Wear resistant ceramic cam ring and preparation method thereof

A cam ring and wear-resistant technology, applied in the field of wear-resistant ceramic cam ring and its preparation, can solve the problems of long production cycle of hot die casting, low forming dimensional accuracy, many manual operations, etc., so as to improve labor efficiency and improve The effect of service life and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

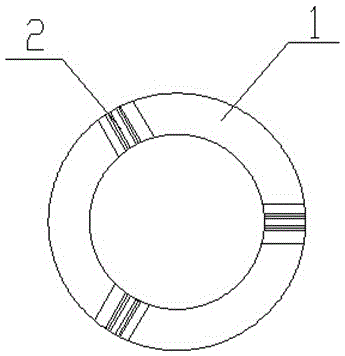

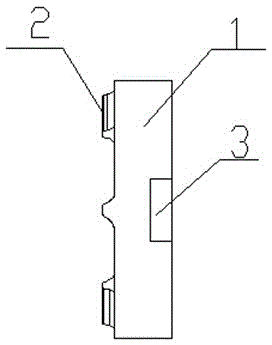

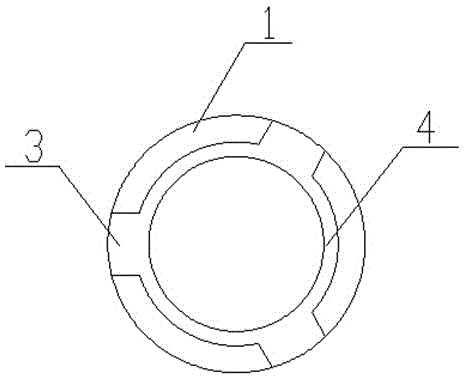

[0021] Such as figure 1 A wear-resistant ceramic cam ring is shown, whose raw material is alumina ceramics with an alumina content of 85%. The ceramic cam ring includes a cam ring body (1), and the cam ring body (1) is There are three protruding points (2) at equal intervals, and the three protruding points (2) correspond to three grooves (3) on the other side of the cam ring body (1), and the three grooves (3) pass through A ring-shaped groove (4) is connected, and the preparation steps of the wear-resistant ceramic cam ring are as follows:

[0022] 1) Feed material: Mix ceramic powder and polymethyl methacrylate (PMMA) + polyethylene oxide (PEO) composite binder system at a ratio of 88wt%: 12wt% to form powder injection molding feed;

[0023] 2) Injection molding: the injection molding mixture is installed on the injection molding machine with a screw abrasive tool and injected to obtain a green body. The injection temperature is between 175°C, and the molded body is obtain...

Embodiment 2

[0027] Such as figure 1 Shown is a wear-resistant ceramic cam ring whose raw material is zirconia ceramics with a zirconia content of 90%. The ceramic cam ring includes a cam ring body (1), and the cam ring body (1) is superior to There are three convex points (2) at intervals, and the three convex points (2) correspond to three grooves (3) on the other side of the cam ring body (1), and the three grooves (3) pass through a The annular grooves (4) are connected, and the preparation steps of the wear-resistant ceramic cam ring are as follows:

[0028] 1) Feed: Mix ceramic powder and polymethyl methacrylate (PMMA) + polyethylene oxide (PEO) composite binder system at a ratio of 92wt%: 8wt% to form a powder injection molding feed;

[0029] 2) Injection molding: The injection molding mixture is installed on the injection molding machine with a screw abrasive tool and injected to obtain a green body. The injection temperature is between 180°C, and the molded body is obtained withi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com