A temperature-controlled metal casting device

A technology of metal casting and material holding device, which is applied in the field of metal casting, can solve the problems of uneven grain size, high energy consumption, and non-dense internal structure of castings, and achieves high production efficiency, uniform grain size, and compact internal structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

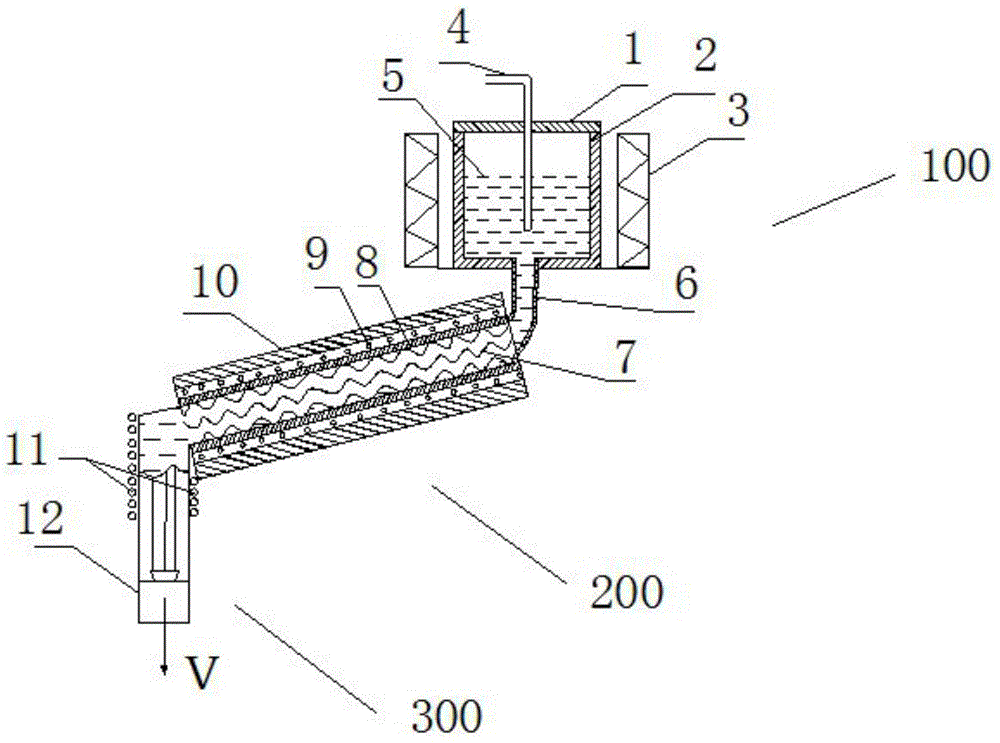

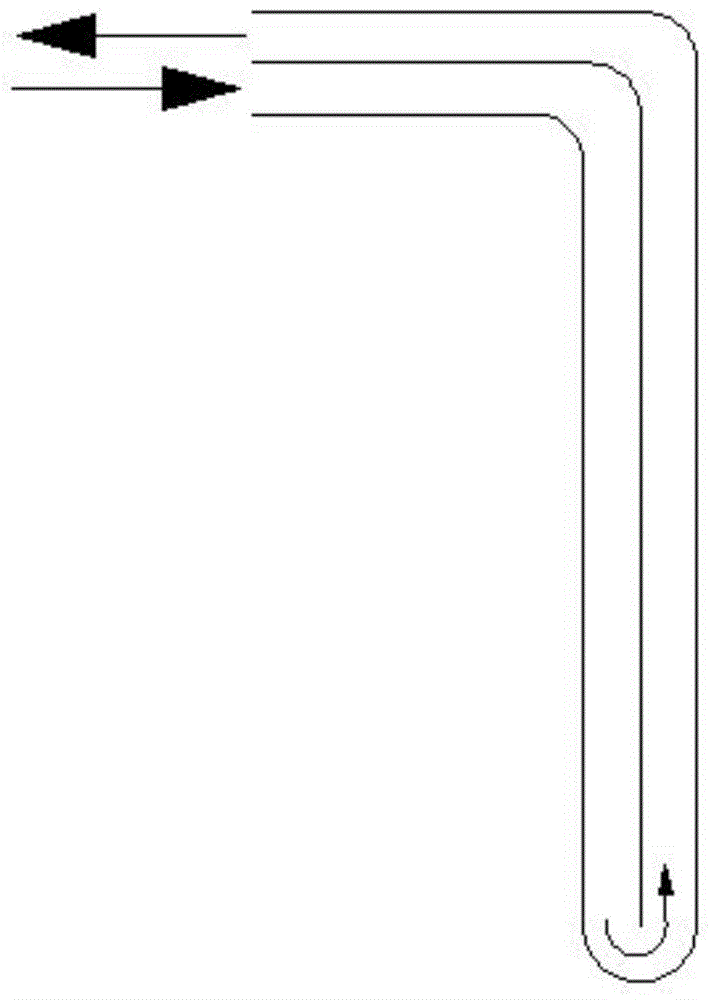

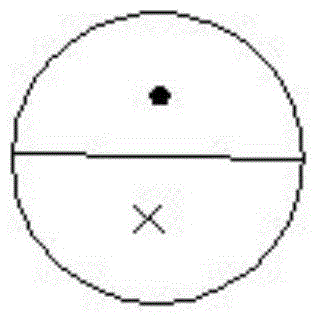

[0036] like figure 1 As shown, a temperature-controlled metal casting device includes a material holding device 100, a homogenizing device 200, and a stretching device 300; wherein, the material holding device 100 includes a crucible 1, a crucible top cover 2, an electromagnetic stirrer 3, a flow guide Pipe 6; Homogenizing device 200 includes helical pipe 7, inner insulation layer 8, cooling pipe 9, outer insulation layer 10; stretching device 200 includes heating device 11 and traction mechanism 12; around. In addition, the connection relationship between the material holding device 100 , the homogenizing device 200 and the stretching device 300 is as follows: the upper end of the homogenizing device 200 is connected to the guide pipe 6 below the material holding device 100 , and the stretching device 300 is connected to the lower end of the homogenizing device 200 .

[0037] The material holding device 100 of the above temperature-controlled metal casting device may furthe...

Embodiment 2

