Multifunctional additive, preparation method of multifunctional additive and application of multifunctional additive in coal mine reinforcement materials

A reinforcing material and multi-functional technology, applied in chemical instruments and methods, drilling composition, etc., can solve the problems of material inhomogeneity, loss of material mechanical properties, layering of reinforcing materials affecting construction, etc., to improve safety , the effect of reducing the reaction temperature and improving the toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

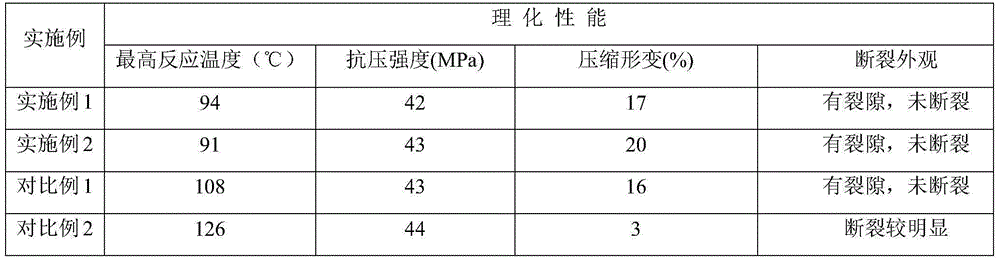

[0021] Accurately weigh 5% tributyl phosphate, 40% dibutyl phthalate, 20% methyl oleate and 35% methyl linoleate, stir with a stirrer for 10 minutes, mix evenly, that is multi-functional additive . The additive is mixed with the isocyanate component (polymeric MDI, the specific brand is PM-200) of the coal mine reinforcement material at a weight ratio of 3:7, stirred and mixed evenly to form the A component; the catalyst triethanolamine (TEA), bismorpholine di Ethyl ether (DMDEE) and auxiliary agent ethylene glycol and 50Be ° liquid sodium silicate stirring (wherein catalyst triethanolamine (TEA), bismorpholine diethyl ether (DMDEE) and auxiliary agent ethylene glycol are all a small amount, mainly Stir for liquid sodium silicate) and mix well to form component B. The low exothermic reinforcement material can be prepared by mixing component A and component B in equal volume. And investigate the maximum reaction temperature, compressive strength and compressive deformation of...

Embodiment 2

[0024] Accurately weigh 8% tributyl phosphate, 20% dibutyl phthalate, 40% methyl oleate and 32% methyl linoleate, stir with a stirrer for 10 minutes, and mix well, that is, a multifunctional additive . Mix the additive with the isocyanate component of the coal mine reinforcement material at a ratio of 3:7, stir and mix evenly to form the A component; mix the A component with the catalyst-containing liquid sodium silicate B component in equal volume to obtain about 200 ml of low exothermic reinforcement material. And investigate the maximum reaction temperature, compressive strength and compressive deformation of the reinforced material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com