Decontaminating cleaning machine

A technology for cleaning machines and materials, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve problems such as unfavorable, ineffective separation, equipment that is not yet separation and removal of impurities, etc. The effect of reducing volume and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

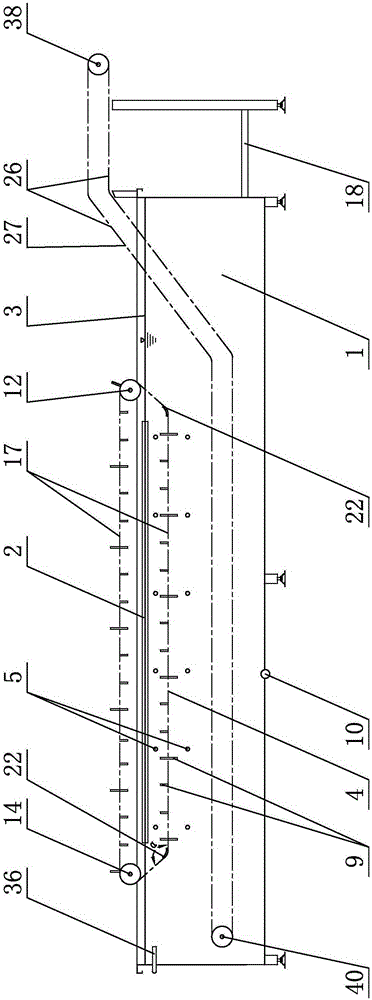

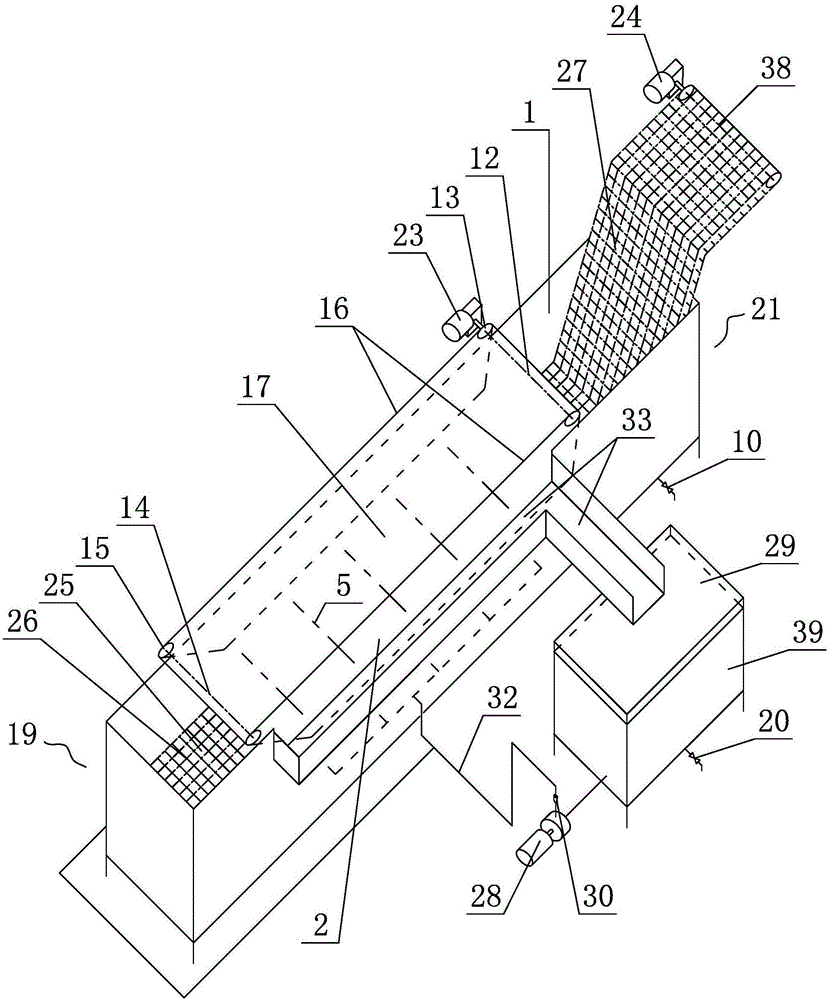

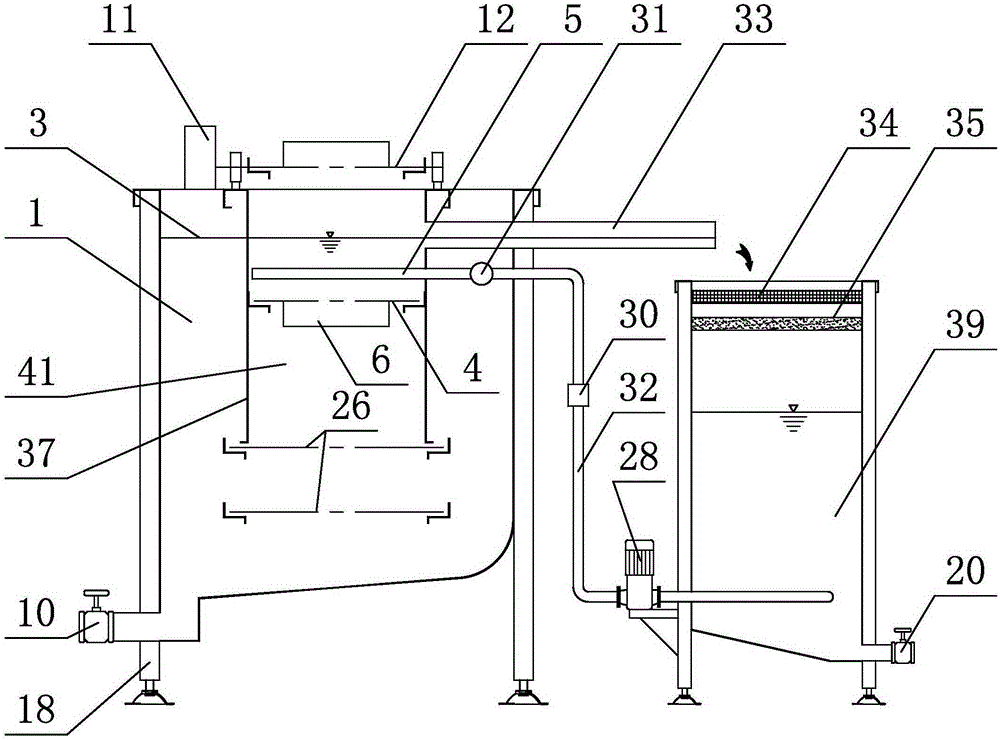

[0037] figure 1 is an embodiment of the present invention, figure 2 and image 3 Except for the addition and subtraction of some structures, it is basically the same as figure 1 similar. The pool 1 is a container that can hold water and materials. The wall of the pool 1 is provided with a water outlet 2. The water outlet 2 is relatively long along the longitudinal direction of the pool 1 so that the water can be evenly discharged, and the water outlet 2 can be connected to the water channel 33 ( figure 2 , image 3 ), the water channel 33 is a ditch or a pipeline, which makes the water flow out after being concentrated. A pressing device 4 and a pushing device 6 are arranged in the pool 1 . The pressing device 4 is a plate or net (such as Figure 4 ), which has holes 7 that are evenly distributed in a network shape and communicated up and down, and the pressing device 4 and the holes 7 are located under the water surface of the pool 1 . Materials can be divided into m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com