Copper zinc alloy electroplating liquid and electroplating method thereof

An alloy electroplating solution, copper-zinc technology, applied in the field of electroplating solution, can solve the problems of poor stability, poor corrosion resistance of the coating, difficulty in obtaining the coating, etc., and achieve the effect of good corrosion resistance, good bonding force, and bright and smooth appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

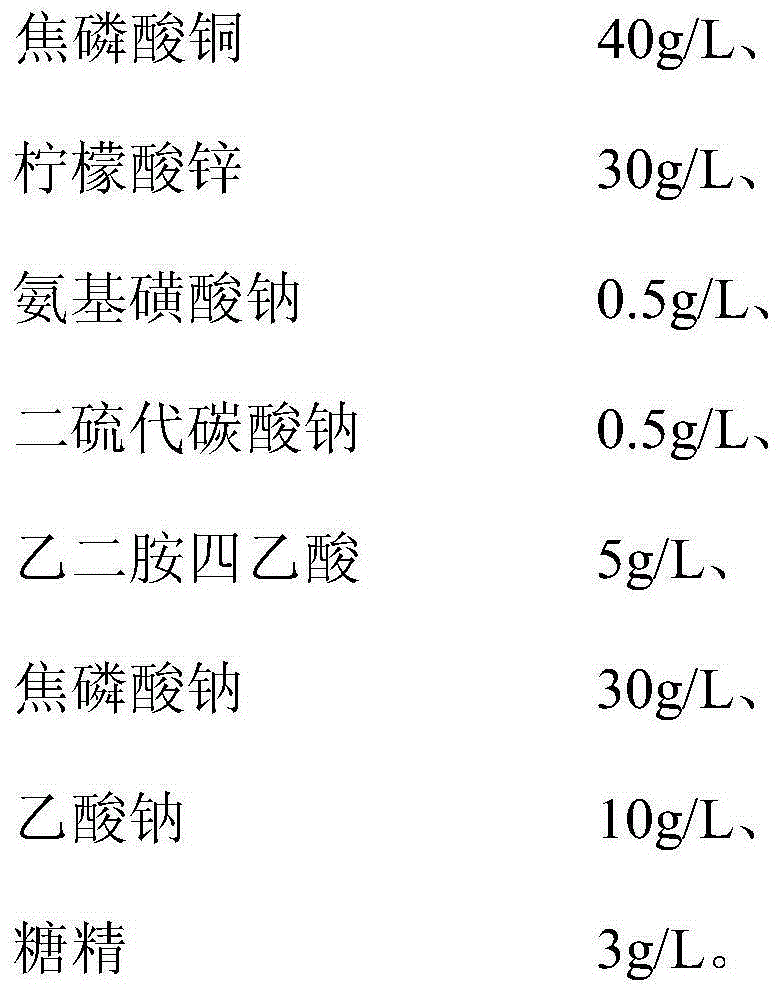

[0020] Embodiment 1: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0021]

[0022] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0023] Configure the above-mentioned copper-zinc alloy electroplating solution, with the metal substrate as the cathode, graphite as the anode, the distance between the cathode and the anode is 10cm, and the temperature of the copper-zinc alloy electroplating solution is 25°C and the current density is 15mA / cm 2 Under the condition of electroplating for 10 minutes, the coating was obtained.

