Power diode and preparation method thereof

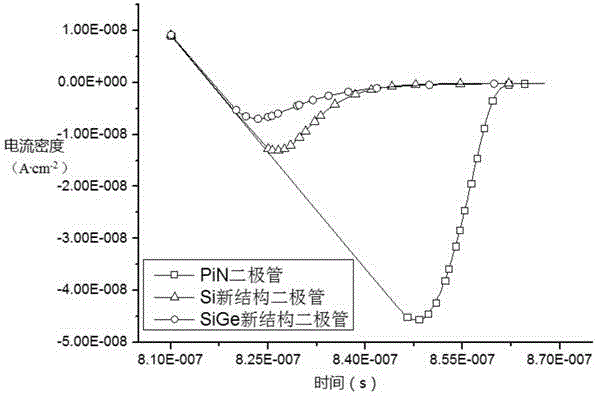

A technology of power diodes and anodes, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as poor reverse recovery performance, achieve fast switching speed, shorten reverse recovery time, and reduce the effect of stored charge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

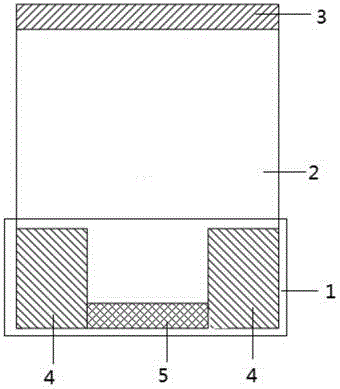

[0050] A method for preparing a power diode, including a cathode N arranged sequentially from bottom to top + Zone 1, voltage-resistant layer 2 and anode P + Zone 3, Cathode N + Zone 1 consists of two N + District 4, N + N zone 5 is set in the middle of zone 4, anode P + The dopants in region 3 are B ions and Ge ions, the content of Ge ions is 10% to 20%, and the N + The dopant of region 4 and N region 5 is P ion, the thickness of withstand voltage layer 2 is 10um-13um, the width is 6um-12um, N + The thickness of zone 4 is 3um~5um, the width is 2um~4um, the thickness of N zone 5 is 0.8um~1.2um, the width is 5um~7um, the cathode N + zone 1 and anode P + Area 3 uses ohmic contacts to form electrodes;

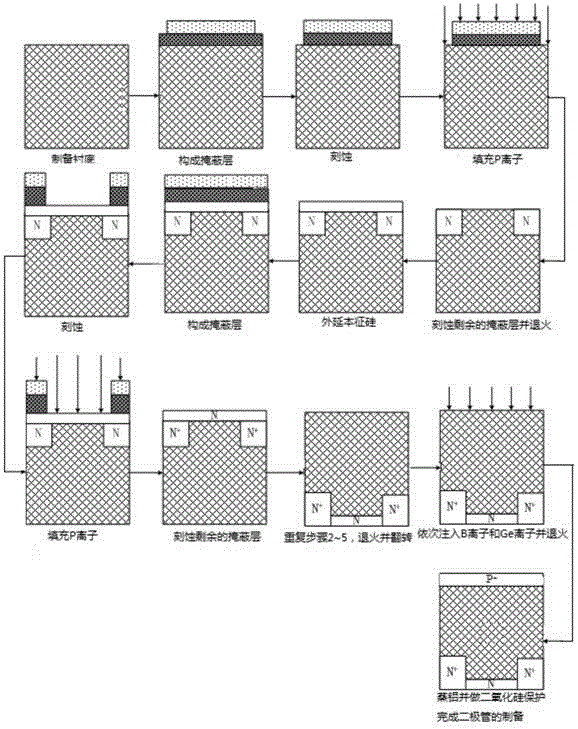

[0051] Specifically, follow the steps below to implement, such as figure 2 Shown:

[0052] Step 1: Prepare the substrate;

[0053] Preparing the substrate Use a silicon single crystal grown along the direction to make a substrate with a thickness of 13.0-13.1um;

[00...

Embodiment 1

[0071] A method for preparing a power diode, the power diode includes cathodes N arranged sequentially from bottom to top + Zone 1, voltage-resistant layer 2 and anode P + Zone 3, Cathode N + Zone 1 consists of two N + District 4, N + N zone 5 is set in the middle of zone 4, anode P + The dopants in region 3 are B ions and Ge ions, the content of Ge ions is 10% to 20%, and the N + The dopant of region 4 and N region 5 is P ion, the thickness of withstand voltage layer 2 is 10um, the width is 6um, N + Region 4 has a thickness of 3um and a width of 2um, N region 5 has a thickness of 0.8um and a width of 5um, and the cathode N + zone 1 and anode P + Area 3 uses ohmic contacts to form electrodes;

[0072] Specifically, follow the steps below to implement, such as figure 2 Shown:

[0073] Step 1: Prepare the substrate;

[0074] Preparation of the substrate Use a silicon single crystal grown along the direction to make a substrate with a thickness of 13.0um;

[0075] St...

Embodiment 2

[0092] A method for preparing a power diode, the power diode includes cathodes N arranged sequentially from bottom to top + Zone 1, voltage-resistant layer 2 and anode P + Zone 3, Cathode N + Zone 1 consists of two N + District 4, N + N zone 5 is set in the middle of zone 4, anode P + The dopants in region 3 are B ions and Ge ions, and the concentration of Ge ions is 0.5×10 22 cm -2 ~1×10 22 cm -2 , N + The dopant of region 4 and N region 5 is P ion, the thickness of withstand voltage layer 2 is 12um, the width is 9um, N + Region 4 has a thickness of 4um and a width of 3um, N region 5 has a thickness of 1um and a width of 6um, and the cathode N + zone 1 and anode P + Area 3 uses ohmic contacts to form electrodes;

[0093] Specifically, follow the steps below to implement, such as figure 2 Shown:

[0094] Step 1: Prepare the substrate;

[0095] Preparation of the substrate Use a silicon single crystal grown along the direction to prepare a substrate with a thick...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com