Activity selectivity modulating method of Ru-Zn catalyst for cyclohexene production through benzene selective hydrogenation

A technology for selective hydrogenation and catalyst, applied in the field of chemical industry, can solve problems such as dependence on imports, and achieve the effect of low cost and good modulation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~5

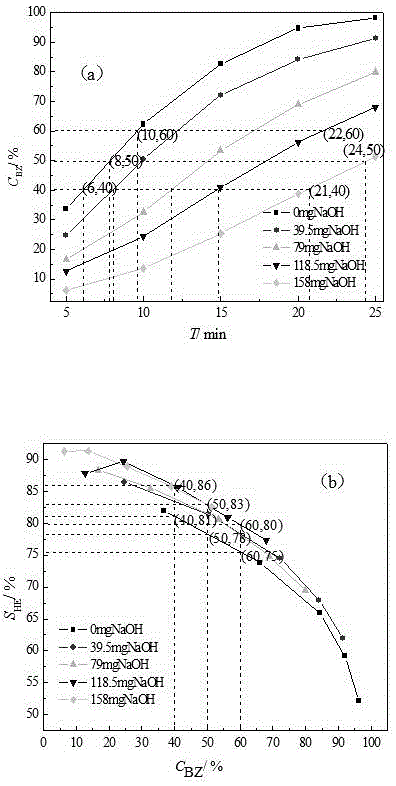

[0017] Embodiment 1~5--Adopt NaOH modulation

[0018] In the reaction slurry containing 2gRu-Zn catalyst and 280ml0.47mol / L zinc sulfate, add 0mg, 39.5mg, 79mg, 118.5mg, 158mgNaOH respectively, the pH of the reaction slurry is between 5.5~6.0; then add this reaction slurry Into a PTFE-lined 1L autoclave, first replace the air in the autoclave with hydrogen, then fill the hydrogen to a pressure of 5MPa, control the stirring speed at 800r / min, raise the temperature to 150°C, feed 140ml of benzene, and increase the stirring speed at the same time. Start timing at 1400r / min, take samples every 5 minutes, use gas chromatograph to analyze product composition, FID detector, area correction and normalization method to calculate the relative content of cyclohexane, cyclohexene and benzene, and calculate the conversion rate of benzene at different times C BZ , Cyclohexene selectivity S HE and yield Y HE . Benzene conversion C BZ , cyclohexene selectivity S HE and yield Y HE Calcu...

Embodiment 6~12

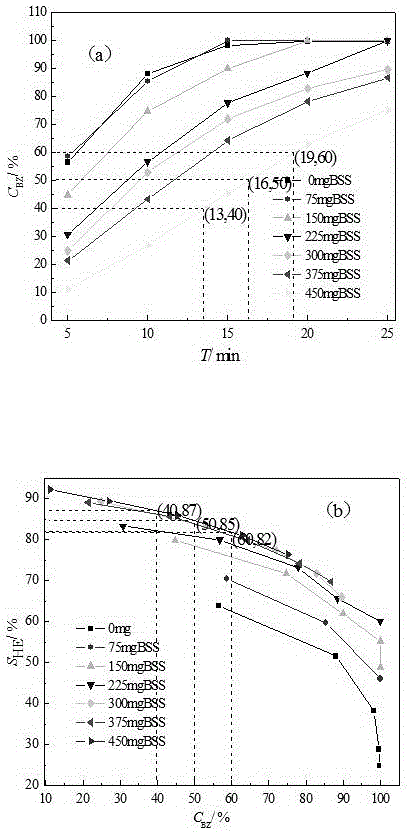

[0023] Embodiment 6~12--Adopt basic formula zinc sulfate modulation

[0024] In the reaction slurry containing 2gRu-Zn catalyst and 280ml0.47mol / L zinc sulfate, add 0mg, 75mg, 150mg, 225.5mg, 300mg, 375mg, 450mg basic zinc sulfate 3Zn(OH) 2· ZnSO 4 ·3H 2 For the colloidal solution of O (based on the mass equivalent to basic zinc sulfate BSS), the pH of the reaction slurry is between 5.1 and 6.2; the follow-up operations are the same as those in Examples 1 to 5.

[0025] figure 2 The change law of catalyst activity and selectivity is given by adding different amounts of basic zinc sulfate BSS, where (a) the conversion rate of benzene after adding different amounts of basic zinc sulfate BSS C BZ The change curve of % with time T, (b) is the cyclohexene selectivity S after adding different amounts of basic zinc sulfate BSS HE % with benzene conversion rate C BZ % change curve. 0 mgBSS was a blank test, and in 7 different embodiments, keeping other conditions unchanged, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com