A shell membrane separation method, system and device

A shell-membrane separation and shell-membrane technology, which is applied in solid separation, chemical instruments and methods, grain processing, etc., can solve the problems of large time consumption, high separation cost, and high consumption, so as to save energy and cost, and broaden the development Prospects, efficiency-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

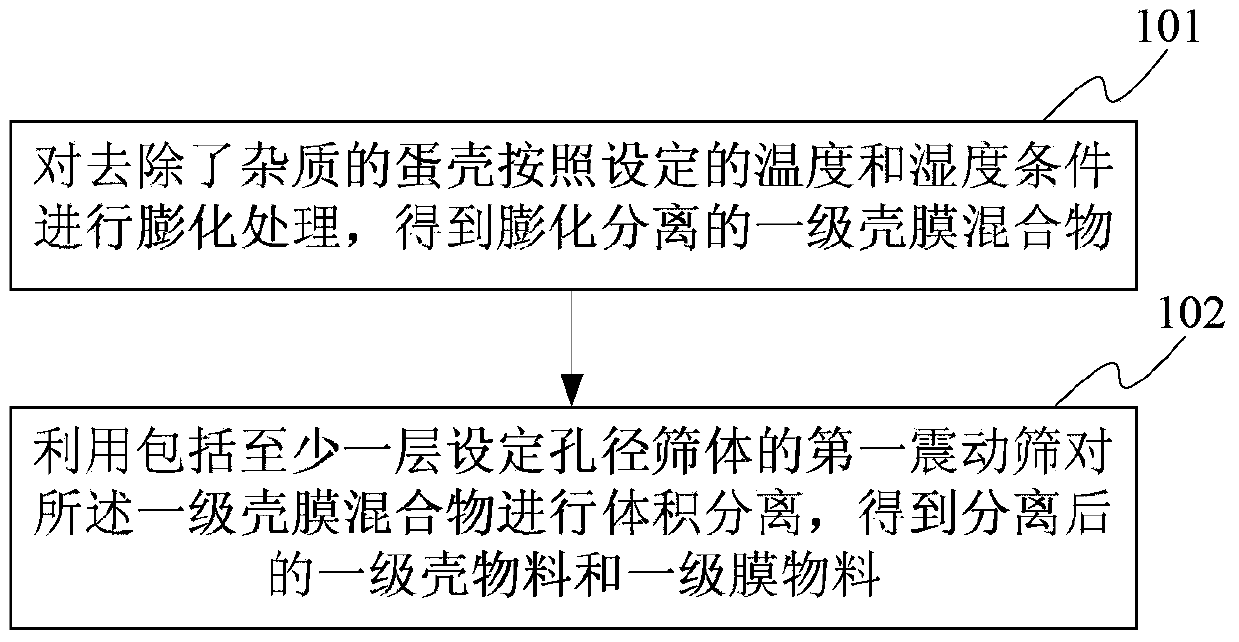

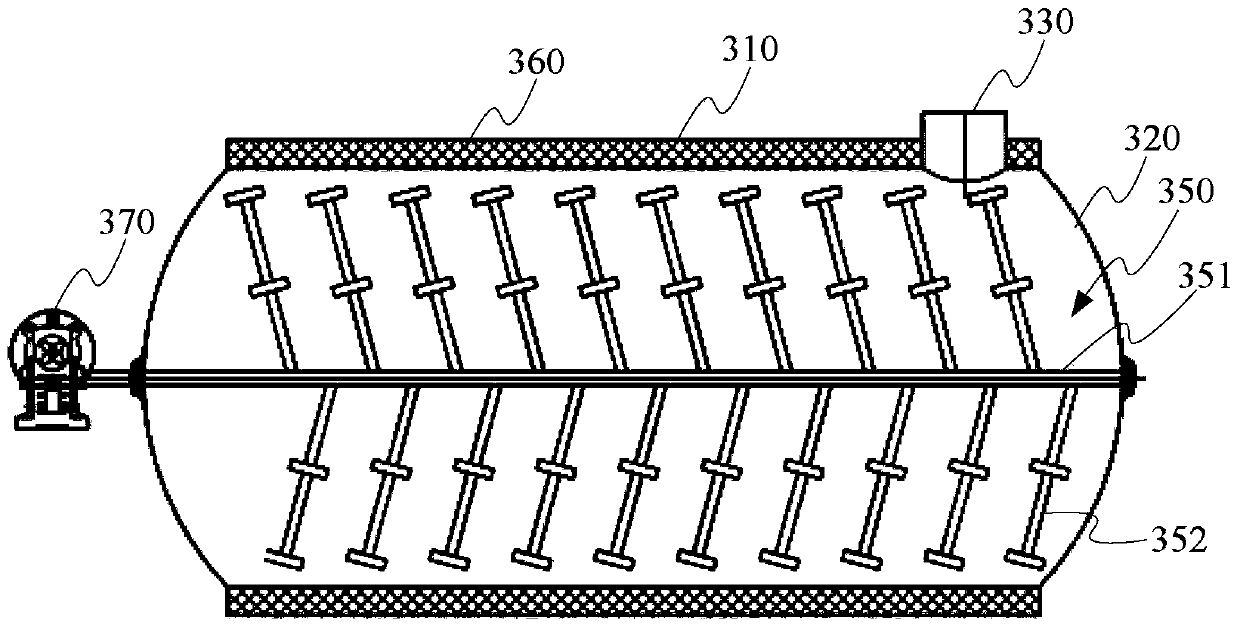

[0037] Considering that in the traditional shell-membrane separation method, the egg shells are soaked in water and then dried and other treatments require a lot of time and energy. In order to improve the efficiency of shell-membrane separation and reduce the cost of shell-membrane separation, the inventor of this case overcomes inertia Thinking, after conducting a lot of experiments, a brand new solution was found, that is, the shell membrane was expanded first, that is to say, under the premise that the membrane in the egg shell has a certain humidity and toughness and the shell itself is dry, Stirring at high temperature prevents the membrane in the eggshell from rupturing as much as possible and the shell falls off the membrane after rupture. This not only realizes the rapid separation of the shell membrane, but also because this method does not need to use a large amount of water to soak the shell, and there is no need to immerse the shell. The process of drying after soak...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com