Gasoline engine charging system

A charging system, gasoline engine technology, applied in electromechanical devices, collectors, electric vehicles, etc., can solve the problems of engine shutdown, crankshaft no output, etc., achieve the effect of simple structure and avoid current mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

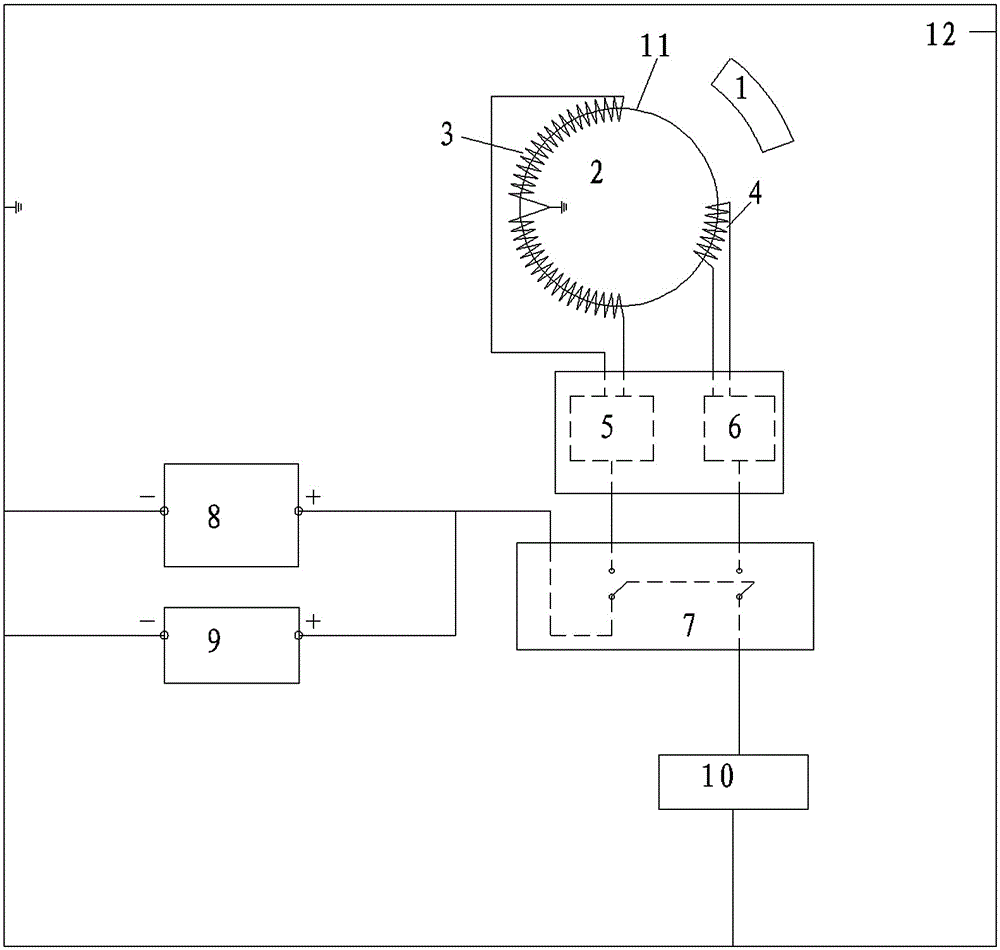

[0018] The present invention will be further described below in conjunction with accompanying drawing.

[0019] see figure 1 As shown, a charging system for a gasoline engine includes a rotor 1 and a stator 2 arranged on a gasoline engine 12, the magnetic poles of the rotor 1 are fixedly mounted on the flywheel of the gasoline engine, and the magnetic poles are mounted on the flywheel and rotate with the crankshaft relative to the crankcase. The rotor 1 is an outer rotor. The stator iron core 11 of the stator 2 is installed on the gasoline engine casing, and the stator iron core 11 is respectively wound with a first charging coil winding 5 and a second charging coil winding 6 which are independent of each other. The number of turns of the coil is more than that of the second charging coil winding 6, because the power of the storage battery connected to the first charging coil winding 5 and the external load are relatively large, and the power of the carburetor solenoid valve ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap