A battery pack module

A battery and grouping technology, which is applied in the direction of battery pack parts, batteries, circuits, etc., can solve the problems of lack of tab positioning devices, etc., and achieve the effect of improving the overall assembly quality, light weight, and increasing volume specific energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

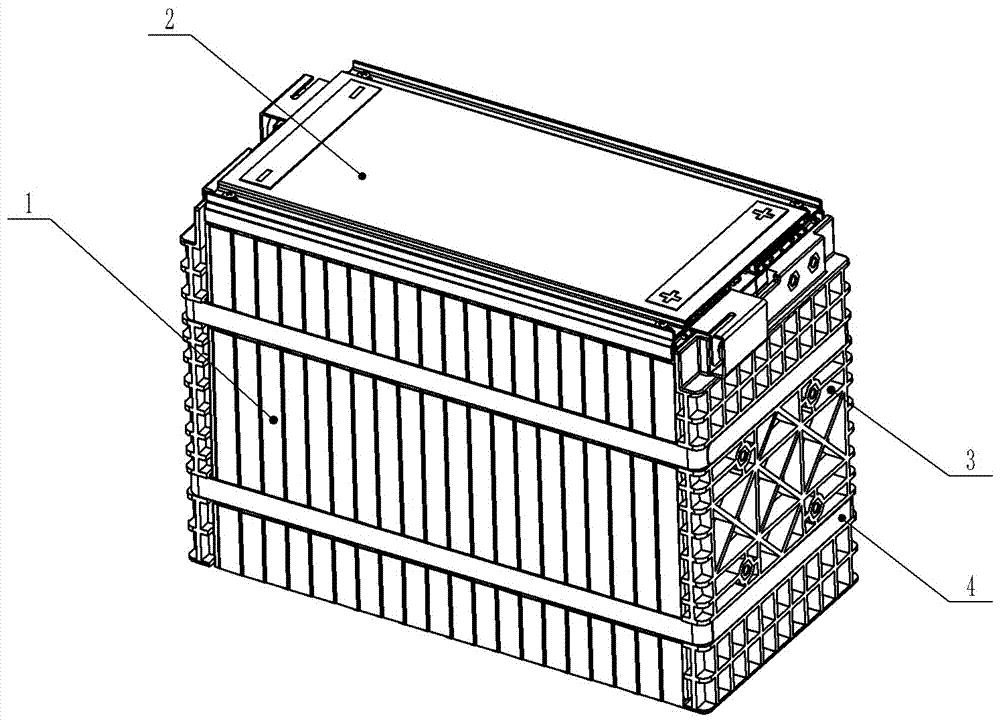

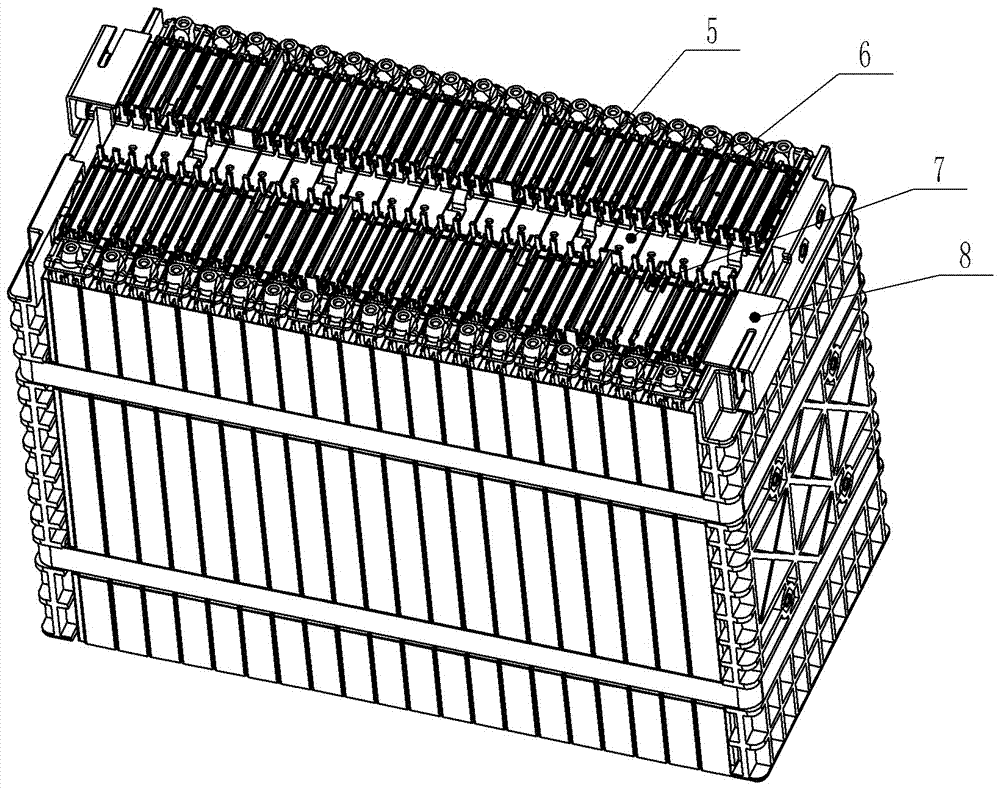

[0043] Such as Figure 1 to Figure 19 As shown, an embodiment of a battery grouping module, the battery grouping module in this embodiment includes a battery unit 1, a cover plate 2, a binding baffle 3, a binding band 4, a conductive bar 5, an insulating grid assembly 6, a wiring Terminal 7 and insulating end cap 8.

