A kind of water-based coating with high salt spray and high weather resistance and preparation method thereof

A water-based coating, high weather resistance technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problem that a single coating does not meet the requirements of high weather resistance and high salt spray, and achieve smooth and bright appearance, good weather resistance, and good mechanical properties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

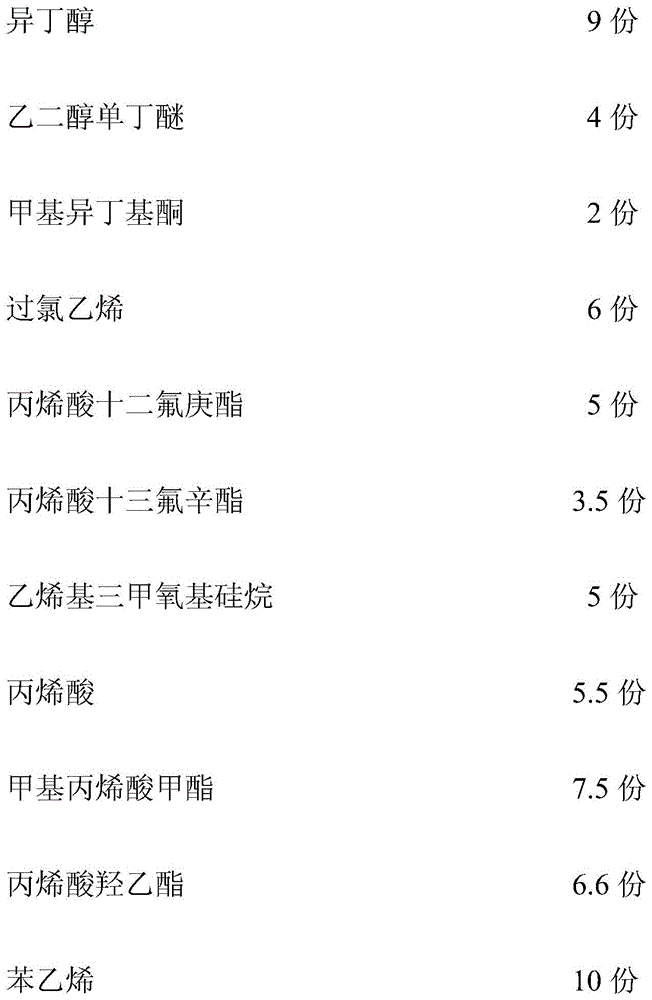

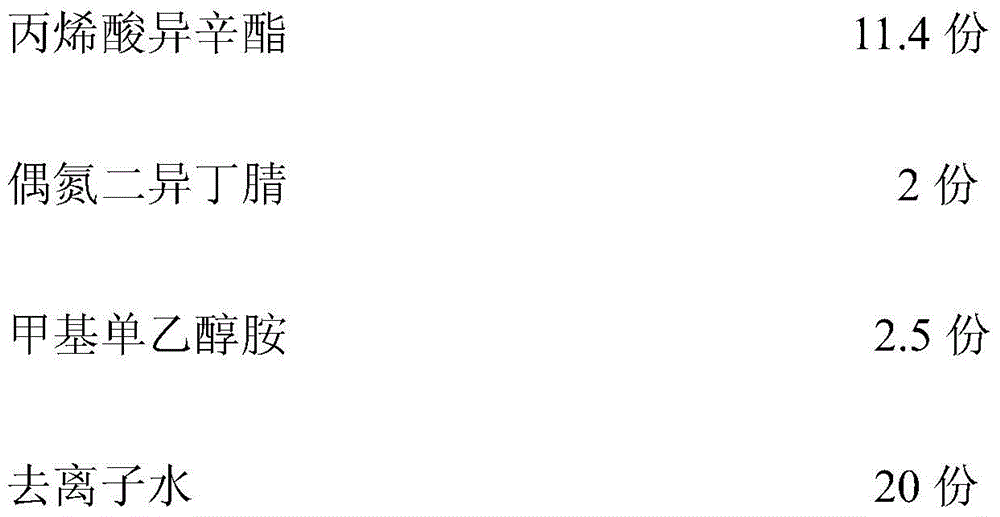

[0024] 1) The formula of the acrylic modified emulsion with high salt spray and high weather resistance with core-shell structure:

[0025]

[0026]

[0027] Mix 6 parts by weight of perchlorethylene, 2 parts by weight of acrylic acid, 2.4 parts by weight of hydroxyethyl acrylate, 5.5 parts by weight of methyl methacrylate, 10 parts by weight of styrene, and 0.8 parts by weight of azobisisobutyronitrile to obtain a mixed solution a, for use;

[0028] 5 parts by weight of dodecafluoroheptyl acrylate, 3.5 parts by weight of trifluorooctyl acrylate, 5 parts by weight of vinyltrimethoxysilane, 3.5 parts by weight of acrylic acid, 4.4 parts by weight of hydroxyethyl acrylate, 2 parts by weight of methacrylic acid Methyl ester, 11.4 parts by weight of isooctyl acrylate, and 0.8 parts by weight of azobisisobutyronitrile were mixed uniformly to obtain mixed liquid b, which was set aside;

[0029] 0.4 parts by weight of azobisisobutyronitrile and 2 parts by weight of methyl isob...

