Textile Color Fastness Blue Series Standard Fabric and Its Application

A color fastness and blue-based technology, applied in textiles, papermaking, textiles, fabrics, etc., to achieve the effects of broad application prospects, good wear resistance, and reduced subjective influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

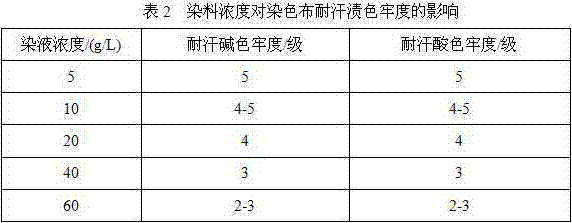

[0031] Example 1 Textile standard blue fabric for rubbing color fastness and its application

[0032] Example 1 Textile color fastness to rubbing blue is a standard fabric, selecting No. 1-8 sample cloth, which uses cotton plain weave as the grey cloth, and is obtained by the following specific preparation method:

[0033] Step (1) Pre-treatment: scouring, bleaching, singeing and mercerizing of the grey fabric;

[0034] The cotton plain weave cloth has a density of 14*14 / 60*60, a strength of 673N*687N, and a weight of 232g / m 2 , Specifically choose the pure cotton plain weave of Nantong Ruiruisheng;

[0035] The scouring and bleaching process is the first rolling liquid, the first steaming, the first water washing, the second rolling liquid, the second steaming, the second water washing, and the drying. The first rolling liquid is selected Caustic soda 50g / L, refining agent 88 8g / L, chelating dispersant 510 3g / L; the first steaming is 100°C steaming for 60 minutes; the first washing u...

Embodiment 2

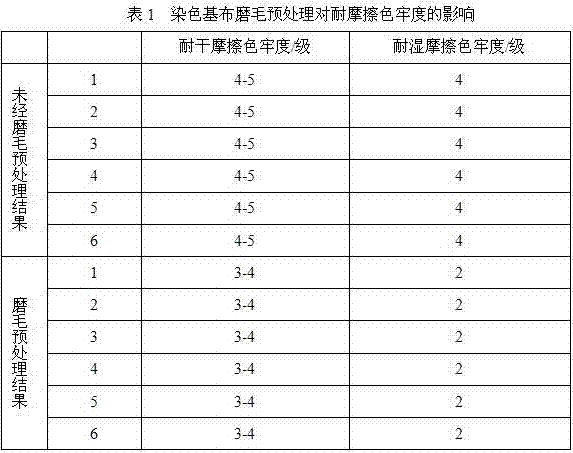

[0045] Example 2 Blue standard fabric of textile color fastness to perspiration and its application

[0046] Example 2 Textile color fastness to perspiration blue is a standard fabric, selected 1-4 sample cloth, which uses cotton plain weave as the grey cloth, and is obtained by the following specific preparation method:

[0047] Step (1) Pre-treatment: scouring, bleaching, singeing and mercerizing of the grey fabric;

[0048] The cotton plain weave cloth has a density of 14*14 / 60*60, a strength of 673N*687N, and a weight of 232g / m 2 , Specifically choose the pure cotton plain weave of Nantong Ruiruisheng;

[0049] The scouring and bleaching process is the first rolling liquid, the first steaming, the first water washing, the second rolling liquid, the second steaming, the second water washing, and the drying. The first rolling liquid is selected Caustic soda 50g / L, refining agent 88 8g / L, chelating dispersant 510 3g / L; the first steaming is 100°C steaming for 60 minutes; the first wa...

Embodiment 3

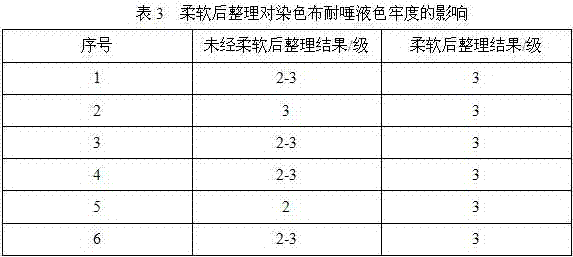

[0057] Example 3 The blue standard fabric of textile color fastness to saliva and its application

[0058] Example 3 The color fastness of textiles to saliva is blue as a standard fabric. Sample cloth 1-4 is selected, which uses cotton plain weave as the grey cloth and is obtained by the following specific preparation method:

[0059] Step (1) Pre-treatment: scouring, bleaching, singeing and mercerizing of the grey fabric;

[0060] The cotton plain weave cloth has a density of 14*14 / 60*60, a strength of 673N*687N, and a weight of 232g / m 2 , Specifically choose the pure cotton plain weave of Nantong Ruiruisheng;

[0061] The scouring and bleaching process is the first rolling liquid, the first steaming, the first water washing, the second rolling liquid, the second steaming, the second water washing, and the drying. The first rolling liquid is selected Caustic soda 50g / L, refining agent 88 8g / L, chelating dispersant 510 3g / L; the first steaming is 100°C steaming for 60 minutes; the fir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com