Composite liner plate and mounting method thereof

A technology of composite lining board and installation method, applied in chemical instruments and methods, rubber layered products, layered products, etc., can solve the problems of complex process, increase the weight and cost of lining board, etc., and achieve low comprehensive cost and easy installation. and replacement, adaptable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

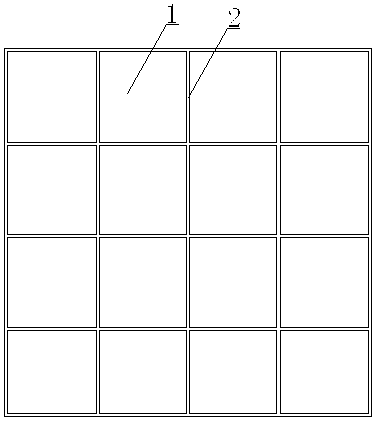

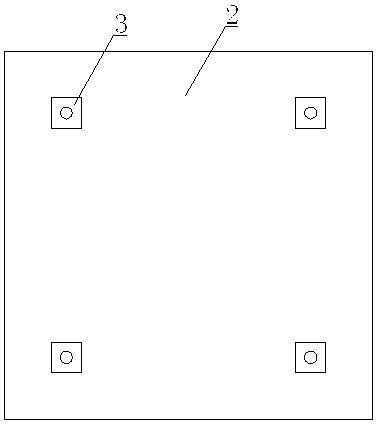

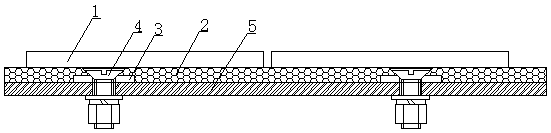

[0026] Such as Figure 1 to Figure 3 The composite liner shown includes a foamed rubber layer 2 with a thickness of 10 mm, several glass-ceramic panels 1 with a length of 200-300 mm, a width of 150-250 mm, and a thickness of 10 mm bonded to the surface of the foamed rubber layer 2 Above, there is a gap of 5-10 mm between two adjacent glass-ceramic panels 1, and four steel plates 3 with a length of 100 mm, a width of 100 mm, and a thickness of 5 mm are embedded in the foam rubber layer 2 and vulcanized with the foam rubber. Together, the steel plate 3 and the foam rubber layer 2 are provided with through holes for installing countersunk bolts 4 .

[0027] The installation process of the composite liner includes the following steps: on the mother board 5 to be protected, a bolt hole corresponding to the through hole of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com