Mineral-insulated flexible fire-proof cable coated by high-strength non-magnetic corrugated stainless steel sheath

A technology for mineral insulated and fireproof cables, applied in insulated cables, power cables, insulated conductors, etc., can solve the problems of difficulty in realizing large-diameter, large-length section production, laying and installation, troublesome joints, and the fire resistance temperature cannot be too high. Mechanical and physical properties, good corrosion resistance and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

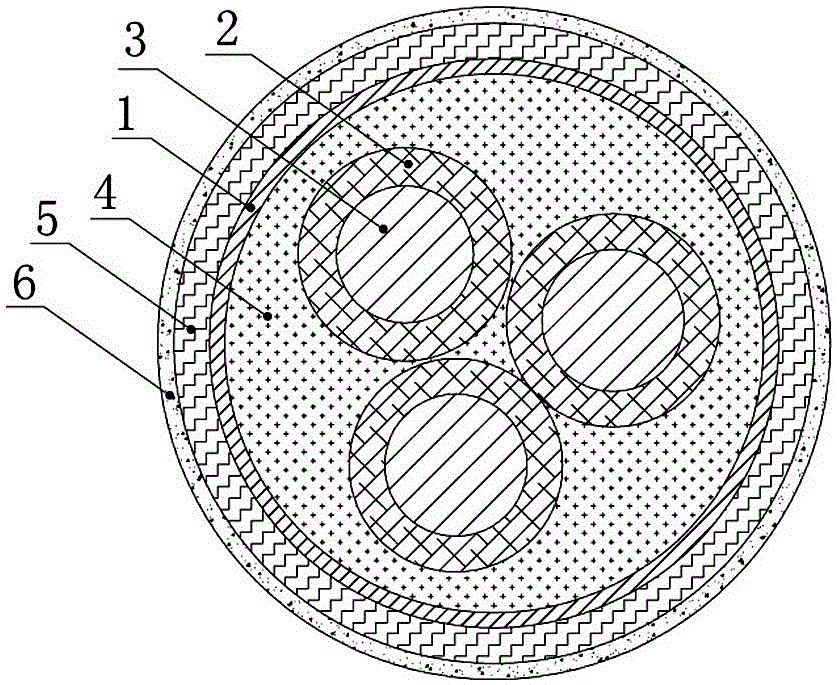

[0024] Such as figure 1 As shown, the high-strength non-magnetic corrugated stainless steel sheathed mineral insulated flexible fireproof cable of the present invention includes three wires 3 arranged in the cabled wrapping layer 1 and wrapped with an insulating layer 2, filled between the insulating layer 2 and the The inorganic heat-insulating fireproof filler 4 between the cabled wrapping layers 1, the corrugated stainless steel sheath 5 coated on the outer peripheral surface of the cabled wrapping layer 1 and the fireproof paint layer 6 sprayed on the outer peripheral surface of the corrugated stainless steel sheath 5;

[0025] The insulating layer 2 is made of an alkali-free glass fiber tape with a thickness of 0.08-0.10mm and a mixed adhesive layer with a thickness of 0.10-0.30mm coated on the inside and outside of the alkali-free glass fiber tape, which is heated and cured at 180°C for 10-20min. The mixed glue used in the layer is calculated by mass percentage, consisti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com