Liquid level detection and adjustment method with solar power supply based on single-chip microcomputer

A technology for solar power supply and liquid level detection, which is applied in liquid level control, control/regulation systems, collectors, etc., and can solve problems such as liquid tilting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A liquid level detection and adjustment method designed based on a single-chip microcomputer using solar power supply, comprising the following steps:

[0030] 1) When the power supply starts, the sunlight shines on the photovoltaic panel, and the photovoltaic panel converts the light energy into electrical energy, and then further collects and transmits the electrical energy to the booster circuit through the internal circuit, and the booster circuit boosts the voltage and performs rectification and filtering , the DC voltage after rectification and filtering is supplied to the central processing unit through the power supply circuit, so that the central processing unit starts to work;

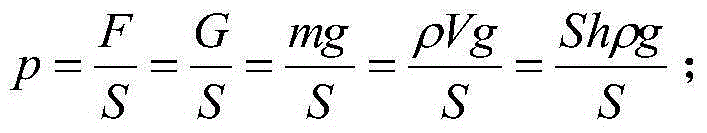

[0031] 2) Acquisition and detection of liquid level information. A pressure sensor for testing the liquid level value is placed inside the liquid. The liquid acts on the surface of the pressure sensor and generates a pressure value. The pressure sensor converts the pressure value into a...

Embodiment 2

[0036] This embodiment is further optimized on the basis of the above embodiments. Further, in order to better realize the present invention, when the power supply is started, it also includes a backup power supply mode, and the backup power supply mode is generated by photovoltaic panels. The abundant electric energy will be stored in the battery pack through the power control circuit. When the light intensity is not enough to generate electricity or at night, the battery pack will release the electric energy stored inside, and after the power control circuit transforms and stabilizes the voltage, it will be supplied to the central processing through the power supply circuit. device.

Embodiment 3

[0038] This embodiment is further optimized on the basis of any of the above-mentioned embodiments. Further, in order to better realize the present invention, it also includes a background control step. The background management center will issue a collection instruction to the central processing unit, and the central processing unit will Process the collection instruction and complete corresponding operations such as liquid level collection, liquid level adjustment, and liquid level optimal value setting according to the collection instruction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com