An electric servo control method and system for a refractory brick press feeder

An electric servo and control method technology, applied in electrical program control, program control in sequence/logic controllers, etc., can solve the problems of being easily affected by the oil state, low overload capacity, oil leakage in the oil circuit, etc. System response speed and stability, strong environmental adaptability, and the effect of improving control accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

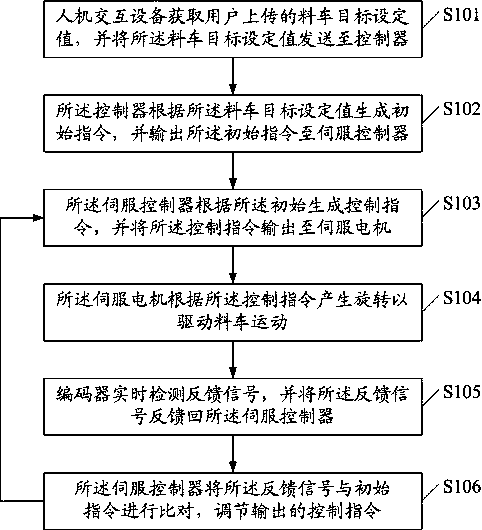

[0031] figure 2 It is the flow chart of the first embodiment of the electric servo control method for the refractory brick press skip of the present invention, including:

[0032] S101. The human-computer interaction device acquires the target setting value of the material truck uploaded by the user, and sends the target setting value of the material vehicle to the controller.

[0033] The target setting value of the material truck is a position value, but it is not limited thereto, and the target setting value of the material vehicle can also be a speed value or a torque value.

[0034] The user uploads the target setting value of the feeding truck according to the actual needs, so that the electric servo control system used for the feeding truck of the refractory brick press can control the feeding truck and improve the control accuracy.

[0035] S102. The controller generates an initial instruction according to the target set value of the material truck, and outputs the i...

no. 2 example

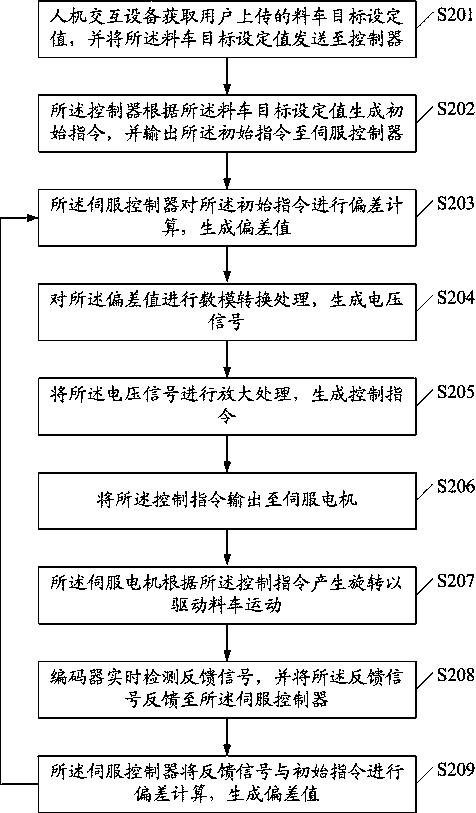

[0044] image 3 It is the flow chart of the second embodiment of the electric servo control method for the refractory brick press skip of the present invention, including:

[0045] S201. The human-computer interaction device acquires the target setting value of the material truck uploaded by the user, and sends the target setting value of the material vehicle to the controller.

[0046] The target setting value of the material truck is a position value, but it is not limited thereto, and the target setting value of the material vehicle can also be a speed value or a torque value.

[0047] The user uploads the target setting value of the feeding truck according to actual needs, so that the electric servo control system used for the feeding truck of the refractory brick press can control the feeding truck.

[0048] S202. The controller generates an initial instruction according to the target set value of the material truck, and outputs the initial instruction to the servo control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com