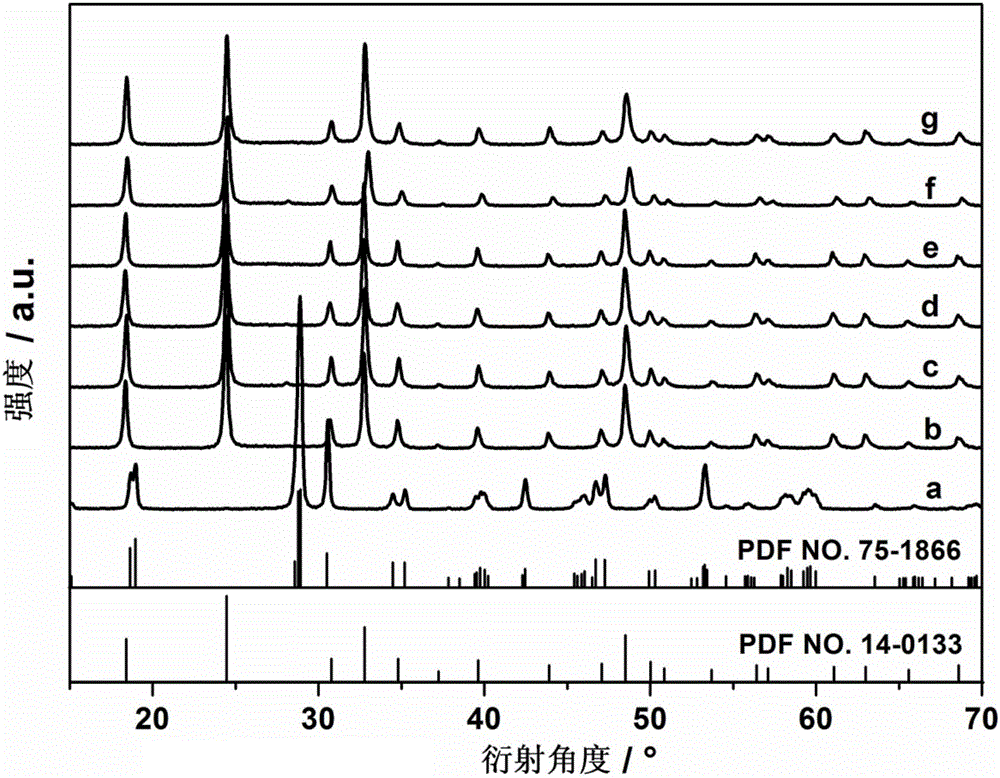

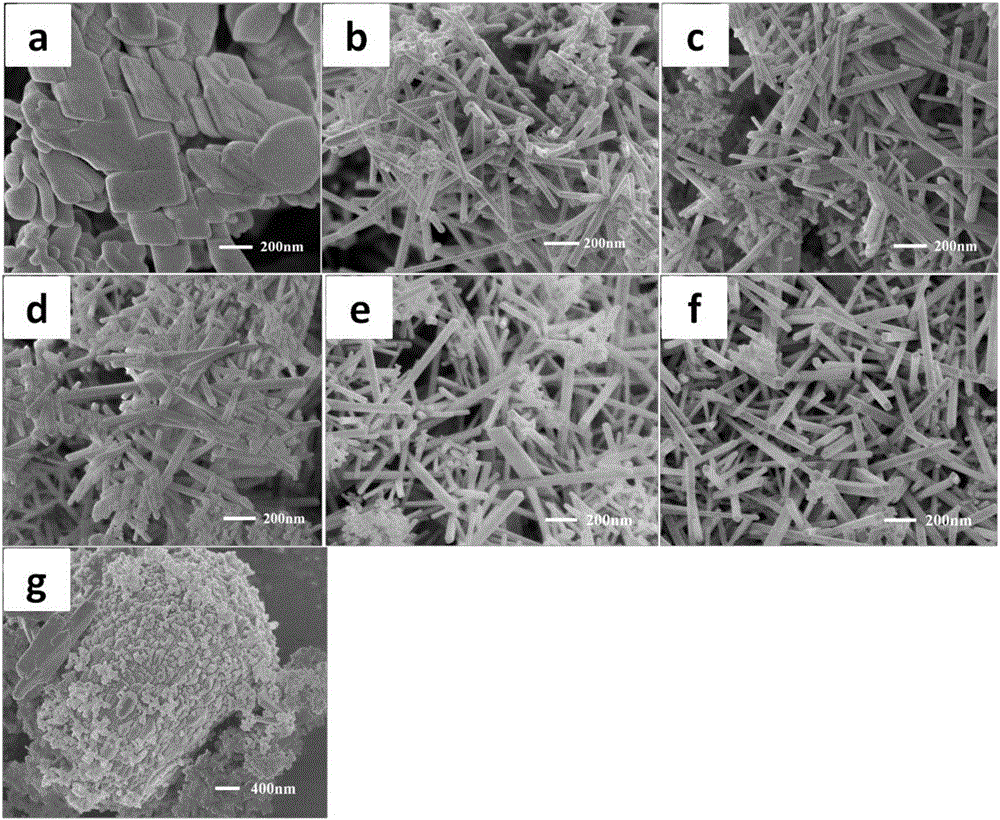

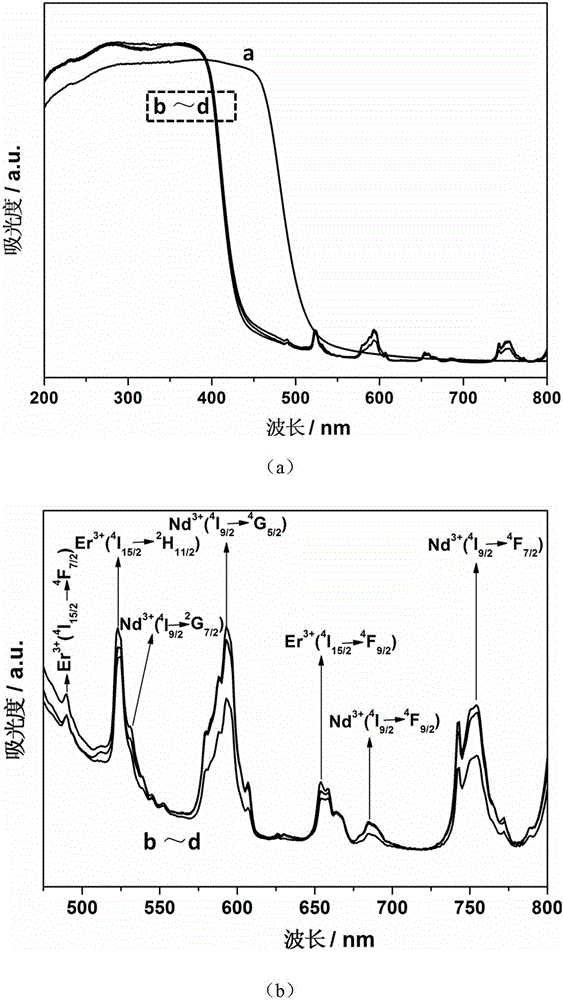

Rare earth co-doped BiVO4 photocatalyst with upconversion characteristic and preparing method and application thereof

A technology of conversion characteristics and photocatalysts, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve unseen problems and improve photocatalytic activity , excellent degradation activity, and the effect of improving the efficiency of photocatalytic reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, and stirred on a magnetic stirrer for 25 minutes to prepare a mother solution A with a concentration of 0.4mol / L; 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer at 90°C for 25 minutes, and prepare mother liquor B with a concentration of 0.4mol / L;

[0032] Step 2: Add mother liquor B to mother liquor A according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 20 minutes to obtain a mixed liquor; then use NaOH solution with a concentration of 5mol / L at 0.5mL / min Add it dropwise into the mixture at a speed of 100°C, adjust the pH value of the mixture to 8, and then stir on a magnetic stirrer for 20 minutes;

[0033] Step 3: Add Nd(NO 3 ) 3 ·6H 2 O was added to the mixed solution after adjusting the pH value, magnetically stirred for 30min, and then Er(NO 3 ) 3 ·6H 2 O, magnetically stirred for 30min, and was prepared as a precursor solution, w...

Embodiment 2

[0037] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, and stirred on a magnetic stirrer for 25 minutes to prepare a mother solution A with a concentration of 0.4mol / L; 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer at 90°C for 25 minutes, and prepare mother liquor B with a concentration of 0.4mol / L;

