Treatment method of alkaline pulp waste liquid

A treatment method and technology for waste liquid, which are applied in the fields of waste water treatment during processing, chemical instruments and methods, and multi-stage water/sewage treatment. Liquid pollution, the effect of fast transformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

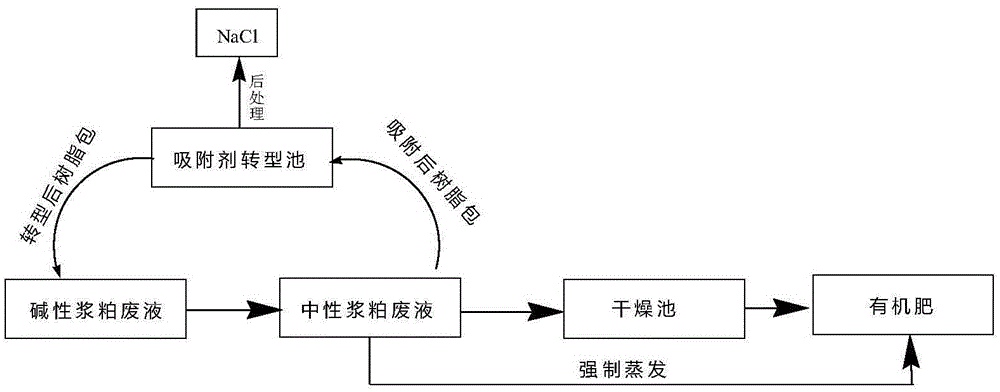

Image

Examples

Embodiment 1

[0031] At room temperature, weigh 10g of ion exchange resin and soak it in 10mL of 12mol / L concentrated hydrochloric acid, take it out after 10min, wash and filter it 3 times with clean water, put it in 50mL pulp waste liquid, take it out after 1min, repeat the operation 10 times, The treated nearly neutral pulp waste liquid is evaporated to dryness to obtain the organic mixture in the waste liquid.

Embodiment 2

[0033] At room temperature, weigh 30g of ion exchange resin and soak it in 30mL12mol / L concentrated hydrochloric acid, take it out after 10min, wash and filter it 3 times with clean water, put it in 50mL pulp waste liquid, take it out after 1min, repeat the operation 4 times, and put the treated The nearly neutral pulp waste liquid is evaporated to dryness to obtain the organic mixture in the waste liquid.

Embodiment 3

[0035] At room temperature, weigh 30g of ion exchange resin and soak it in 30mL12mol / L concentrated hydrochloric acid, take it out after 10min, wash and filter it twice with clean water, put it in 40mL pulp waste liquid, take it out after 1min, repeat the operation 3 times, and put the treated The nearly neutral pulp waste liquid is evaporated to dryness to obtain the organic mixture in the waste liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com