[0042] refer to figure 1 , a temperature-controlled metal casting device, comprising a material holding device 100, a homogenizing device 200, and a stretching device 300; wherein, the material holding device 100 includes a crucible 1, a crucible top cover 2, an electromagnetic stirrer 3, and a guide tube 6 ; Homogenizing device 200 includes spiral pipeline 7, internal insulation layer 8, cooling pipeline 9, external insulation layer 10; stretching device 200 includes heating device 11 and traction mechanism 12; electromagnetic stirrer 3 wraps around the material holding device. In addition, the connection relationship between the material holding device 100 , the homogenizing device 200 and the stretching device 300 is as follows: the upper end of the homogenizing device 200 is connected to the guide pipe 6 below the material holding device 100 , and the stretching device 300 is connected to the lower end of the homogenizing device 200 . The material holding device 100 of th...

Embodiment 3

[0047] refer to figure 1 , a temperature-controlled metal casting device, comprising a material holding device 100, a homogenizing device 200, and a stretching device 300; wherein, the material holding device 100 includes a crucible 1, a crucible top cover 2, an electromagnetic stirrer 3, and a guide tube 6 ; Homogenizing device 200 includes spiral pipeline 7, internal insulation layer 8, cooling pipeline 9, external insulation layer 10; stretching device 200 includes heating device 11 and traction mechanism 12; electromagnetic stirrer 3 wraps around the material holding device. In addition, the connection relationship between the material holding device 100 , the homogenizing device 200 and the stretching device 300 is as follows: the upper end of the homogenizing device 200 is connected to the guide pipe 6 below the material holding device 100 , and the stretching device 300 is connected to the lower end of the homogenizing device 200 . The material holding device 100 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com