), when the incident light is a linearly polarized plane wave and the liquid crystal molecular axis and the optical axis When the directions are the same, the Poynting vectors around the liquid crystal material particles 1 above the substrate 3 are distributed asymmetrically, that is, the total Poynting vectors on the liquid crystal mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com