Precise cutting fluid cooler

A precision cutting and cooling machine technology, used in grinding/polishing equipment, metal processing mechanical parts, grinding/polishing safety devices, etc., can solve the problems of poor anti-rust effect and difficult dilution, and achieve the effect of protecting the surface of the equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

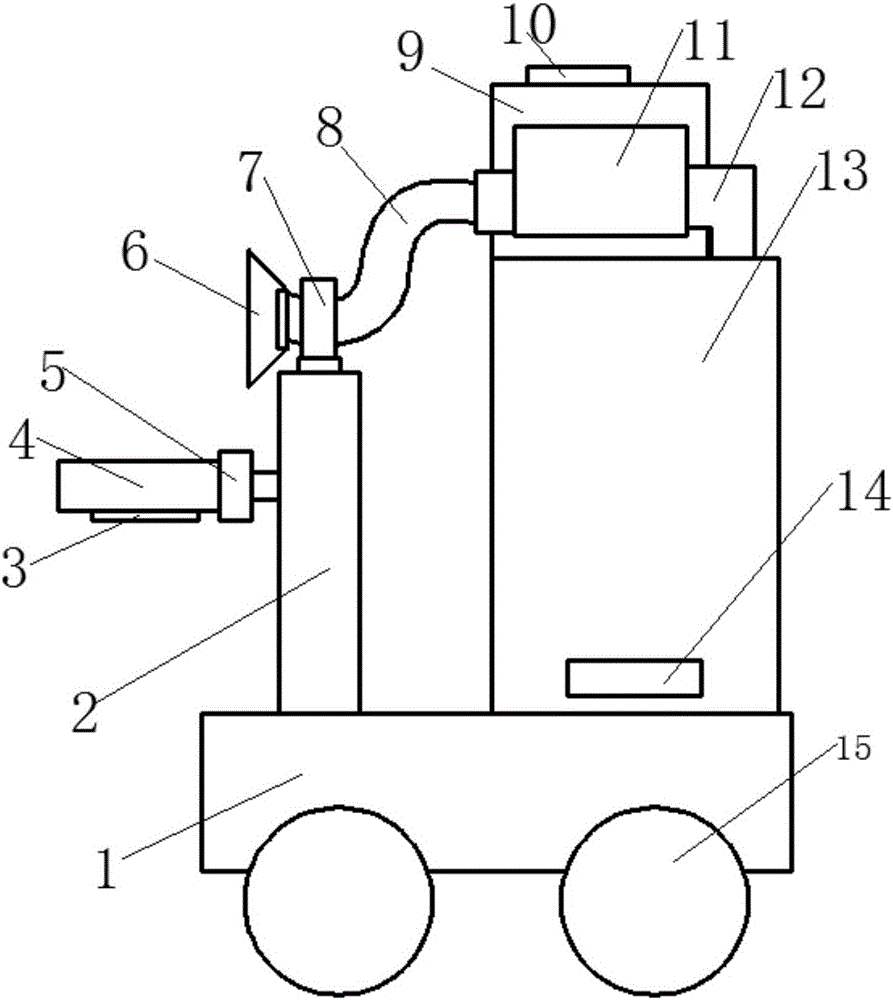

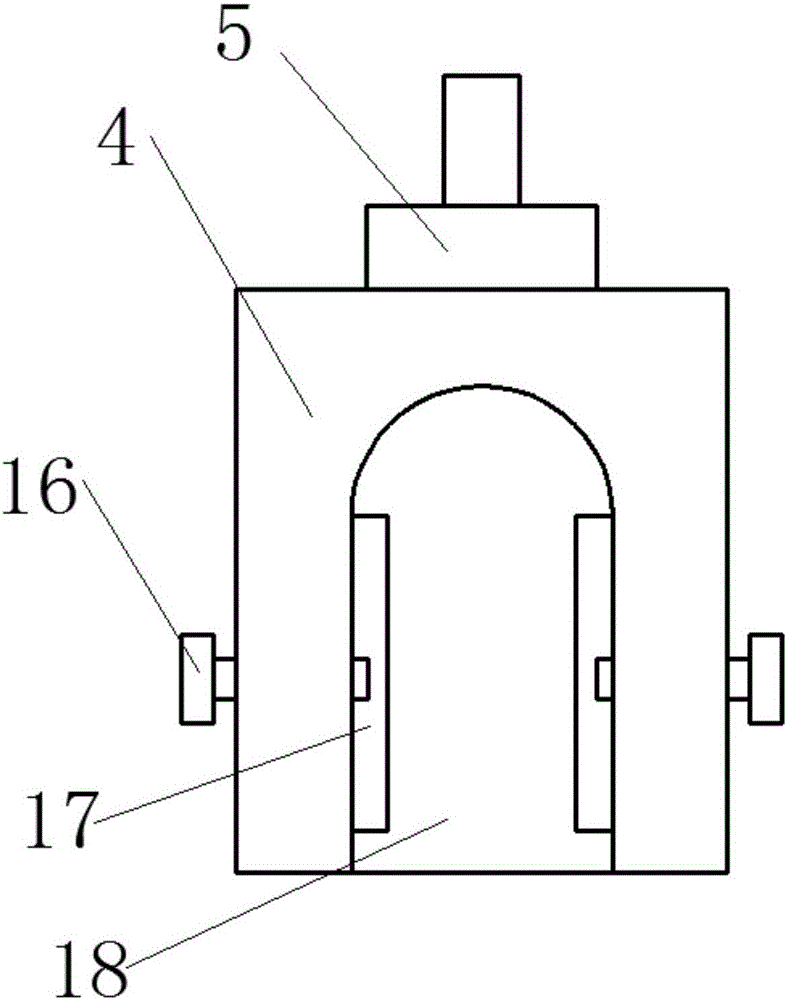

[0014] figure 1 Show the specific implementation of a precision cutting fluid cooler of the present invention: a precision cutting fluid cooler, including a base 1 and a water tank 13, wherein the water tank 13 is located on the base 1, and a spray liquid is provided above the water tank 13 Box 9, the liquid spray box 9 is provided with a liquid storage pipe 11, the upper surface of the liquid spray box 9 is provided with a temperature sensor 10, one side of the liquid spray box 9 is provided with a spray pipe 8, and one end of the liquid storage pipe 11 is connected to the spray pipe 8 are connected, the end of the nozzle 8 is provided with a magnetic nozzle 6, the nozzle 6 is provided with a one-way valve, the spray box 9 is provided with a connecting pump 12 on the opposite side of the nozzle 8, the other end of the liquid storage pipe 11 is connected to the connecting pipe The other end of the pump 12 is connected to the water tank 13, the base 1 is provided with a slide b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com