Tunable metamaterial structure based on variable surface square resistance and manufacturing method thereof

A technology of surface square resistance and metamaterials, which is applied in the photolithographic process of patterned surface, optical mechanical equipment, optics, etc., can solve the problems of complex manufacturing process and high requirements, achieve obvious modulation effect, convenient manufacturing and integration, preparation Simple effects of crafting and tuning methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

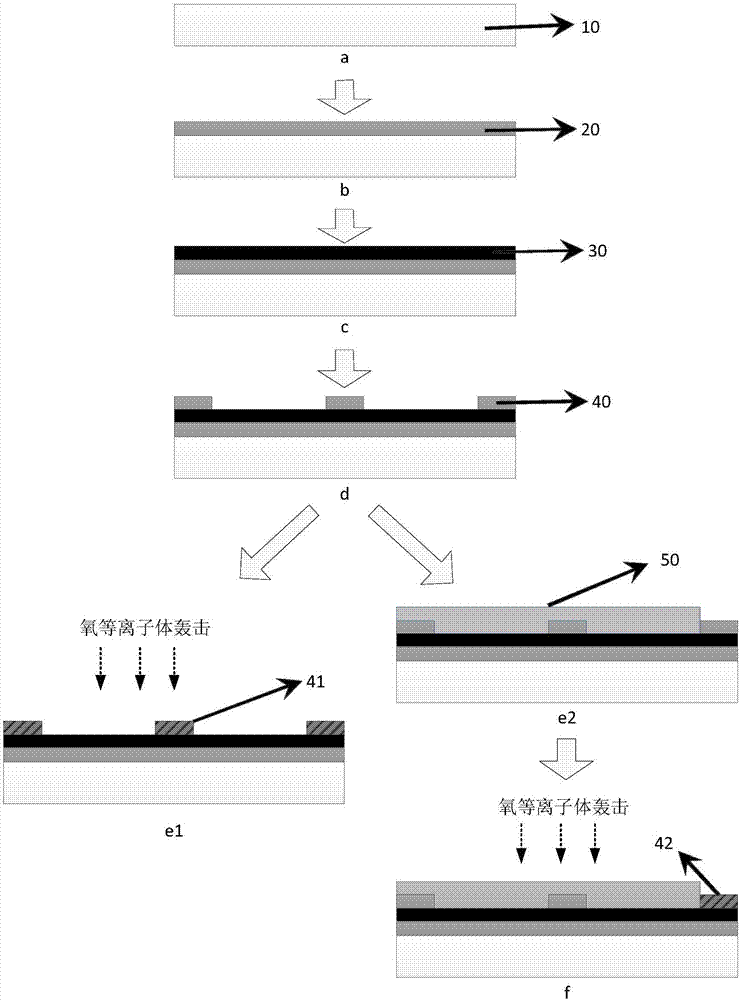

[0039] A tunable metamaterial structure based on variable surface resistance, including a metal thin film bottom layer 20, an intermediate dielectric layer 30, and a patterned metal thin film top layer 40 with adjustable square resistance. The preparation steps of the above-mentioned tunable metamaterial structure based on all variable surface resistance are as follows:

[0040] S1: Prepare the substrate 10.

[0041] S2: The metal thin film bottom layer 20 is prepared by magnetron sputtering. The material of the metal thin film bottom layer 20 is titanium, and the thickness of the metal thin film bottom layer 20 is 100nm-500nm. During the preparation process, the sputtering power is 50-250W, and the pressure of the reaction chamber is It is 1-10Pa, and the sputtering time is 10-30 minutes.

[0042] S3: Prepare the intermediate medium layer 30 by spin coating, the material of the intermediate medium layer 30 is PI, during the preparation process, the forward rotation speed is ...

Embodiment 2

[0046] A tunable metamaterial structure based on variable surface resistance, including a metal thin film bottom layer 20, an intermediate dielectric layer 30, a patterned metal thin film top layer 40 and a dielectric protection layer 50 with adjustable partial square resistance.

[0047] The above-mentioned method for preparing a tunable metamaterial structure based on partially variable surface resistance, the steps are as follows:

[0048] S1: Prepare the substrate 10.