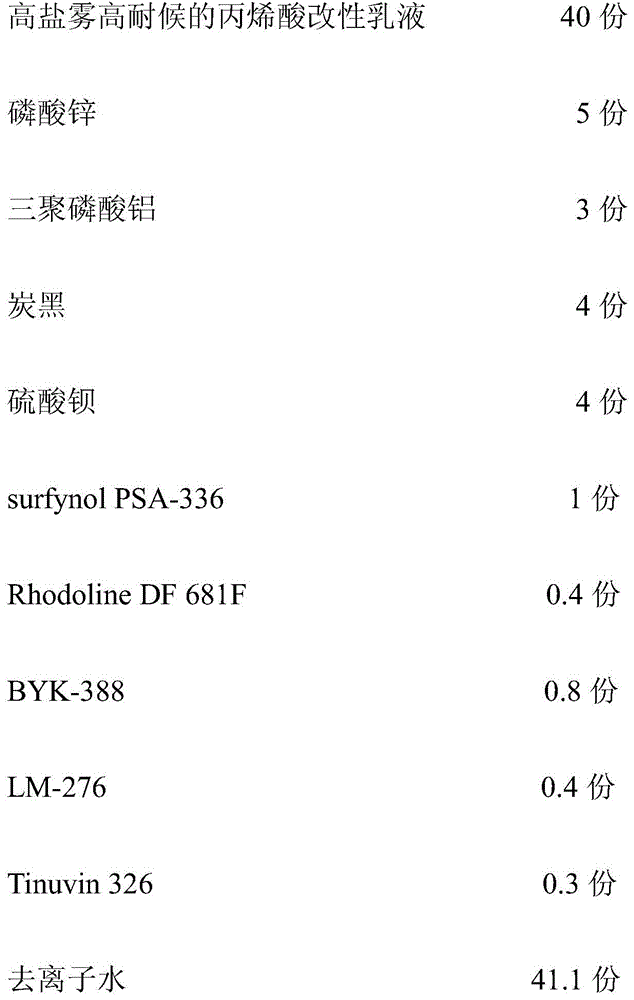

Embodiment 2

[0035]1) The formula of the acrylic modified emulsion with high salt spray and high weather resistance with core-shell structure:

[0036]

[0037] Mix 5 parts by weight of perchlorethylene, 1.5 parts by weight of acrylic acid, 2.2 parts by weight of hydroxyethyl acrylate, 5 parts by weight of methyl methacrylate, 8.6 parts by weight of styrene, and 0.6 parts by weight of azobisisobutyronitrile to obtain a mixed solution a, for use;

[0038] 3.5 parts by weight of dodecafluoroheptyl acrylate, 2.5 parts by weight of trifluorooctyl acrylate, 4 parts by weight of vinyltrimethoxysilane, 3 parts by weight of acrylic acid, 4.1 parts by weight of hydroxyethyl acrylate, 1.5 parts by weight of methacrylic acid Methyl ester, 9.7 parts by weight of isooctyl acrylate, and 0.6 parts by weight of azobisisobutyronitrile were mixed uniformly to obtain mixed solution b, which was set aside;

[0039] Mix 0.3 parts by weight of azobisisobutyronitrile and 3 parts by weight of methyl isobutyl ...

Embodiment 3

[0046] 1) The formula of the acrylic modified emulsion with high salt spray and high weather resistance with core-shell structure:

[0047]

[0048]

[0049] Mix 4 parts by weight of perchlorethylene, 1 part by weight of acrylic acid, 2 parts by weight of hydroxyethyl acrylate, 4.5 parts by weight of methyl methacrylate, 7.2 parts by weight of styrene, and 0.4 parts by weight of azobisisobutyronitrile to obtain a mixed solution a, for use;

[0050] 2 parts by weight of dodecafluoroheptyl acrylate, 1.5 parts by weight of trifluorooctyl acrylate, 3 parts by weight of vinyltrimethoxysilane, 2.5 parts by weight of acrylic acid, 3.8 parts by weight of hydroxyethyl acrylate, 1 part by weight of methacrylic acid Methyl ester, 8 parts by weight of isooctyl acrylate, and 0.4 parts by weight of azobisisobutyronitrile are mixed uniformly to obtain mixed liquid b, which is set aside;

[0051] Mix 0.2 parts by weight of azobisisobutyronitrile and 4 parts by weight of methyl isobutyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| gloss loss | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

| gloss loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com