Embodiment 2

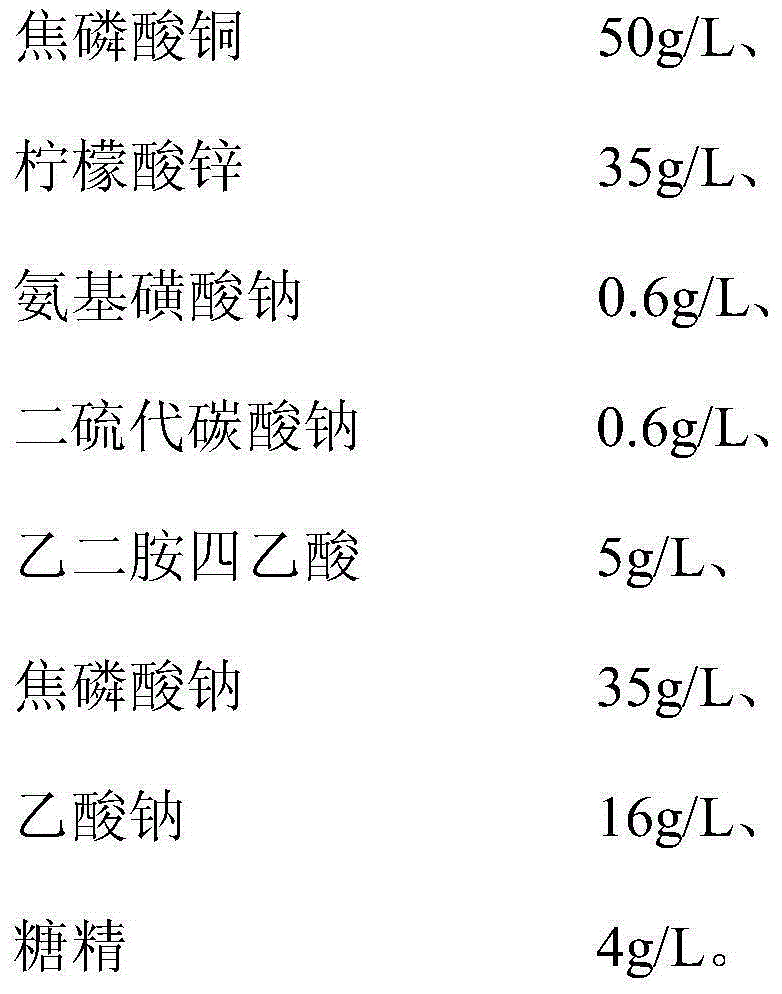

[0024] Embodiment 2: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0025]

[0026] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0027] Configure the above-mentioned copper-zinc alloy electroplating solution, with the metal substrate as the cathode, graphite as the anode, the distance between the cathode and the anode is 10cm, and the temperature of the copper-zinc alloy electroplating solution is 25°C and the current density is 15mA / cm 2 Under the condition of electroplating for 10 minutes, the coating was obtained.

Embodiment 3

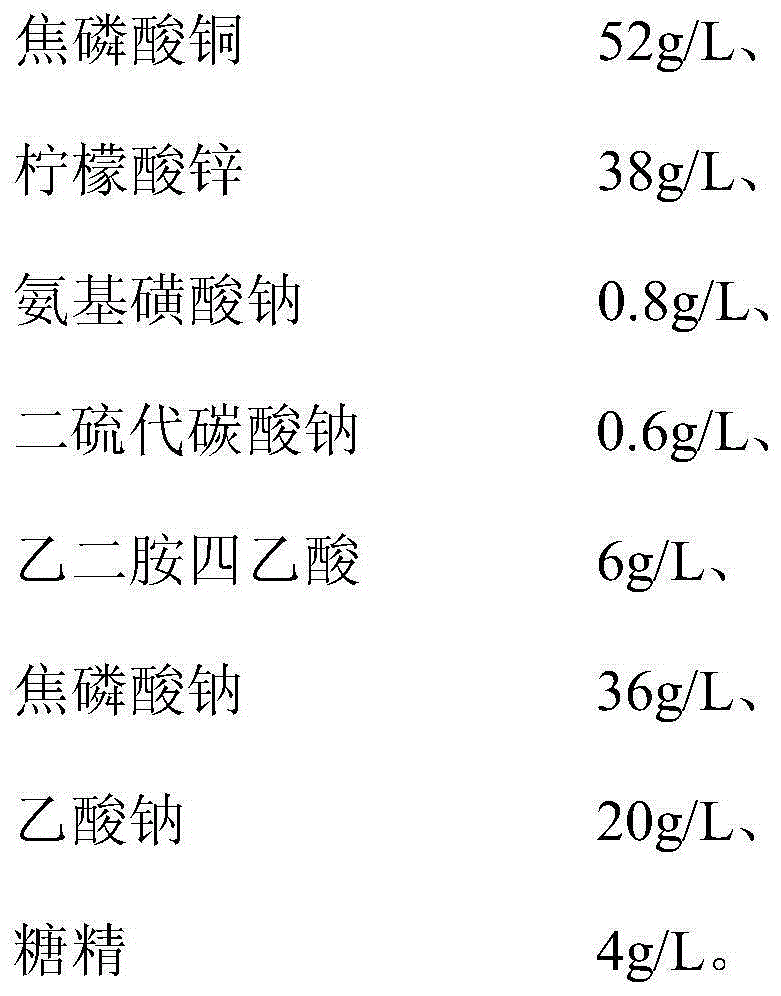

[0028] Embodiment 3: the copper-zinc alloy electroplating solution of the present embodiment comprises following components:

[0029]

[0030] Use above-mentioned copper-zinc alloy electroplating solution electroplating method as follows:

[0031] Configure the above-mentioned copper-zinc alloy electroplating solution, with the metal substrate as the cathode, graphite as the anode, the distance between the cathode and the anode is 10cm, and the temperature of the copper-zinc alloy electroplating solution is 25°C and the current density is 15mA / cm 2 Under the condition of electroplating for 10 minutes, the coating was obtained.

[0032] The coating obtained by electroplating with the copper-zinc alloy electroplating solution of the invention has no cracks, bright and smooth appearance, good corrosion resistance, and good bonding force between the coating and the base material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com