Improved protection door of intelligent numerical control lathe

A technology for CNC lathes and protective doors, which is used in turning equipment, maintenance and safety accessories, time registers, etc., and can solve problems such as the uncertainty of hidden safety hazards of protective doors, complicated correspondence between keys and locks, and long outage intervals. , to achieve the effect of prolonging the effective working time, eliminating the unlocking and matching process, and improving safety and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

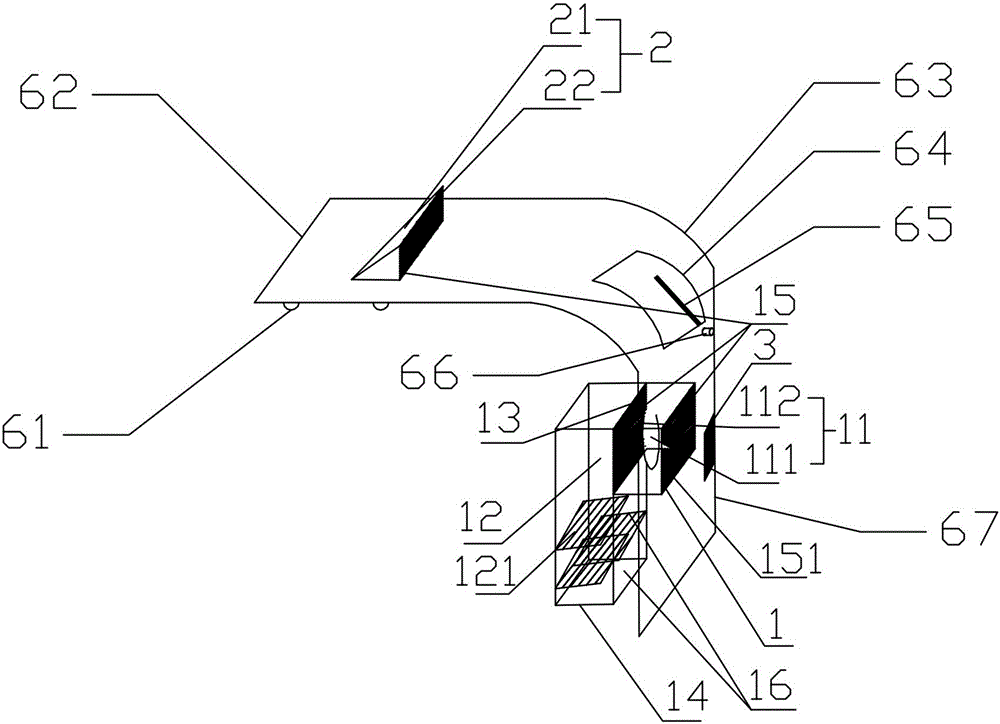

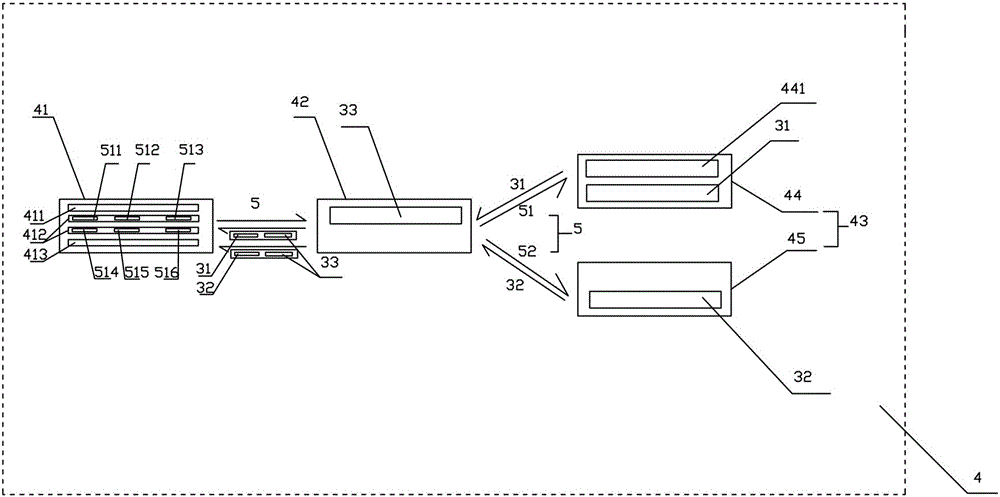

[0018] Such as figure 1 with figure 2 Shown here is an improved protective door for intelligent CNC lathes of the present invention, which includes a horizontal plate 62, a vertical plate 67 and an inclined plate 63. The protective door is arranged on the CNC machine tool and is slidably connected with the protective plate through a sliding groove and a sliding rail. The inner side of the top cover of the protective door is provided with a group of lighting lamps 61, and a window 64 is opened on the protective door. The horizontal plate 62 and the vertical plate 67 are connected by an inclined plate 63. The inclined plate 63 In the shape of an arc, the window 64 is opened on a sloping plate, a curved glass is provided on the window 64, a scraper 65 is provided on the inner side of the curved glass, and one end of the scraper 65 is bent And ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com