A detection method for determining short-term failure water pressure of bamboo composite pressure pipes

A technology of bamboo composite pressure pipe and detection method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the requirements of reducing the test conditions of large diameter bamboo composite pressure pipe, inaccurate short-term failure hydraulic pressure results, etc. problems, to achieve the effect of accurate short-term failure water pressure, reducing pressure time, and reducing interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

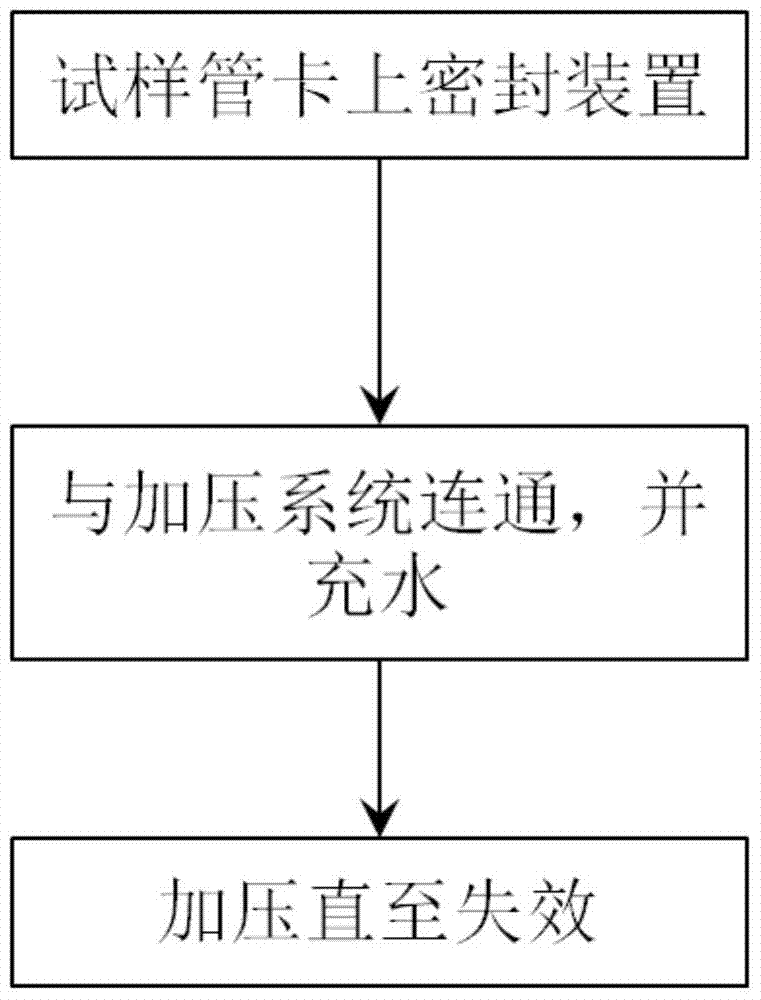

[0025] figure 1 Shown is a schematic flow chart of the short-time failure hydraulic method for detecting bamboo composite pressure pipes.

[0026] The nominal diameter of bamboo composite pressure pipe G1 to be tested is D N is 300mm, and the pressure level is 0.8MPa, then G1 is the sample S1.

[0027] Place S1 in an air environment at 25°C for 16 hours, and then attach a sealing device to both ends of the sample S1. The sealing device has a sealing plug, and the edge of the sealing plug in contact with S1 is chamfered. Support the sealing device so that the sample S1 is in a horizontal state, and the sealing device is a constraint end sealing device; then, connect the sealing device with a pressurized system, the pressurized system is an electric pressure test pump, and then fill the sample with Water, so that the sample is filled with water and the air is exhausted; the time for the sample to be filled with water from the beginning of water to full of water is 5 minutes; ...

Embodiment 2

[0031] The nominal diameter of bamboo composite pressure pipe G2 to be tested is D N The diameter is 800mm, the pressure level is 0.6MPa, and the measured ring stiffness is 8240N / m 2 , let G2 be the sample S2. In addition, the selected scaling ratio is 2:1 (that is, the scaling factor λ=D N :D N '=2) the bamboo composite pressure pipe is used as the reduction pipe G2' of the pipe G2, and the nominal diameter D of the pipe G2' N’ is 400mm, the pressure level is 0.3MPa, and the ring stiffness is 4120N / m 2 , taking G2' as sample S2';

[0032] Place S2 and S2' in an air environment at 25°C for 16 hours, and then attach sealing devices to both ends of samples S2 and S2' respectively, and support the sealing devices so that both samples S2 and S2' are in a horizontal state. The above-mentioned sealing devices are all sealing devices at the constraining end; then, connect the sealing device with the pressurized system, which is a nitrogen cylinder pressure supply system with a p...

Embodiment 3

[0035] Bamboo composite pressure pipe G3 to be tested, nominal diameter D N is 800mm, the pressure level is 0.6MPa, and the measured ring stiffness is 8240N / m 2 , let G3 be the sample S3. In addition, select the bamboo composite pressure pipe shrinkage pipe G3' of the pipe G3, and the nominal diameter of the pipe G3' is D N ’=200mm, the reduction ratio is 4:1 (that is, the scale factor λ=D N :D N ’=4), the nominal diameter, pressure level, and ring stiffness ratio of both G3 and G3’ are 4, and G3’ is taken as sample S3’;

[0036] Place S3 and S3' in an air environment at 25°C for 16 hours, and then attach sealing devices to both ends of samples S3 and S3' respectively, and support the sealing devices so that both samples S3 and S3' are in a horizontal state. The sealing devices mentioned above are all sealing devices at the constraining end; then, connect the sealing device with the pressurized system, and then fill the samples S3 and S3' with water respectively, so that t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| voltage rating | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com