Electric submersible pump spline coupling structure for integrated well

A submersible electric pump and spline shaft technology, which is applied to components, pumps, and pump components of a pumping device for elastic fluids, can solve problems such as difficulty in ensuring coaxiality, difficulty in processing, high cost, and loud noise. , to achieve the effect of reducing machining accuracy requirements and installation requirements, reducing production costs, and simple installation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

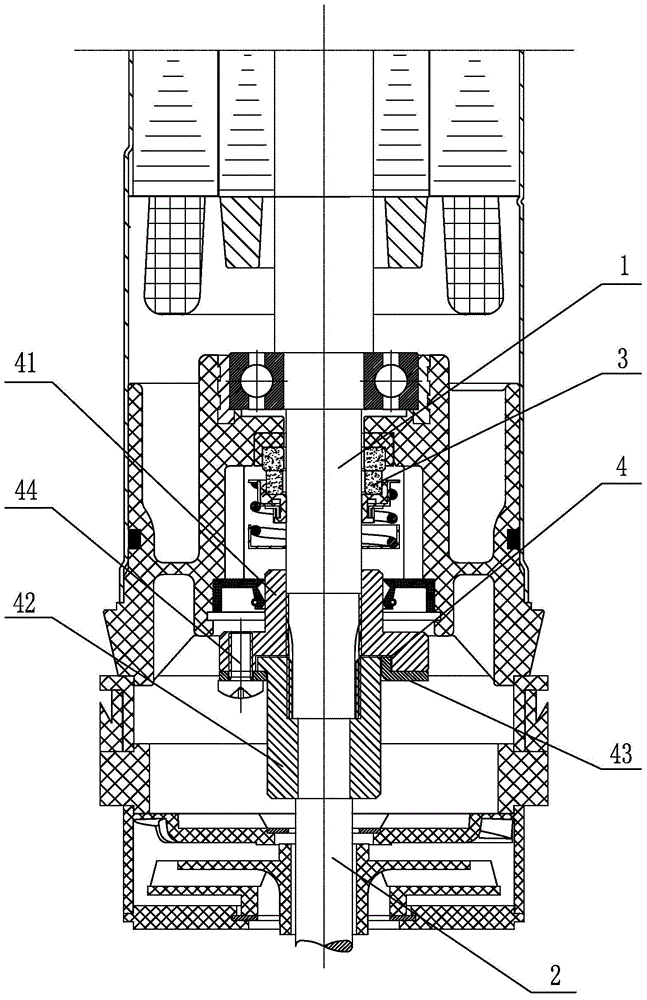

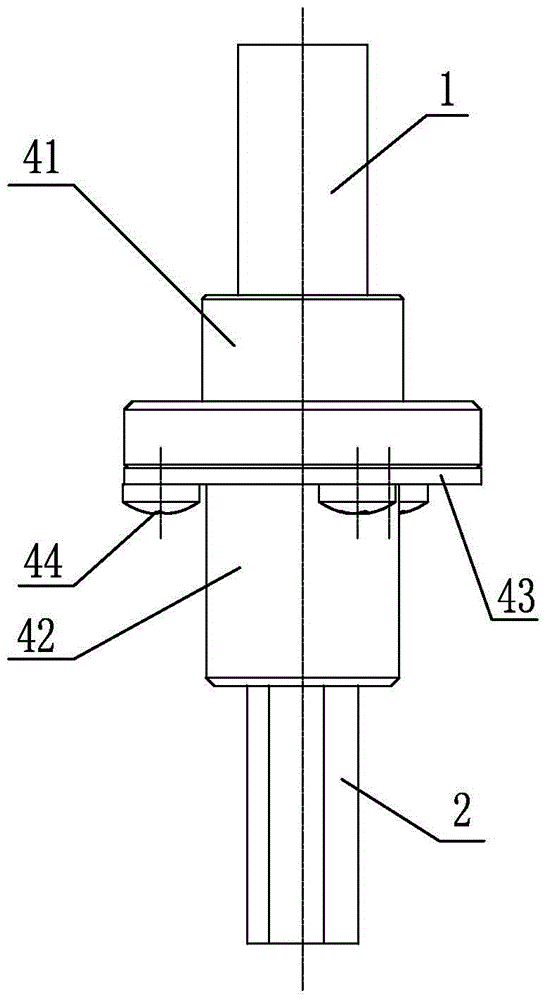

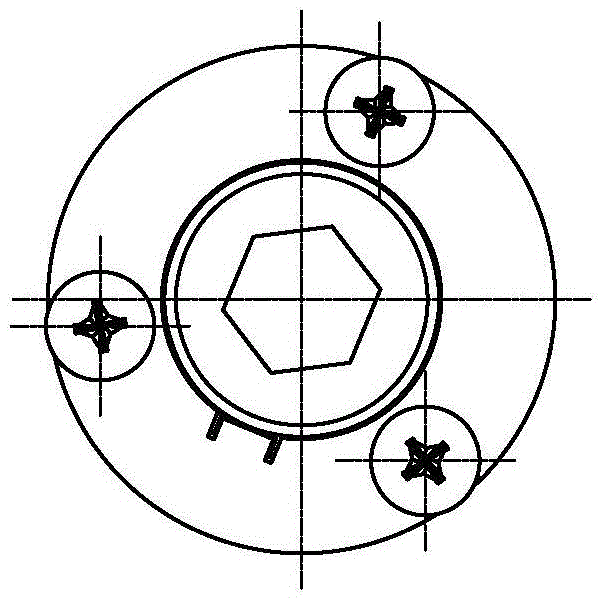

[0032] Depend on Figure 1-22 As shown, the embodiment of the spline coupling structure of the integrated well submersible pump of the present invention is: it includes the motor output spline shaft end 1 and the water pump input hexagonal shaft end 2, and the coupling position between them is installed on the motor output spline shaft end. Below the mechanical seal 3 on the key shaft end 1, the motor output spline shaft end 1 and the water pump input hexagonal shaft end 2 are connected by a coupling 4, which includes an upper half coupling 41 and a lower half coupling 41. The half coupling 42, the body of the upper half coupling 41 is a flange with a flange at the center, with a central threaded shaft hole 411, and the flange has connecting screw holes 412 evenly distributed around the circumference. There is also a counterbore 413 in the center of the bottom surface of the blue plate. The body of the lower half coupling 42 is a cylinder with a flange 423 at the end, and a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com