Compound cement grinding agent and method for applying same

A cement grinding aid and composite technology, applied in the field of cement adjuvants, can solve the problems of limited grinding aid capacity, reduced cement strength, rough running, etc., and achieve the effects of reducing dosage, reducing energy consumption, and enhancing cement strength

Inactive Publication Date: 2015-12-16

仇鹏

View PDF0 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] At present, the main components of commercial grinding aids are amine organic substances, polyol organic substances and inorganic salts. This kind of liquid grinding aid compounded by various small molecular substances has many disadvantages when used, and the grinding aid ability has an upper limit. , it is easy to have a wide distribution range of cement product particles, and the product is coarse, resulting in a decrease in cement strength and even affecting the cement strength grade

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment 1、2、3

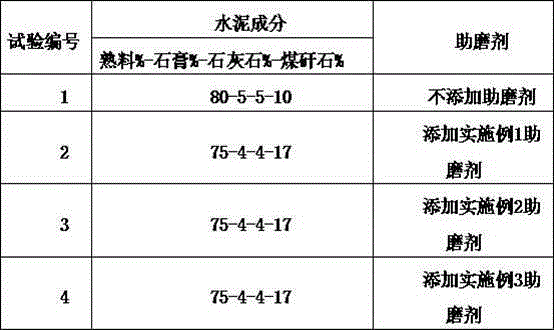

[0020] Table I

[0021]

[0022] The preparation methods of the above examples are well known in the art and will not be described in detail here.

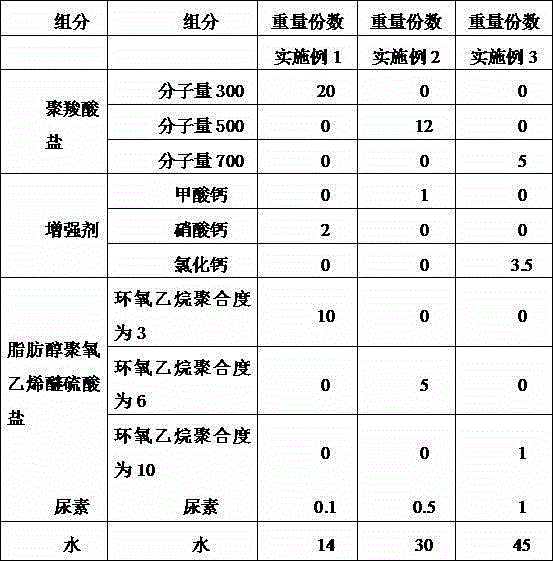

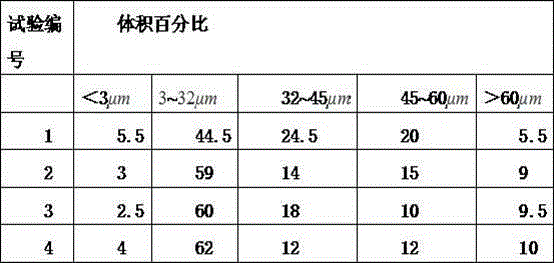

[0023] The cement grinding aid that embodiment 1,2,3 obtains is added in cement and carries out performance test, and the addition amount of grinding aid is 0.2%, and concrete experimental parameter and the concrete composition of cement are shown in Table 2:

[0024] Table II

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to cement auxiliaries, and particularly relates to a compound cement grinding agent and a method for applying the same. The compound cement grinding agent comprises, by weight, 5-20 parts of polycarboxylate, 1-9 parts of reinforcing agents, 1-10 parts of fatty alcohol polyoxyethylene ether sulfate, 0.1-1 part of urea and 14-45 parts of water. The compound cement grinding agent and the method have the advantages that the grinding agent is used in cement processing procedures, accordingly, cement particle diameter adjusting effects can be realized, the strength of cement can be improved, and energy consumption can be reduced in cement production procedures.

Description

technical field [0001] The invention belongs to cement additives, in particular to a composite cement grinding aid, and also relates to its use method. Background technique [0002] The grinding of cement is accomplished by the mutual collision, extrusion and friction of the grinding bodies in the ball mill. When the cement particles are refined, on the one hand, the surface energy of the finely ground cement particles is relatively large, and there is a tendency for the fine particles to automatically agglomerate; on the other hand, if the qualified fine powder cannot be unloaded from the mill in time, it will cause paste balls and forging. Thereby the internal impact of the ball mill is reduced, the grinding energy is consumed, and the grinding efficiency of the ball mill is seriously affected. [0003] The particle size of cement particles is 3~32 μm Contributes greatly to the strength of cement, and the particle size of cement particles is 3~32 μm The more, the greate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/28C04B103/52

Inventor 仇鹏

Owner 仇鹏

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com