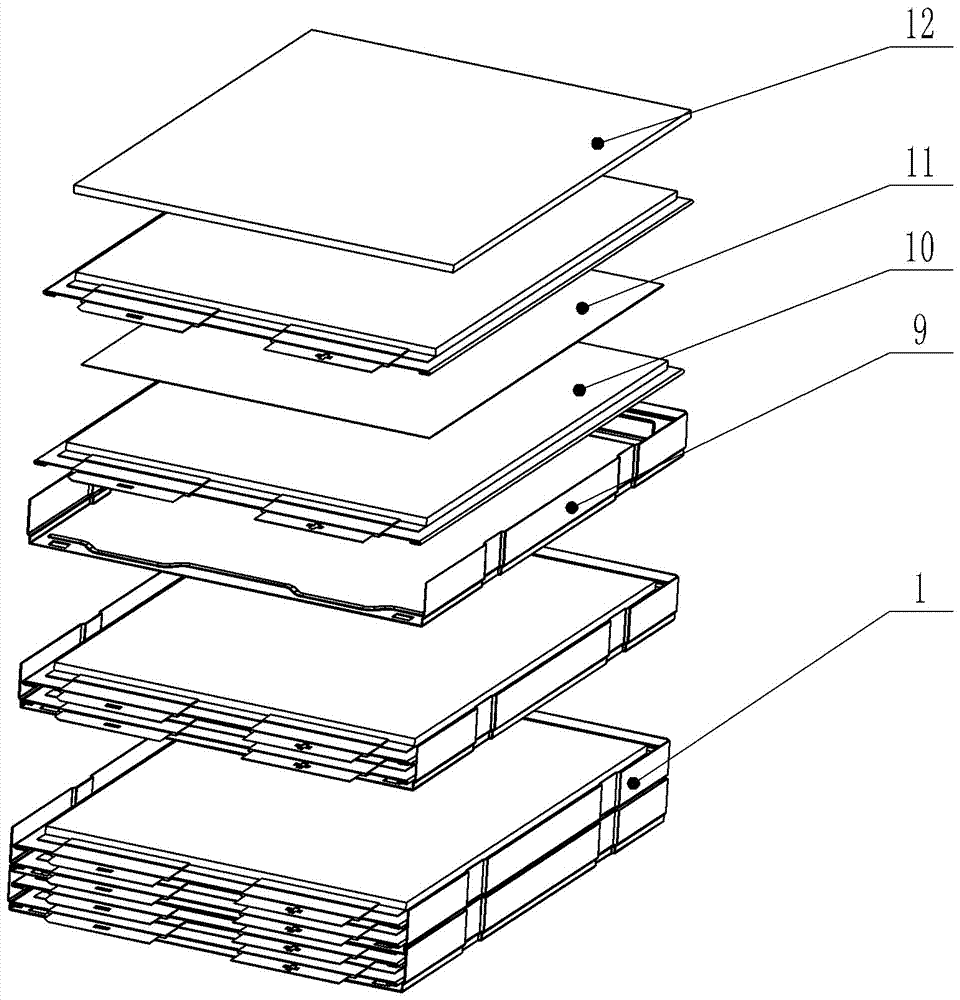

[0044] A plurality of battery units 1 are arranged in sequence along the left and right directions. Each battery unit 1 includes a heat dissipation protection plate 9 and a battery 10 fixed in the heat dissipation protection plate 9 . Each battery 10 has a positive tab and a negative tab respectively. According to the number of batteries contained in the battery unit, the battery unit can be divided into a single battery unit and a multi-battery unit. The heat dissipation protection plate of the single battery unit accommodates a single battery, and the heat dissipation protection plate of the multi-battery unit in this embodiment Contains two batteries. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com