Part for increasing convective heat transfer coefficient of condensate, refrigerating system and cooling and heating air conditioner

A technology of convection heat transfer coefficient and condensate, which is used in evaporators/condensers, refrigerators, refrigeration components, etc., and can solve the problems of affecting the supercooling effect of condensate, reducing the flow rate U, and reducing the volume flow rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

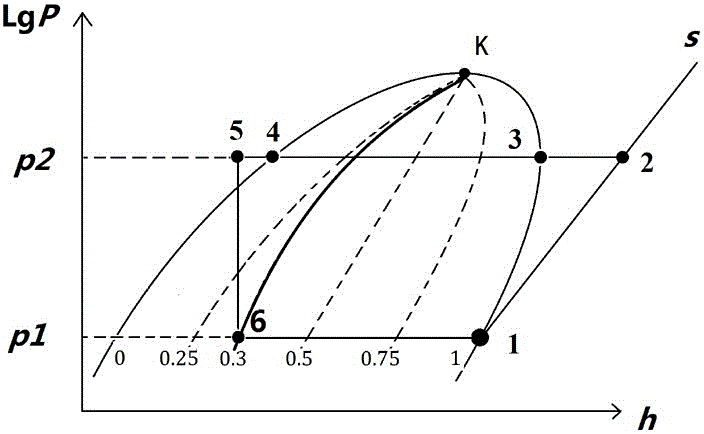

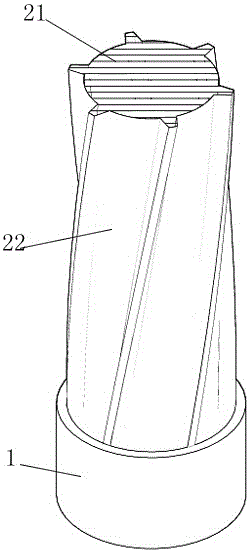

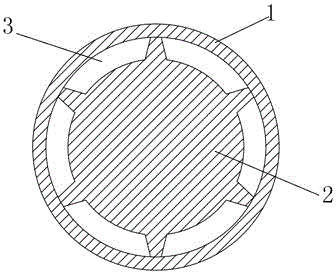

[0044] The invention provides a component for improving the convective heat transfer coefficient of the condenser condensate, by implanting a component in the end pipeline of the condenser (such as a copper tube), focusing on improving the "condensation phase transition" of the refrigerant gas in the condenser After the "exothermic process", it enters the "supercooling stage" of the condensate, that is, the flow rate of the condensate entering the "end" of the condenser, increasing the Reynolds number of the condensate flow, reducing the thickness of the boundary layer, thereby reducing the heat flow at the end of the condenser from the inside The first stage of the outer three-stage heat transfer is "condensate in the pipeline → the inner surface of the pipeline", which restricts the overall three-stage heat transfer coefficient. The key stage of the low convective heat transfer coefficient of the condensate The thermal resistance (three-stage heat transfer at the end of the c...

Embodiment 2

[0052] The invention provides a refrigeration system, which includes a compressor, an evaporator, a throttling device and a condenser, and the compressor, the evaporator, the throttling device and the condenser are sequentially connected to form a circulation channel for refrigerant circulation; the end of the condenser The components as described in the first embodiment are arranged in the pipeline.

[0053] And because looking along the flow of the condenser pipeline, the condenser has to undertake the "exothermic cooling of the high-temperature superheated sensible heat part" and "condensation and exothermic liquefaction of saturated refrigerant gas" of the high-temperature and high-pressure refrigerant gas delivered by the compressor. " and "further cooling and subcooling of the condensate" such three-stage heat release tasks (compared with the previously mentioned "from the perspective of the section perpendicular to the refrigerant pipeline at the end of the condenser, fr...

Embodiment 3

[0063] refer to Figure 9 , the present invention provides a heating and cooling air conditioner, the heating and cooling air conditioner includes a compressor 4, a first heat exchanger 11, a throttling device 6 and a second heat exchanger 12, the compressor 4, the first heat exchanger 11, a throttling The device 6 and the second heat exchanger 12 are sequentially connected to form a cycle for refrigerant circulation; the compressor 4 is connected to the first heat exchanger 11 and the second heat exchanger 12 through a four-way valve 10, wherein the first heat exchanger 11 It is an indoor unit, and the second heat exchanger 12 is an outdoor unit. In the present invention, by adjusting the four-way valve 10, the first heat exchanger 11 is used as a condenser or the second heat exchanger 12 is used as a condenser. During cooling in summer, the second heat exchanger 12 of the outdoor unit is used as a condenser, and the first heat exchanger 11 of the indoor unit is used as an ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com