Method and system for recycling bamboo dust and application of obtained product

A technology of bamboo chips and bamboo oil, which is applied in the preparation of liquid hydrocarbon mixtures, biofuels, fat production, etc., can solve the problems of long distillation time, long preparation time, burning, etc., and achieve the functions of promoting cell metabolism and cell regeneration , the effect of strong adsorption and decomposition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The detailed structure of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

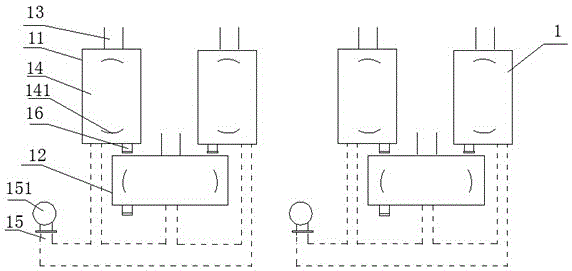

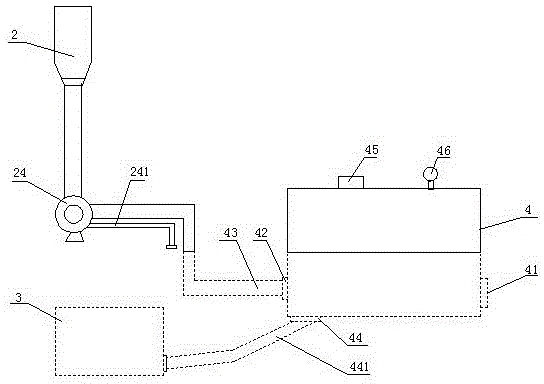

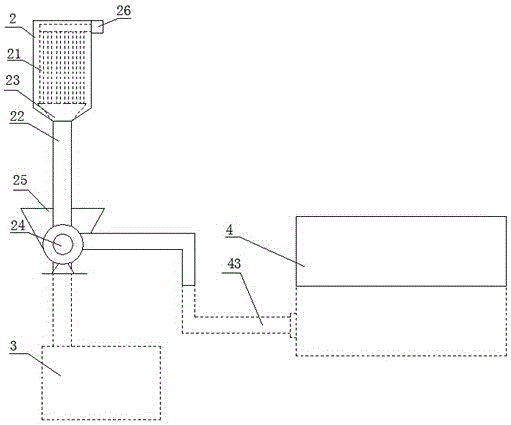

[0043] A bamboo chip recycling system includes a combustion chamber, a cooling tower 2, an oil storage tank 3 and an air storage tank 4.

[0044] Specifically, such as figure 1As shown: the combustion chamber includes six rows of underground combustion chambers 1, and the number of each row of underground combustion chambers 1 is three; the front side of each row of underground combustion chambers 1 is provided with an air duct 15, and the air duct 15 protrudes from the ground to the ground ; The underground part of the air duct 15 is connected with the air inlet of each row of the underground combustion chamber 1 . The three underground combustion chambers 1 include two vertical underground combustion chambers 11 and one horizontal underground combustion chamber 12 . The vertical underground combustion chambers 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com