Filling method of composite refrigerant for MRC refrigeration cycle

A refrigeration cycle and composite refrigerant technology, applied in refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of extremely high requirements and complexity of operators, and achieve the effect of simplifying filling steps, equipment optimization, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

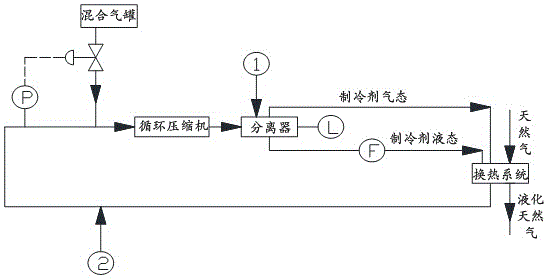

[0040] The working process of the MRC refrigeration cycle, such as figure 1 shown, including the following steps:

[0041] (1) After being pressurized by the circulating compressor, the refrigerant cools down and enters the separator, where it is separated into liquid and gaseous states;

[0042] (2) The separated liquid and gas enter the heat exchange system to provide cooling capacity;

[0043] (3) The refrigerant that has passed through the heat exchange system returns to the inlet of the circulating compressor for pressurization.

[0044] The composition and design ratio of the refrigerant in the MRC refrigeration cycle in this embodiment are: 9.5% nitrogen, 18.5% methane, 29% propane, 13% pentane, and 30% ethylene; the above ratios are expressed in molar percentages.

[0045] When the composite refrigerant is filled with refrigerant, it is composed of liquid refrigerant and gaseous refrigerant. In this embodiment, the liquid refrigerant is composed of propane, pentane a...

Embodiment 2

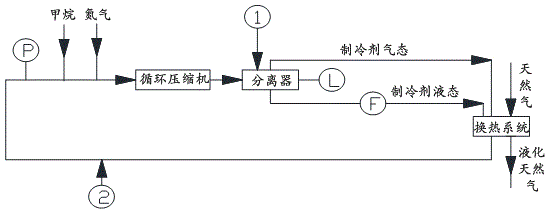

[0053] The difference between this embodiment and Embodiment 1 is that in this embodiment, nitrogen and methane are respectively filled into the inlet of the compressor, as figure 2 shown.

[0054] The specific filling process of this composite refrigerant in the present embodiment is as follows:

[0055] During the refrigeration cycle, the flow rate of the liquid refrigerant is fixed according to the operating load, and the detection point of the flow rate of the liquid refrigerant is located at point F.

[0056] When the refrigerant leaks during the refrigeration cycle, the inlet pressure of the circulating compressor at point P drops. When the pressure at point P drops to a certain level, methane and nitrogen are added to the refrigeration cycle system according to the calculated replenishment amount.

[0057] At the same time, when the refrigerant leaks during the refrigeration cycle, the liquid level of the separator at point L drops. At this time, the liquid refrigeran...

Embodiment 3

[0060] The difference between this embodiment and Embodiment 1 is that in this embodiment, the liquid refrigerant and the gaseous refrigerant are mixed and filled into the mixing tank, and then filled into the MRC refrigeration cycle from the mixing tank, so there must be The mixed state of gas and liquid, the specific filling method is:

[0061] When the refrigerant leaks during the refrigeration cycle, the inlet pressure of the circulation compressor at point P drops. When the pressure at point P drops to a certain level, gas is added to the refrigeration cycle system through the mixing tank.

[0062] At the same time, when the refrigerant leaks during the refrigeration cycle, the liquid level of the separator at point L drops. At this time, the liquid refrigerant contained in the mixing tank is filled into the refrigeration cycle system from the separator position, that is, from figure 1 Fill the middle ① with canned liquid refrigerant.

[0063] After the refrigerant of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com