Environment-friendly polyurethane foaming mixed material for tyre and preparation method thereof

A polyurethane and environmentally friendly technology, applied in the field of polyurethane, can solve the problems of thin skin and poor performance, and achieve the effect of bright surface, good skinning and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

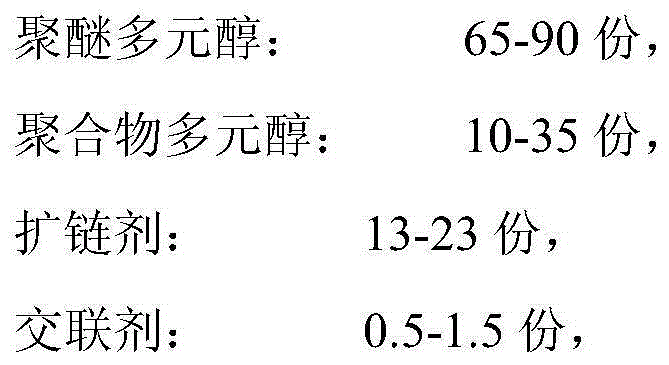

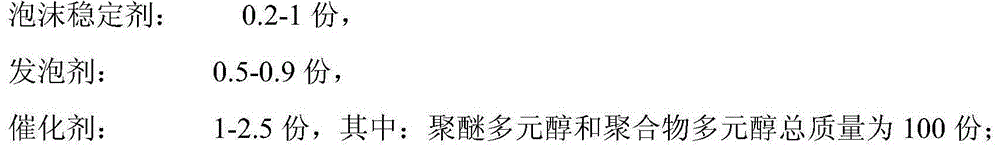

Method used

Image

Examples

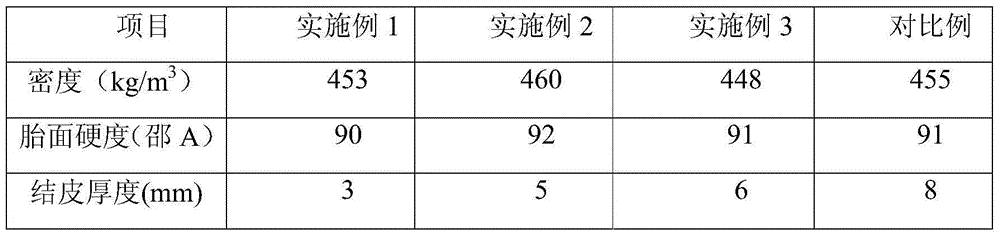

Embodiment 1

[0036] Component A: Weigh 90Kg of EP-330NG and POP36 / 2810Kg and put them into the reactor for stirring, then add 7Kg of 1,4-butanediol, 13Kg of ethylene glycol, 1.0kg of glycerin, A-331.5Kg, AK-77030.2Kg , DC-1930.2Kg, water 0.5Kg. Stir at 30°C for 1 hour, mix thoroughly and evenly, store in a sealed container, and set aside.

[0037] Component B: Weigh 10Kg of PE-2420 and place it in a kettle, stir and heat up to 100°C, dehydrate and degas under vacuum for 2 hours. Then cool down to 40°C, start stirring and add 30Kg of 4,4'-diphenylmethane diisocyanate, 3Kg of carbodiimide modified MDI, slowly raise the temperature to 85°C, and keep the temperature for 1.5 hours. Stir for 20 minutes, take a sample for inspection, flush N after passing the test 2 Unload, spare.

[0038] When in use, maintain the temperature of materials A and B at 35-40°C, pour components A and B into a dynamic tire mold with a mass ratio of 100:94, mold temperature is 50-55°C, and open the mold in 3 minute...

Embodiment 2

[0040] Component A: Weigh EP360090Kg and POP36 / 2810Kg respectively and put them into the reactor for stirring, then add propylene glycol 14Kg, ethylene glycol 6Kg, diethanolamine 0.5kg, A-10.5kg, A-33:0.8Kg, CS-120.05kg , AK-77030.2Kg, DC60700.2Kg, water 0.6Kg. Stir at 30°C for 2 hours, mix thoroughly and evenly, store in a sealed container, and set aside.

[0041] Component B: Weigh CMA-24415Kg and place it in a kettle, stir and heat up to 90°C, dehydrate and degas under vacuum for 3 hours. Then cool down to 40°C, start stirring and add 30Kg of 4,4'-diphenylmethane diisocyanate, 10Kg of carbodiimide modified MDI, slowly raise the temperature to 85°C, and keep the temperature for 1.5 hours. Stir for 20 minutes, take a sample for inspection, flush N after passing the test 2 Unload, spare.

[0042] When in use, maintain the temperature of materials A and B at 35-40°C, pour components A and B into a dynamic tire mold with a mass ratio of 100:92, mold temperature is 50-55°C, an...

Embodiment 3

[0044] Component A: Weigh EP-330NG80Kg and POP93 / 2820Kg respectively and put them into the reactor for stirring, then add 1,4-butanediol 7Kg, ethylene glycol 6Kg, triethanolamine 1.5kg, A-331.5Kg, AK-77030.3 Kg, DC60700.3Kg, water 0.5Kg. Stir at 30°C for 1 hour, mix thoroughly and evenly, store in a sealed container, and set aside.

[0045] Component B: Weigh 10Kg of PE-2420 and place it in a kettle, stir and heat up to 95°C, dehydrate and degas under vacuum for 2.5 hours. Then cool down to 40°C, start stirring and add 30Kg of 4,4'-diphenylmethane diisocyanate, 10Kg of carbodiimide-modified MDI, slowly raise the temperature to 82°C, and keep warm for 1.5 hours. Stir for 20 minutes, take a sample for inspection, flush N after passing the test2 Unload, spare.

[0046] When in use, maintain the temperature of materials A and B at 35-40°C, pour components A and B into a dynamic tire mold with a mass ratio of 100:93, mold temperature 50-55°C, and open the mold in 3 minutes , aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com