Aluminum alloy thin-wall blade flutter restraining method and passivating method for aluminum alloy thin-wall blade flutter-free cutting tool

A cutting tool, aluminum alloy technology, used in milling cutting inserts, manufacturing tools, metal processing equipment, etc., can solve problems such as damage to the filter system of machine tools, affecting machining accuracy, and contamination of chips

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below with reference to the accompanying drawings and examples.

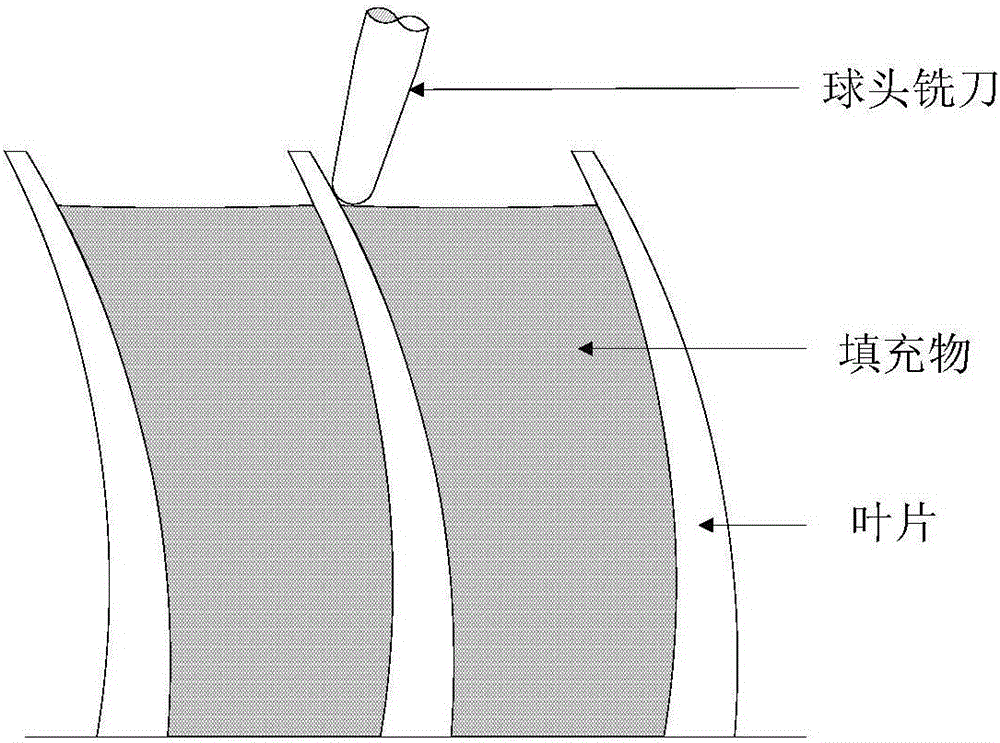

[0024] This embodiment provides a chatter suppression method when cutting aluminum alloy thin-walled blades. This method changes the traditional way of solving the problem of blade chatter. Starting from the cutting tool, a specific passivation method is adopted for the cutting tool. The passivated tool cutting aluminum alloy thin-walled blades can achieve the purpose of suppressing chatter without using auxiliary means such as fillers, and realize chatter-free cutting, thereby effectively ensuring the cutting quality of the blades.

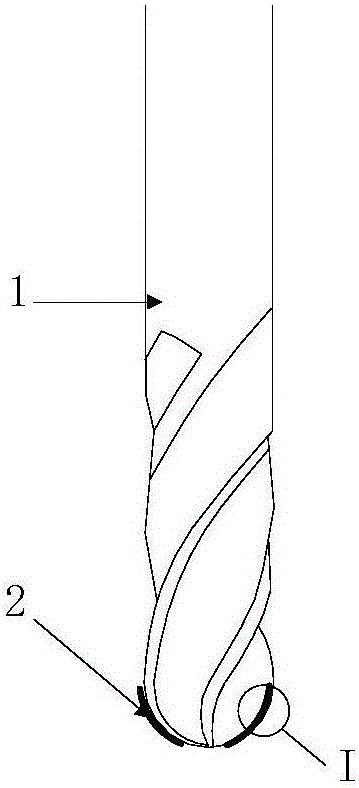

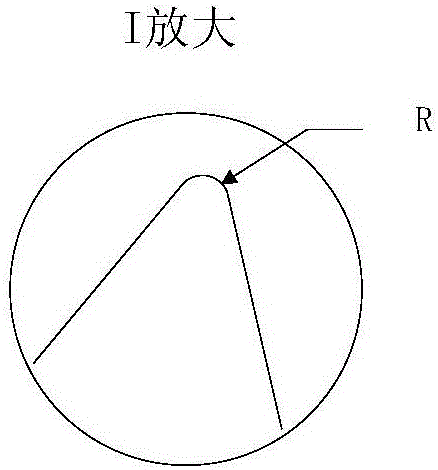

[0025] The idea of the chatter suppression method is: to form a smooth passivation fillet in the range of R10μm by finishing the cutting edge of the tool, which has high wear resistance and plays a role in suppressing regenerative chatter and frictional chatter , to achieve the purpose of chatter-free cutting.

[0026] For...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com