Method for multi-board card to synchronically and sequentially read multi-path sensor data

A multi-channel sensor and sequential reading technology, which is applied in the direction of instruments, simulators, program control, etc., can solve the problem that the data of laser interferometer and grating sensor cannot be read at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

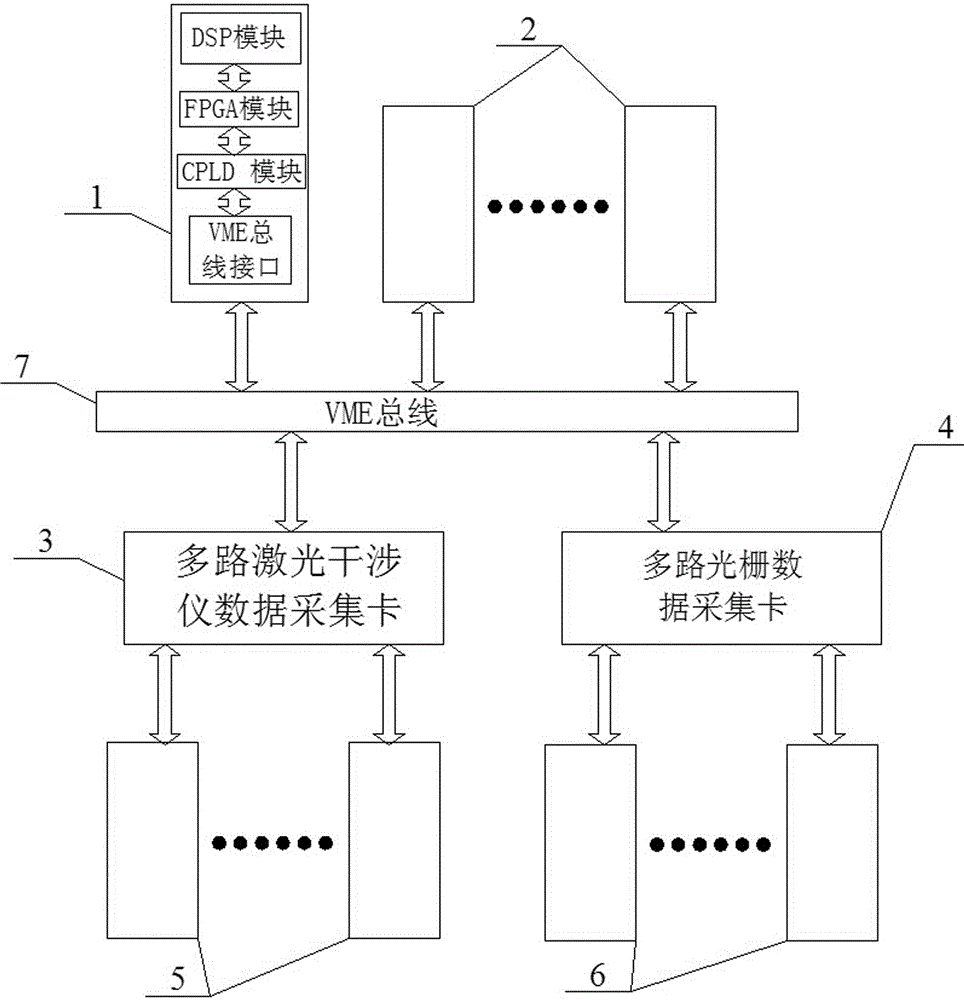

[0014] Specific implementation mode one: combine figure 1 Shown, illustrate the technical scheme of this embodiment, its method step is:

[0015] Step 1: The master card 1 of the motion control card, the slave card 2 of multiple motion control cards, the multi-channel laser interferometer data acquisition card 3 and the multi-channel grating data acquisition card 4 are all connected to the VME bus 7; The laser interferometer data acquisition card 3 updates the collected data from multiple laser interferometers 5 at a frequency of 10 MHz, and assigns these data to different address codes and stores them in the RAM of the multi-channel laser interferometer data acquisition card 3 The multi-channel grating data acquisition card 4 updates the data collected by a plurality of grating sensors 6 at a frequency of 10MHz, and stores these data in the RAM of the multi-channel grating data acquisition card 4 after giving different address codes;

[0016] Step 2: The DSP module in the ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com