Method for oil displacement using carbon dioxide and foam

A technology of carbon dioxide and foam flooding, which is applied in the direction of earthwork drilling, production fluid, wellbore/well components, etc. It can solve the problem of extremely large density difference, achieve the effect of simple operation and improve oil displacement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

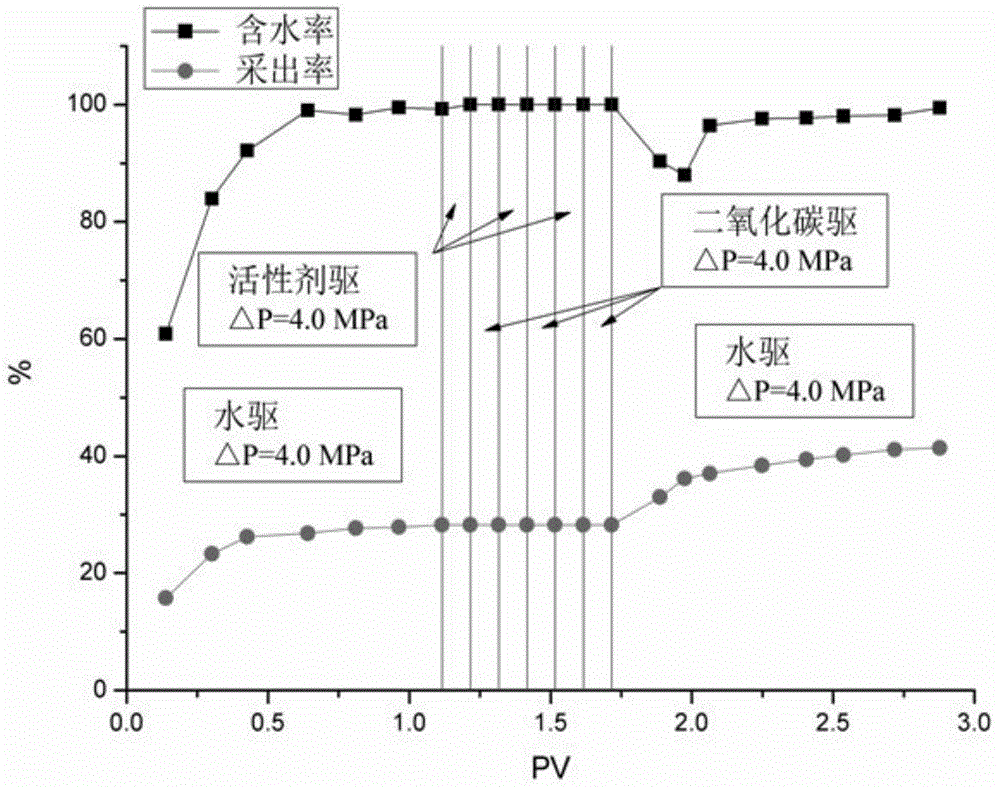

example 1

[0016] The nonionic surfactant alkyl glucoside (APG1214) mass fraction of preparation is 0.3%, and the aqueous solution of NaCl content is 60g / L.

[0017] The following steps are all carried out under the condition of simulated formation temperature of 50°C.

[0018] For a diameter of 2.50 cm and a length of 10.0 cm, saturated water and saturated oil are processed. The core parameters of this experiment are: porosity 15.19%, pore volume 7.364mL, gas permeability 8.035mD, original oil saturation 44.3%.

[0019] Carry out water flooding on the above core until the water content at the outlet exceeds 98%, the injection pressure is 4.0MPa, and the water flooding efficiency is 28.2%.

[0020] Under the condition of injection pressure of 4.0MPa, 0.1PV of the prepared surfactant solution and 0.1PV of carbon dioxide gas were injected alternately three times, with a total injection volume of 0.6PV.

[0021] Subsequent water flooding until the water content at the outlet is above 98%,...

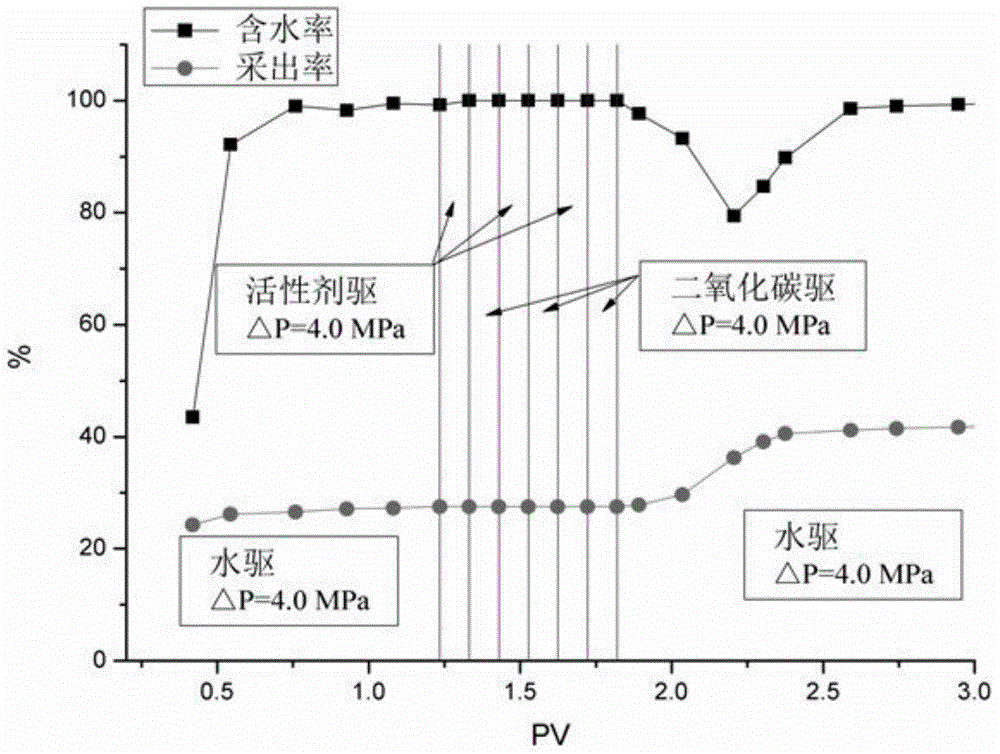

example 2

[0023] Prepare two types of ionic surfactant cocamidopropyl betaine (CAB-35) mass fraction is 0.3%, NaCl content is the aqueous solution of 60g / L.

[0024] The following steps are all carried out under the condition of simulated formation temperature of 50°C.

[0025] For a diameter of 2.50 cm and a length of 10.0 cm, saturated water and saturated oil are processed. The core parameters of this experiment are: porosity 14.89%, pore volume 7.180mL, gas permeability 7.271mD, original oil saturation 52.5%.

[0026] Carry out water flooding on the above core until the water content at the outlet exceeds 98%, the injection pressure is 4.0MPa, and the water flooding efficiency is 27.4%.

[0027] Under the condition of injection pressure of 4.0MPa, 0.1PV of the prepared surfactant solution and 0.1PV of carbon dioxide gas were injected alternately three times, with a total injection volume of 0.6PV.

[0028] Subsequent water flooding until the water content at the outlet is above 98%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com