Integrated well submersible electric pump spline coupling structure

A technology of submersible electric pump and spline shaft, which is applied to parts, pumps, and pump components of pumping devices used for elastic fluids, and can solve the problems of difficult guarantee of coaxiality, difficulty and high cost of processing, and high processing cost , to achieve the effect of reducing processing accuracy requirements and installation requirements, reducing production costs, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

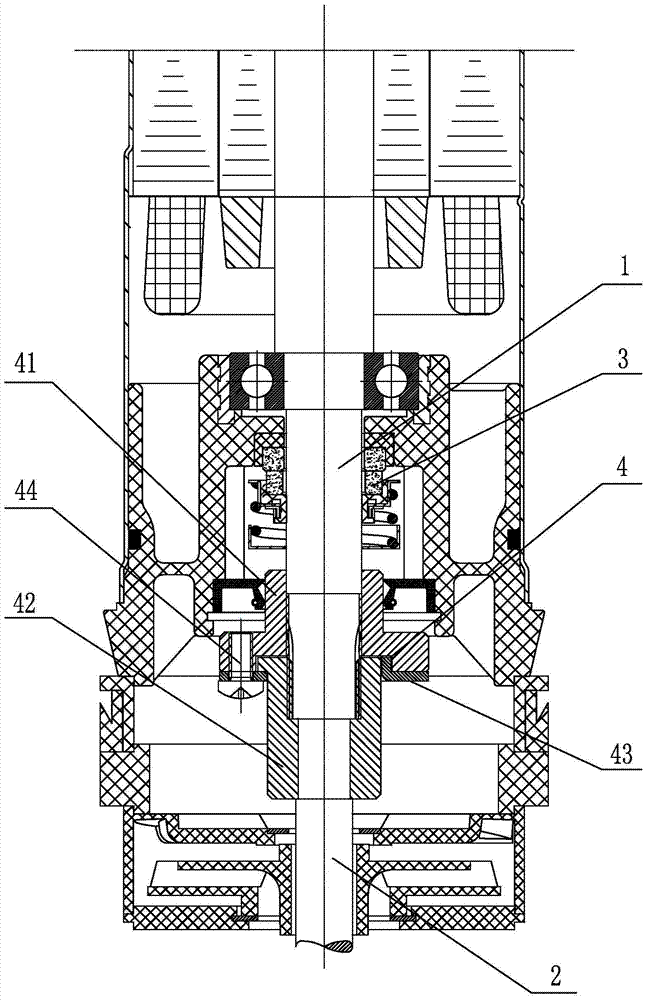

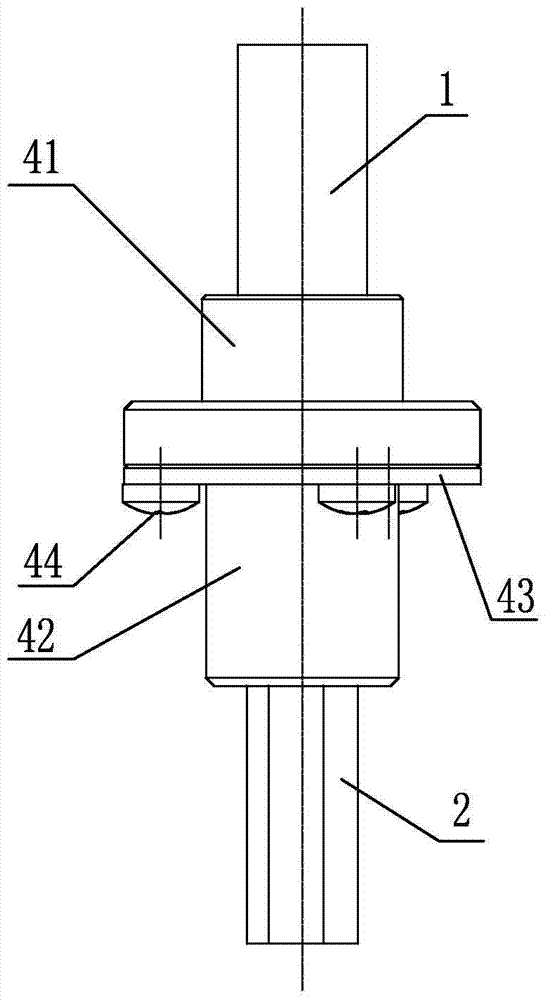

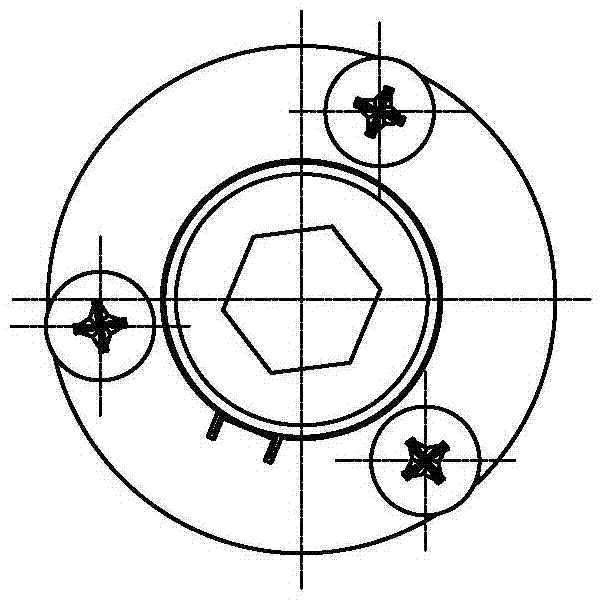

[0032] Depend on Figure 1-22 As shown, the embodiment of the spline coupling structure of the integrated well submersible pump of the present invention is: it includes the motor output spline shaft end 1 and the water pump input hexagonal shaft end 2, and the coupling position between them is installed on the motor output spline shaft end. Below the mechanical seal 3 on the key shaft end 1, the motor output spline shaft end 1 and the water pump input hexagonal shaft end 2 are connected by a coupling 4, which includes an upper half coupling 41 and a lower half coupling 41. The half coupling 42, the body of the upper half coupling 41 is a flange with a flange at the center, with a central threaded shaft hole 411, and the flange has connecting screw holes 412 evenly distributed around the circumference. There is also a counterbore 413 in the center of the bottom surface of the blue plate. The body of the lower half coupling 42 is a cylinder with a flange 423 at the end, and a ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com