[0049] S2: The metal thin film bottom layer 20 is prepared by magnetron sputtering. The material of the metal thin film bottom layer 20 is titanium, and the thickness of the metal thin film bottom layer is 100nm-500nm. During the preparation process, the sputtering power is 50-250W, and the pressure in the reaction chamber is 1-10Pa, sputtering time is 10-30 minutes.

[0050] S3: Prepare the intermediate medium layer 30 by spin coating, the material of the intermediate medium layer 30 is PI, and the forwar...

Embodiment 3

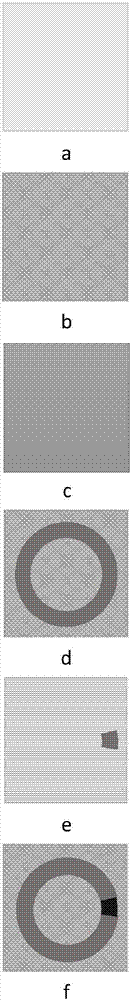

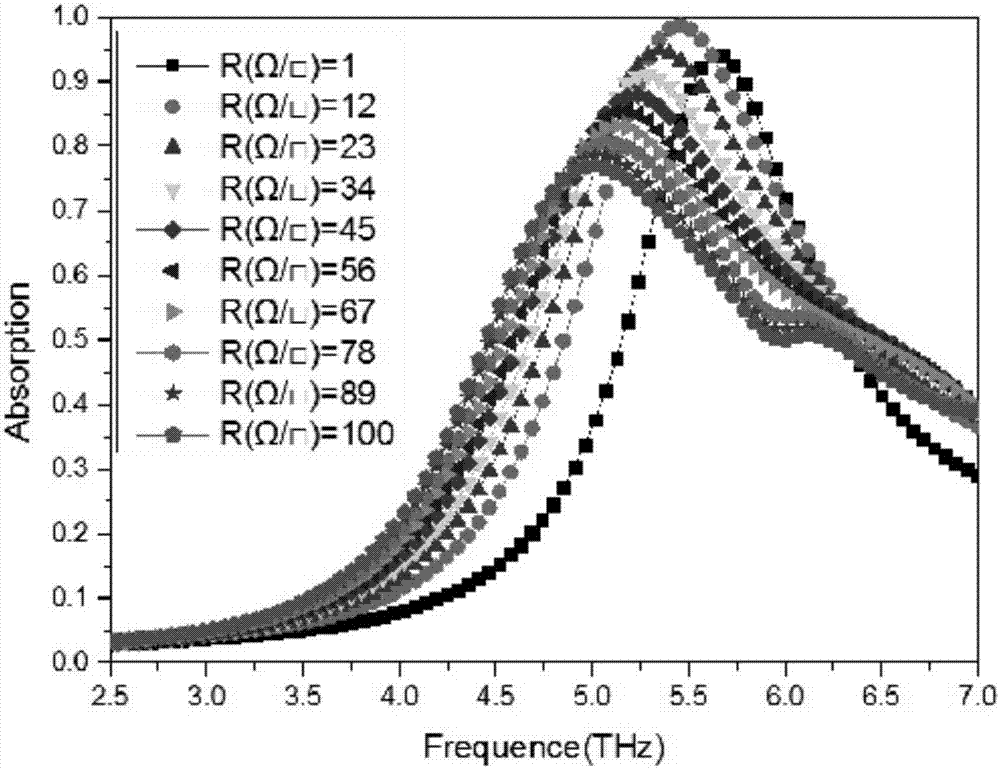

[0056] Such as figure 2 A tunable resonant ring metamaterial structure based on variable surface resistance and its preparation method are shown.

[0057] Prepare the underlying metal film by magnetron sputtering, adjust the process parameters, and control the thickness of the metal film to 400nm, such as figure 2 As shown in a; the intermediate silicon nitride dielectric layer is prepared by PECVD, and the thickness of the dielectric film is controlled to be 4.5 μm, such as figure 2 Shown in b; adopt magnetron sputtering method to prepare top layer metal thin film, adjust process parameter, control metal thin film thickness is 100nm, as figure 2 As shown in c; photolithography and reactive ion etching are used to pattern the top metal film, and the active etchant in the etching gas is BCl 3 and Cl 2 ;Neutral gas N 2 , set BCl 3 , Cl 2 , N 2 The flow ratio is 1:2:1, the RF power is 150W, and the reaction chamber pressure is 3Pa. Controlling the reactive ion etching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com