Manufacturing process of asymmetric seamless hollow profile

A technology of hollow profile and manufacturing process, which is applied in the direction of metal extrusion dies, etc., can solve the problems of batch supply, no company, cracking, etc., and achieve the effects of reducing the cost of casting ingots, improving surface quality, and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

[0037] The asymmetric seamless hollow profile manufacturing process includes the following steps,

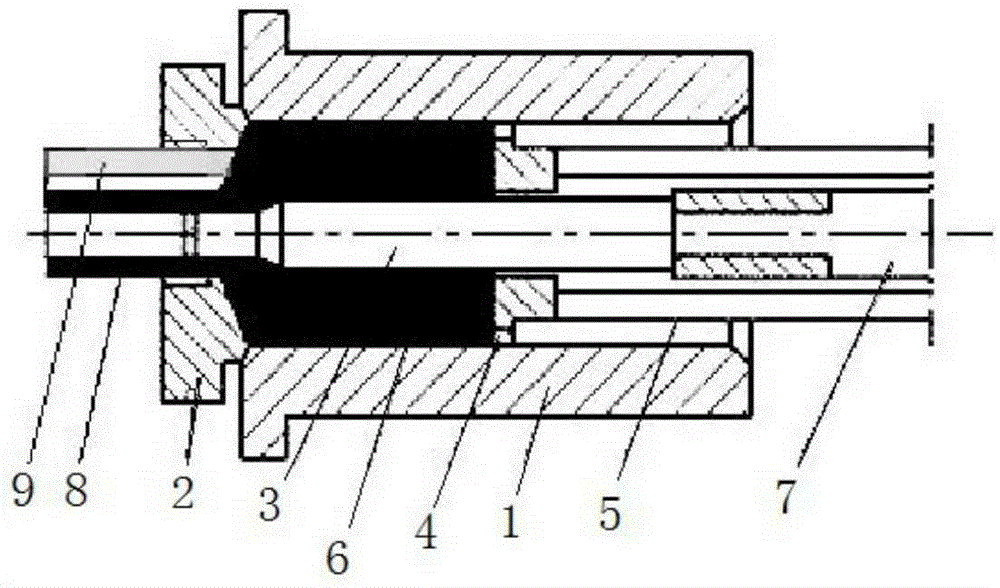

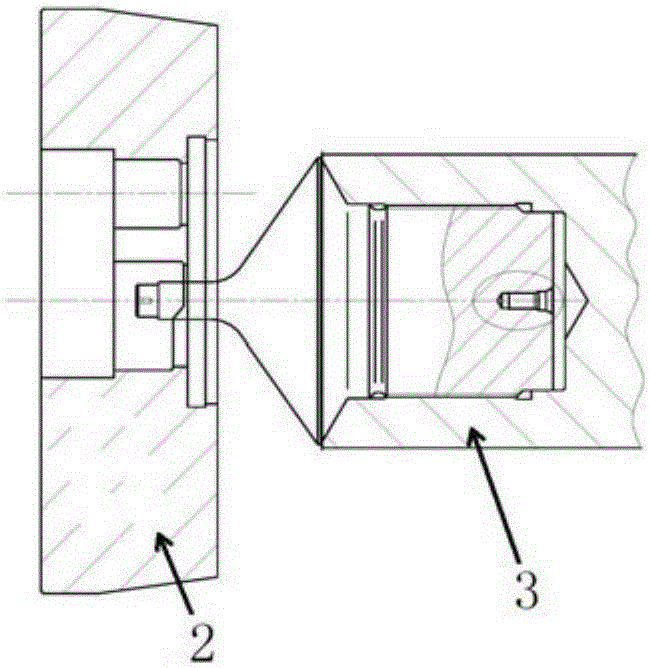

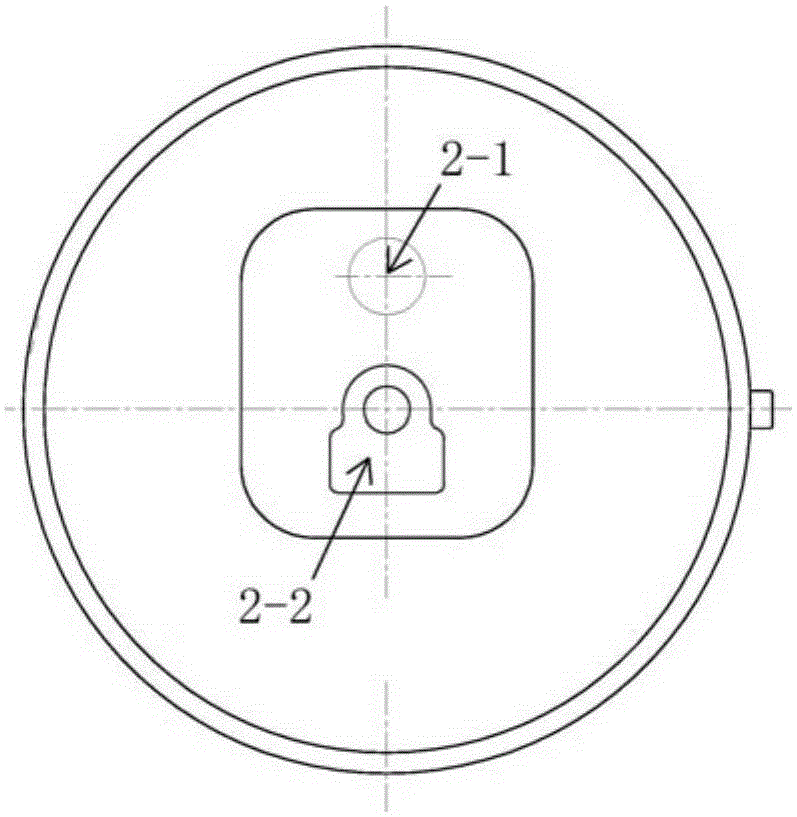

[0038] a. Prefabricated extrusion die; the extrusion die includes an extrusion cylinder 1, an extrusion die 2 is fixed at the front end of the extrusion cylinder 1, and a balance bar extrusion hole 2-1 and a profile extrusion are opened on the extrusion die 2 Holes 2-2 are double holes, a hollow extrusion shaft 5 with an extrusion pad 4 at the front end is provided in the extrusion cylinder 1, an extrusion perforation needle 3 is arranged in the inner cavity of the extrusion shaft 5, and the extrusion perforation needle 3 Installed on the extrusion needle support 7;

[0039] b. Adjustment of the center of the extrusion die; in the cold state, the matching adjustment of the extrusion perforation nee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com