Prediction method of main beam deflection deformation based on uneven shrinkage effect of section

A technology of uniform shrinkage and flexural deformation, applied in special data processing applications, instruments, calculations, etc., can solve problems such as difficulty in considering the effect of uneven shrinkage of box girder sections, and no clear implementation method for finite element prediction and analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

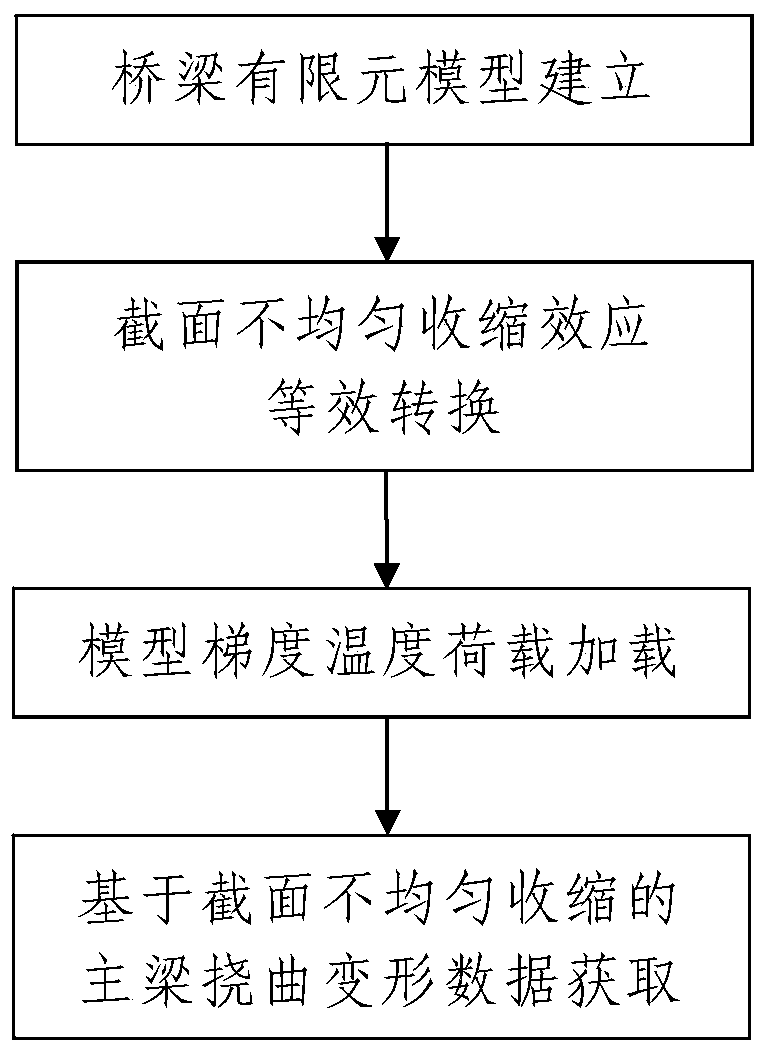

[0060] like figure 1 A method for predicting the deflection deformation of the main beam based on the effect of uneven shrinkage of the section shown includes the following steps:

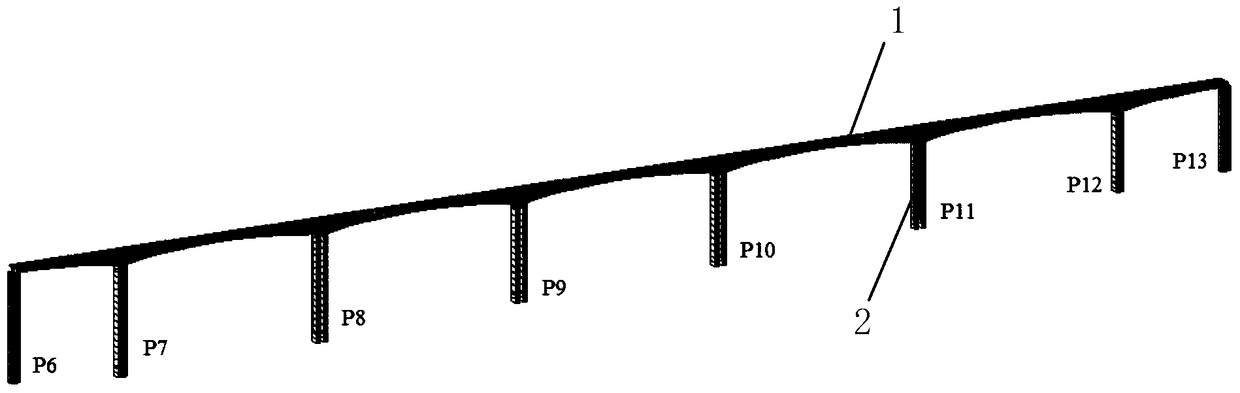

[0061] Step 1. Building the finite element model of the bridge: using data processing equipment and finite element analysis software to establish a simulation model of the spatial structure of the main girder 1 to be analyzed.

[0062]The main beam 1 to be analyzed is a prestressed concrete box girder (i.e. PC box girder) and it is a variable-section beam, and the main beam 1 to be analyzed is divided into N beam units 1- 1. Wherein, N is a positive integer and N≥10.

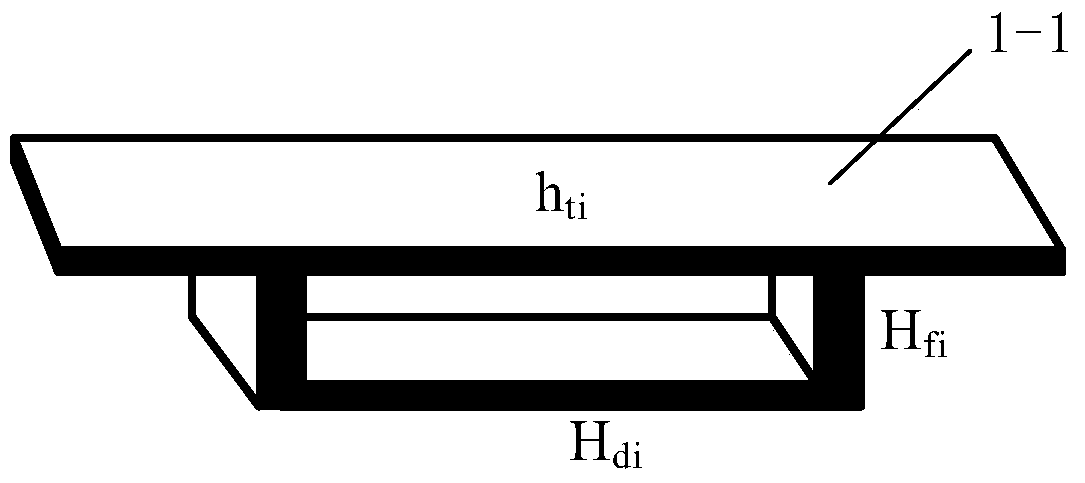

[0063] Step 2. Equivalent transformation of section uneven shrinkage effect: perform equivalent transformation on the section uneven shrinkage effect of each beam unit 1-1 in the main beam 1 to be analyzed at time t, and obtain the corresponding equivalent of each beam unit 1-1 Gradient temperature; where, t time is the age of con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com