Reflecting luminous film

A luminescent film and reflective technology, which is applied in the direction of synthetic resin layered products, layered products, chemical instruments and methods, etc., can solve the problems of unsatisfactory effects, mutual interference of luminous and reflective light, etc., to improve the heat insulation effect, Effect of reducing radiation and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

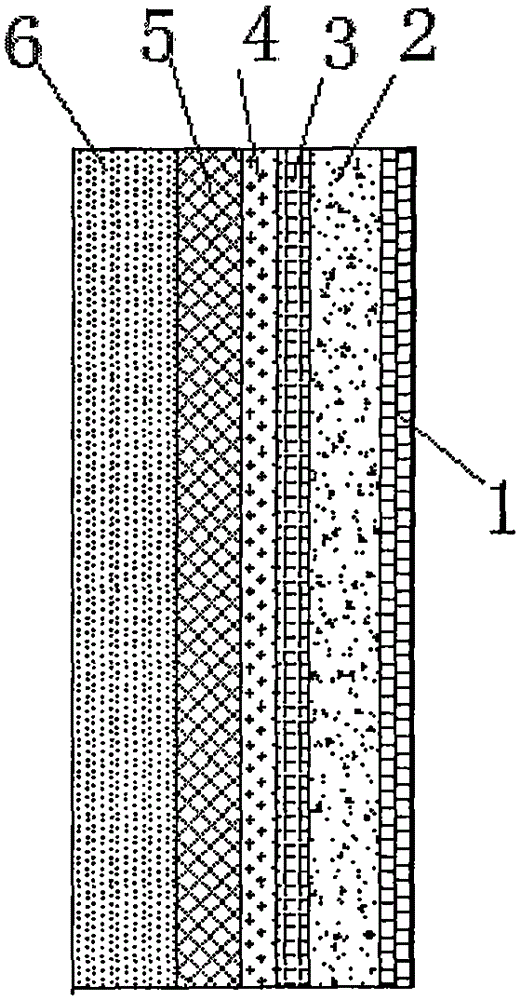

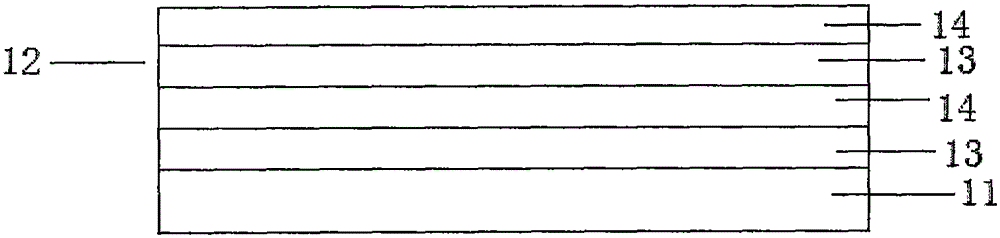

[0031] A reflective light-emitting film, which includes an explosion-proof film 1, a reflective layer 2, a light-emitting layer 3, a hardness treatment layer 4, a three-dimensional embossed layer 5, and a base layer 6 connected by an adhesive from top to bottom. The explosion-proof film 1 includes a base 11 and a design The color-changing layer 12 on the substrate 11, the color-changing layer 12 is formed by staggered arrangement of sulfide nano-layers 13 and oxide nano-layers 14, and the base layer 6 is prepared from the following components by weight:

[0032] 30 parts of polycarbonate; 5 parts of silicon-containing polycarbonate resin; 0.5 parts of chemical resistance modifier, 5 parts of heat resistance agent; 3 parts of flame retardant synergist; 6 parts of brominated flame retardant, 0.1 part of antioxidant 1 part, 0.1 part of lubricant, 1 part of inorganic nanoparticles, 1 part of vanillin and 1 part of thymol;

[0033] The luminescent layer 3 is prepared from the follo...

Embodiment 2

[0036] A reflective light-emitting film, which includes an explosion-proof film 1, a reflective layer 2, a light-emitting layer 3, a hardness treatment layer 4, a three-dimensional embossed layer 5, and a base layer 6 connected by an adhesive from top to bottom. The explosion-proof film 1 includes a base 11 and a design The color-changing layer 12 on the substrate 11, the color-changing layer 12 is formed by staggered arrangement of sulfide nano-layers 13 and oxide nano-layers 14, and the base layer 6 is prepared from the following components by weight:

[0037] 50 parts of polycarbonate; 15 parts of silicon-containing polycarbonate resin; 5 parts of chemical resistance modifier, 25 parts of heat resistance agent; 6 parts of flame retardant synergist; 22 parts of brominated flame retardant, 1 part of antioxidant 1 part, 1 part of lubricant, 10 parts of inorganic nanoparticles, 2 parts of vanillin and 2 parts of thymol;

[0038] The luminescent layer 3 is prepared from the foll...

Embodiment 3

[0041]A reflective light-emitting film, which includes an explosion-proof film 1, a reflective layer 2, a light-emitting layer 3, a hardness treatment layer 4, a three-dimensional embossed layer 5, and a base layer 6 connected by an adhesive from top to bottom. The explosion-proof film 1 includes a base 11 and a design The color-changing layer 12 on the substrate 11, the color-changing layer 12 is formed by staggered arrangement of sulfide nano-layers 13 and oxide nano-layers 14, and the base layer 6 is prepared from the following components by weight:

[0042] 40 parts of polycarbonate; 10 parts of silicon-containing polycarbonate resin; 2.75 parts of chemical resistance modifier, 15 parts of heat resistance agent; 4.5 parts of flame retardant synergist; 14 parts of brominated flame retardant, 0.55 parts of antioxidant 0.55 parts of lubricant, 5.5 parts of inorganic nanoparticles, 1.5 parts of vanillin and 1.5 parts of thymol;

[0043] The luminescent layer 3 is prepared from...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com