an ultra-low no x gas burner

A gas burner, ultra-low technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve the problems of easily causing vibration, high energy consumption, difficult to promote, etc., to improve work reliability and meet the requirements of low NOx Emission requirements, effect of diluting furnace oxygen content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and typical embodiments.

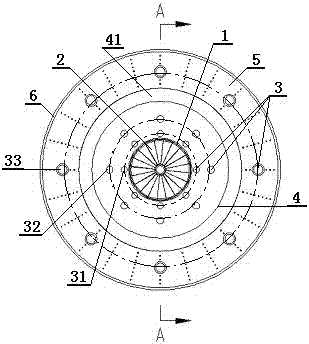

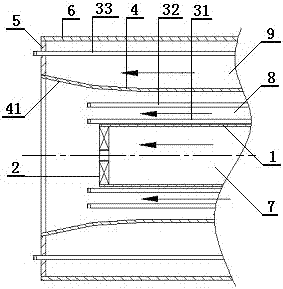

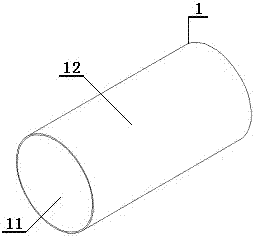

[0024] exist Figure 1 to Figure 8 In the present invention, the ultra-low NO X The main body of the gas burner includes a central tube 1, a swirler 2, a gas gun group 3, a throat 4, a front panel 5 and a casing 6, and it is characterized in that: the main body of the central tube 1 is a middle tube cavity 11 and a surrounding A cylindrical body composed of a cylinder wall 12; the main body of the cyclone 2 is in the shape of a ring, including an inner ring 21 with a central through hole, and the outer diameter is in line with the inner diameter of the central cylinder 1 The outer ring 22 of the inner ring 21 and the curved streamlined vane 23 arranged between the outer ring surface of the inner ring 21 and the inner ring face of the outer ring 22; There are several gas front injection holes A311, several internal gas guns 31 with several gas ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com