Mixing material conveying device of pneumatic fertilization device

A technology of fertilization device and feeder, which is applied in the direction of spraying device, liquid spraying device, etc., can solve the problems of not having liquid fertilizer spraying function, complex structure, uneven fertilization, etc., and achieve simple structure, high fertilization efficiency, and fertilization uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

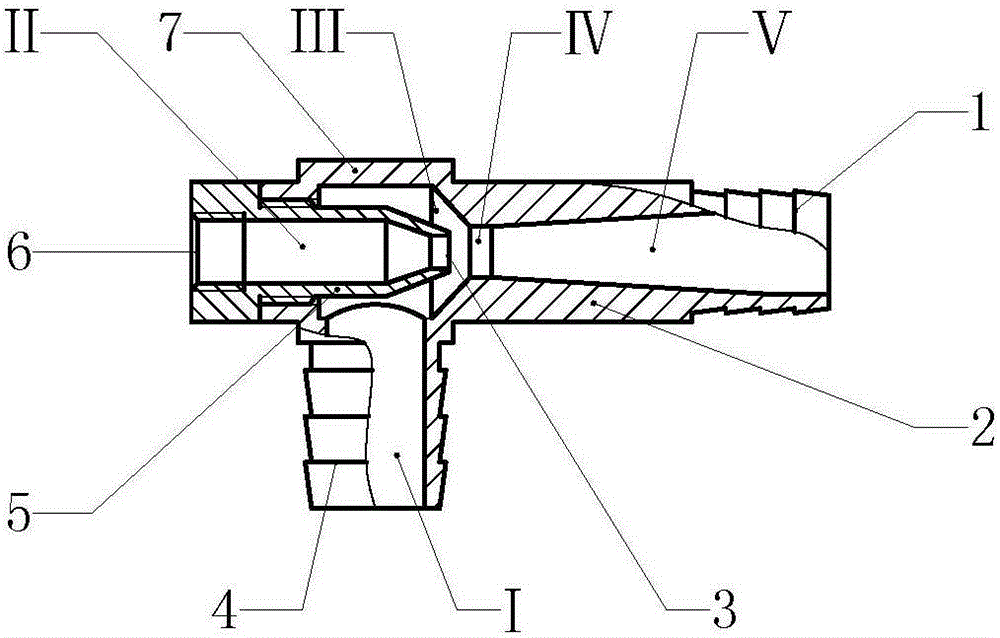

[0013] Example 1 attached figure 1 In the shown embodiment, a mixing feeder of a pneumatic fertilization device is composed of a mixing body 7, a nozzle 2 and a pneumatic nozzle 5, the mixing body 7 and the nozzle 2 are connected as one, and the mixing body 7 is sprayed The rear end of the pipe 2, the mixing body 7 is a hollow structure, and the pneumatic nozzle 5 is placed in the inner space of the mixing body 7 from the rear end of the mixing body 7; the inner space of the pneumatic nozzle 5 constitutes the air passage II, and the air passage The rear end of II has a compressed air input interface 6 connected, and the front part of the pneumatic nozzle 5 has a pneumatic nozzle 3. The front part of the pneumatic nozzle 3 is a hollow conical structure that shrinks from the back to the front. Pneumatic channel II, the diameter of the inner space of the air nozzle 3 gradually shrinks from the back to the front; the back space of the nozzle 2 is a conical structure that shrinks...

Embodiment 2

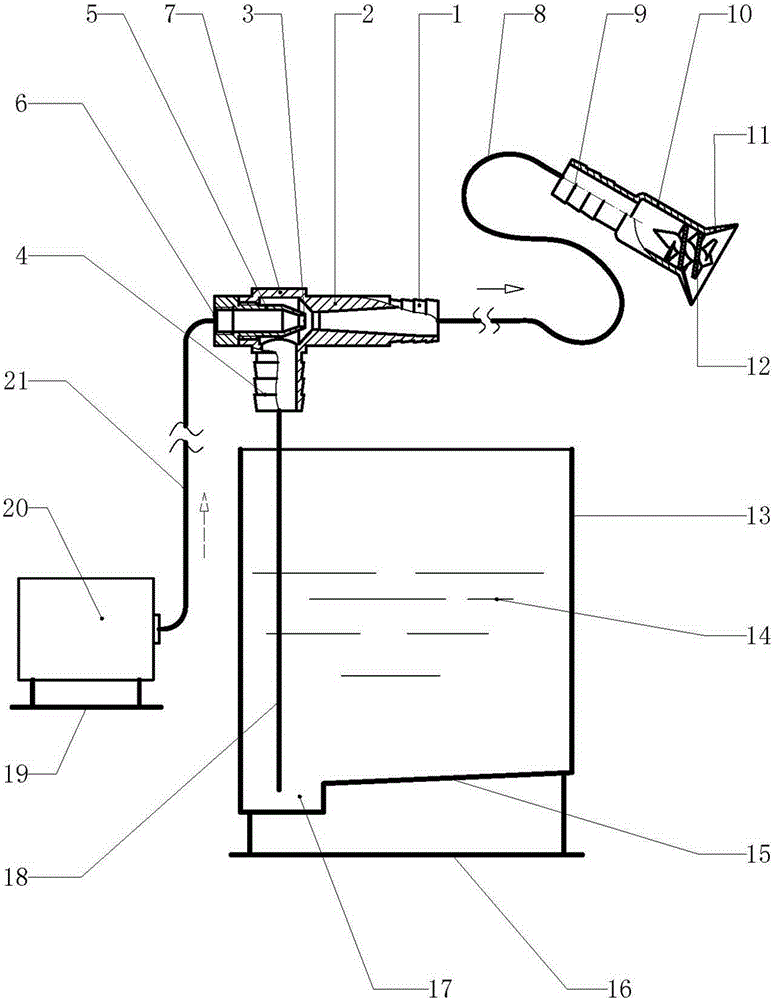

[0015] Example 2 attached figure 2 In the shown embodiment, the mixing feeder of the first embodiment is applied in the pneumatic fertilization device, and the pneumatic fertilization device is composed of an air pump 20, an air delivery pipe 21, a mixing feeder, a suction pipe 18, a feed tank 13, a feeding The pipe 8 and the fertilization nozzle 10 are composed, and the structure of the mixing feeder and the connection mode between the mixing feeder and the peripheral equipment are as described in the first embodiment, and will not be repeated here. Equipped with liquid fertilizer or pesticide in feed pool 13, there is collection pit 17 at the bottom of feed pool 13, and the pool bottom of feed pool 13 is slope-shaped pool bottom, and slope-shaped pool bottom carries out slope towards collection pit 17 direction, and suction pipe 18 The lower end of the lower end stretches into the sump 17, so that the suction pipe 18 can fully absorb the liquid fertilizer or pesticide tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com