[0038] Step 2: Add mother liquor B to mother liquor A according to the molar ratio of Bi and V of 1:1, and stir on a magnetic stirrer for 20 minutes to obtain a mixed liquor; then use NaOH solution with a concentration of 5mol / L at 0.5mL / min Add it dropwise to the mixed solution, adjust the pH value of the mixed solution to 8, and stir on a magnetic stirrer for 20 minutes;

[0039] Step 3: Add Nd(NO 3 ) 3 ·6H 2 O was added to the mixed solution after adjusting the pH value, stirred by magnetic force for 30min, and then Er(NO 3 ) 3 ·6H 2 O was then added to the mixture, and stirred magnetically for 30 minutes to prepare a ...

Embodiment 3

[0043] Step 1: Bi(NO 3 ) 3 ·5H 2 O was dissolved in deionized water, and stirred on a magnetic stirrer for 25 minutes to prepare a mother solution A with a concentration of 0.4mol / L; 4 VO 3 Dissolve in deionized water at 100°C, heat and stir on a magnetic stirrer at 90°C for 25 minutes, and prepare mother liquor B with a concentration of 0.4mol / L;

[0044] Step 2: Add mother liquor B to mother liquor A according to the molar ratio of Bi and V of 1:1, stir on a magnetic stirrer for 20 minutes to obtain a mixed liquor; Add it dropwise to the mixed solution, adjust the pH value of the mixed solution to 8, and stir on a magnetic stirrer for 20 minutes;

[0045] Step 3: Add Nd(NO 3 ) 3 ·6H 2 O was added to the mixed solution after adjusting the pH value, stirred by magnetic force for 30min, and then Er(NO 3 ) 3 ·6H 2 O was then added to the mixture, and magnetically stirred for 30 minutes to prepare a precursor solution, wherein the molar ratio of Nd to Bi was 6.38:100, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com