Device and method for measuring high depth-diameter ratio microporous recast layer on transparent material

A high aspect ratio, transparent material technology, applied in the field of optical measurement, can solve the problems of inability to accurately measure the quality of micropores, inability to obtain the thickness of the recast layer, etc., and achieve the effects of fast measurement speed, convenient measurement and simple device structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

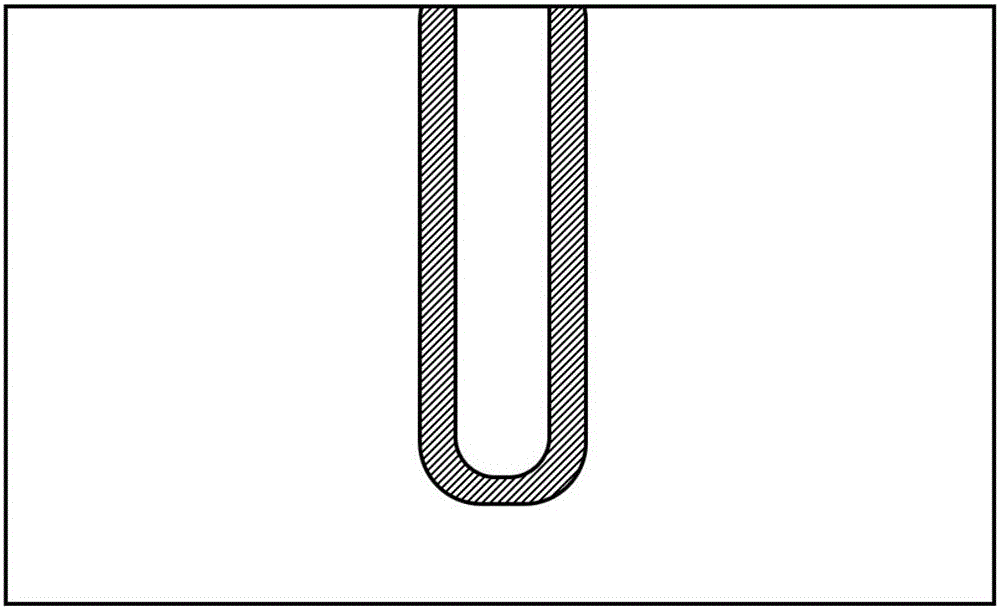

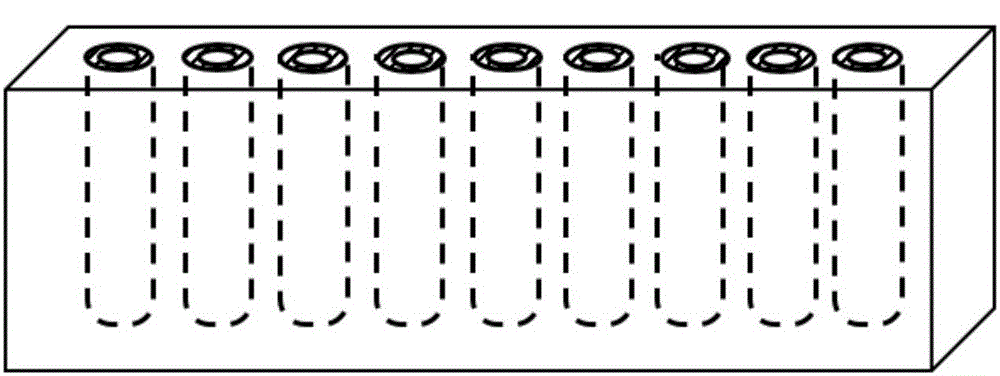

[0035] During the process of microhole processing, considering the influence of thermal effect, impact stress, etc., the density and lattice structure of the material around the microhole will change, which will lead to changes in the optical properties of the surrounding area of the microhole. Therefore, the thickness of the recast layer can be determined by measuring the change of the refractive index in the peripheral area of the microhole. Due to the small size of a single microhole, it is difficult to measure directly, so we propose a method to process a large number of microholes into a grating structure, and then measure the optical properties of the grating (mainly measure the zero-order diffraction efficiency of the grating), and calculate the To determine the method of refractive index around the microhole.

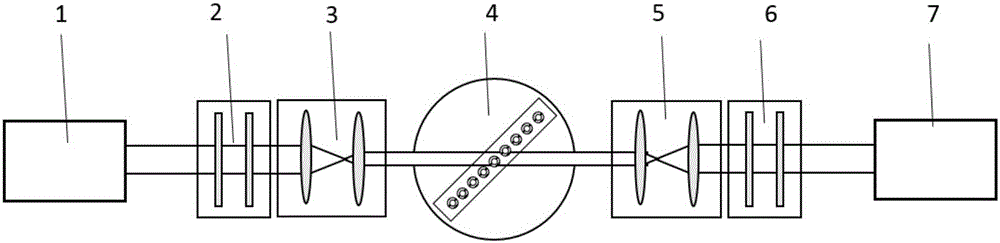

[0036] The structure of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com