Improved 42 CrMo steel and method for machining knuckles through improved 42 CrMo steel

A processing method and steering knuckle technology, applied in the field of steering knuckle processing, can solve the problems of scrapping cracked workpieces, products are easy to crack, increase costs, etc., and achieve the effects of reducing scrap rate, improving quality stability, and reducing failure rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be described in further detail below in conjunction with specific examples, and the implementation scope of the present invention is not limited thereto.

[0012] The chemical composition (mass percentage) of the improved 42CrMo steel in this embodiment is C: 0.37% to 0.43%; S: 0.01% to 0.030%; Si: 0.15% to 0.35%; Mn0.6% to 0.9%; Cr0 .95%~1.2%; Mo0.16%~0.25%, the rest is Fe.

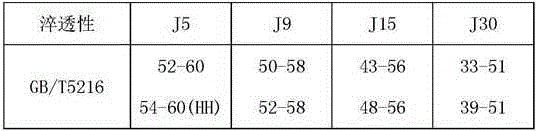

[0013] Compared with the 42CrMo steel (and other standards) in the existing national standard, the content of non-metallic elements is at the lower limit of the national standard, while the content of strong hardenability alloying elements (Cr, Mo) is at the upper limit of the national standard, and its scope has been reduced . For the round steel of this material, after quenching, the hardenability bandwidth (HRC) is: J5: 52-60; J9: 50-58; J15: 47-55; J30: 35-48, and the quenching method is as follows: section of the quenching method. Compared with the national stand...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com